allied

academies

Page 34

Journal of Industrial and Environmental Chemistry

|

Volume 2

GREEN CHEMISTRY &

TECHNOLOGY

7

th

International Conference on

J u n e 1 8 - 2 0 , 2 0 1 8 | D u b l i n , I r e l a n d

Jakob Köchermann et al., J Ind Environ Chem 2018, Volume 2 | DOI: 10.4066/2591-7331-C1-002

PRODUCTION OF FURFURAL FROM

D-XYLOSE AND ORGANOSOLV

HEMICELLULOSE IN WATER/ETHANOL

MIXTURES

Jakob Köchermann, J Schreiber

and

M Klemm

DBFZ German Biomass Research Centre gGmbH, Germany

I

n recent years the production of furfural fromD-xylose and hemicellulose

richstreams fromthepulpandpaper industrywereextensivelydiscussed.

However, one problem that has always been described was the formation

of insoluble humins by self- and cross-polymerization of furfural. Due

to these side reactions the product yield and selectivity decreases.

Therefore, the use of biphasic systems or ionic liquids was investigated

to avoid this issue. Promising results have been shown but such systems

could by costly due to expensive solvents and the subsequently recovery

processes. Another approach to suppress polymerization of furfural is

the usage of alcohol/water mixtures as reaction medium. The alcohol

can react with the sugars and stabilize the reactive intermediates. For

our exploration as reaction medium ethanol/water with different mass

ratios were tested. Xylose was used as model compound for organosolv

hemicellulose and sulphuric acid as homogeneous catalyst. The

experiments were conducted in a thermostatically heated 500 mL stirred

batch reactor at three temperatures (180, 200 and 220°C). To avoid the

heating phase, the xylose was dissolved in water and transferred in a

liquid charging pipette made of stainless steel. The educt solution was

added to the ethanol/water mixture only after reaching the reaction

temperature. Immediately after addition, a first sample was taken by a

liquid sample valve with dip tube. Five more samples followed after 5, 15,

30, 60 and 180 min. Afterwards the reactor was cooled down to ambient

by the thermostat as fast as possible. Subsequently the insoluble humins

were separated from the reaction medium by vacuum filtration. The

process liquor samples were analysed by liquid chromatography (HPLC-

DAD) and the humins were quantified by weighing. Since ethanol is used

as solvent for the organosolv process, the hemicellulose stream after the

digestion contains residues of that alcohol. Therefore, we were interested

on furfural polymerization suppress capacity of different ethanol/water

mixtures. This approach has an interesting benefit since after furfural

separation ethanol/water stream can be reused for the organosolv

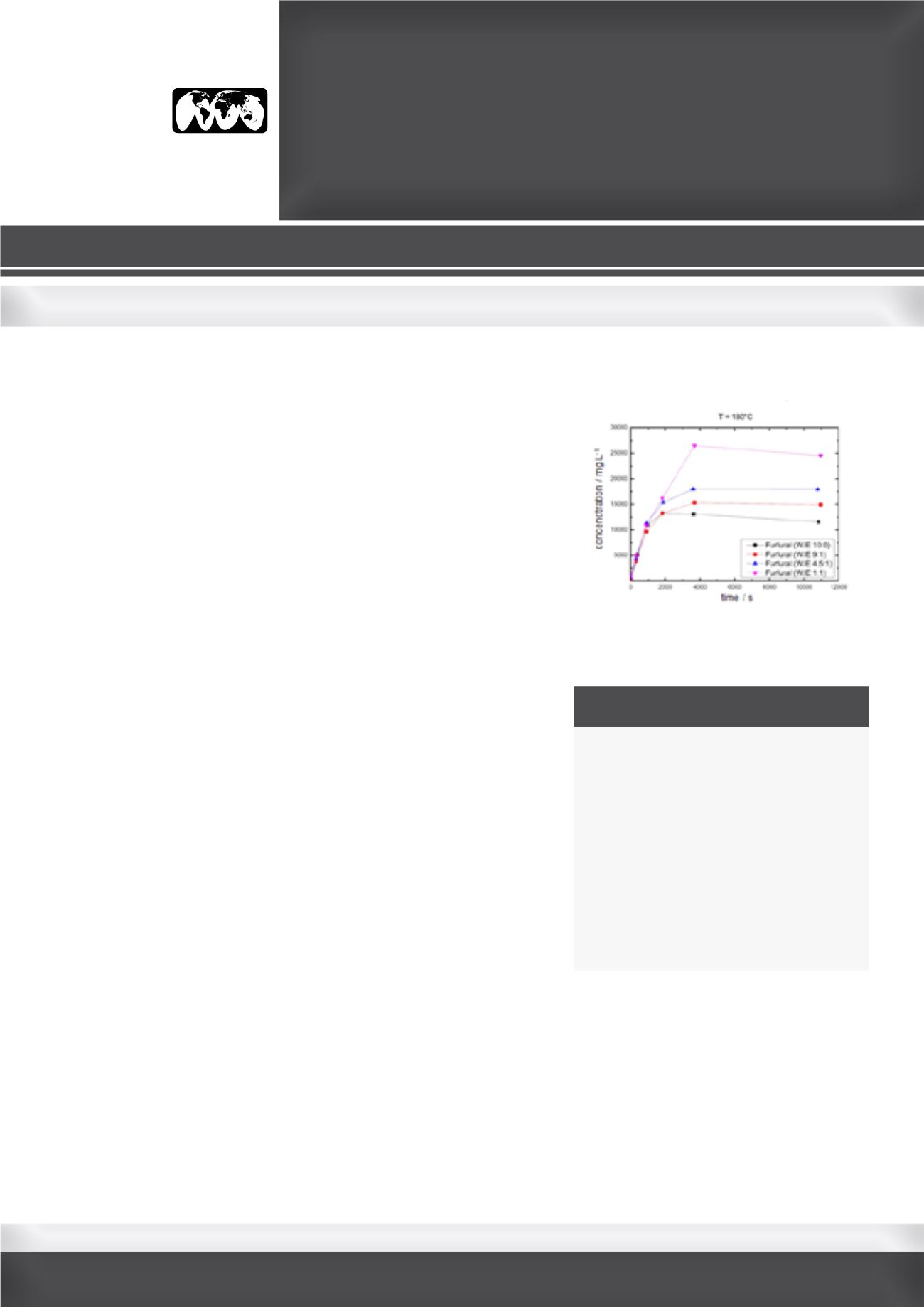

process. Preliminary results show a correlation between the ethanol/

water ratio and the amount of formed humins. The ethanol content has

also a strong influence and leads to an increase of furfural yield (Fig.1).

Furthermore, reference experiments with pure water were conducted. The

Jakob Köchermann studied chemical engineer-

ing at the Karlsruhe Institute of Technology (KIT)

and Technical University of Dresden (TUD). He

received his diploma (equiv. to MSc) in 2014 at

TUD. In 2015 he joined German Biomass Re-

search Center, where he worked until 2016 as

research fellow, focusing on hydrothermal con-

version of lignocellulosic biomass. Since 2016

he is PhD fellow at German Biomass Research

Center. Within the framework of his PhD thesis,

Jakob Köchermann works on hydrothermal

conversion of organosolv hemicellulose and xy-

lose to furfural.

jakob.kö chermann@dbfz.deBIOGRAPHY

results are promise for further explorations

with real organosolv hemicellulose hat should

be carried out in the next step.

Figure: Furfural concentration at various

water/ethanol mass ratios and a reaction

temperature of 180°C