allied

academies

Page 50

Journal of Industrial and Environmental Chemistry

|

Volume 2

GREEN CHEMISTRY &

TECHNOLOGY

7

th

International Conference on

J u n e 1 8 - 2 0 , 2 0 1 8 | D u b l i n , I r e l a n d

Filipa B Pimentel et al., J Ind Environ Chem 2018, Volume 2 | DOI: 10.4066/2591-7331-C1-002

TOTAL PHENOLICS OF

GRACILARIA

VERMICULOPHYLLA

: OPTIMIZING

EXTRACTION PROCEDURES USING

GREEN METHODOLOGIES

Filipa B Pimentel, Rita C Alve

and

M Beatriz P P Oliveira

University of Porto, Portugal

S

eaweeds are an important source of natural compounds with

recognized health benefits. One of the world’s most cultivated and

valuable seaweed is

Gracilaria

. This species is mainly cultivated and

harvested to extract phycocolloids, providingmore than 50% of the world’s

supply of the agar used by the food and cosmetic industries. The interest

in this species goes beyond this, taking into account its composition in

secondary metabolites with biological activity, which include phenolics.

Overall, these compounds are presumed to protect algal thalli from UV

radiation and to act as free-radical scavenging agents. This study aimed

to optimize an extraction protocol, using green chemistry principles, for

further quantificationof the total phenolics of

G. vermiculophylla

. The dried

samples, produced in an Integrated Multi-Trophic Aquaculture (IMTA)

system (Aveiro, Portugal), were thoroughly ground and homogenized prior

to analysis. Samples were submitted to several extraction conditions in

which the ratio of sample:solvent:time of extraction were tested, varying

one parameter at a time. The extraction procedure was optimized using

water as the extraction solvent in the following ratios: 1:30, 1:40 and 1:50

(w:v), during 30, 60, 90 up to 120 minutes, at room temperature. Some of

the protocols comprised re-extractions of the samples every 30 minutes,

while in others the extraction was continuous for the stipulated period of

time. Once the optimum extraction conditions were reached, the same

protocol was applied to the samples, using two other solvents: an hydro-

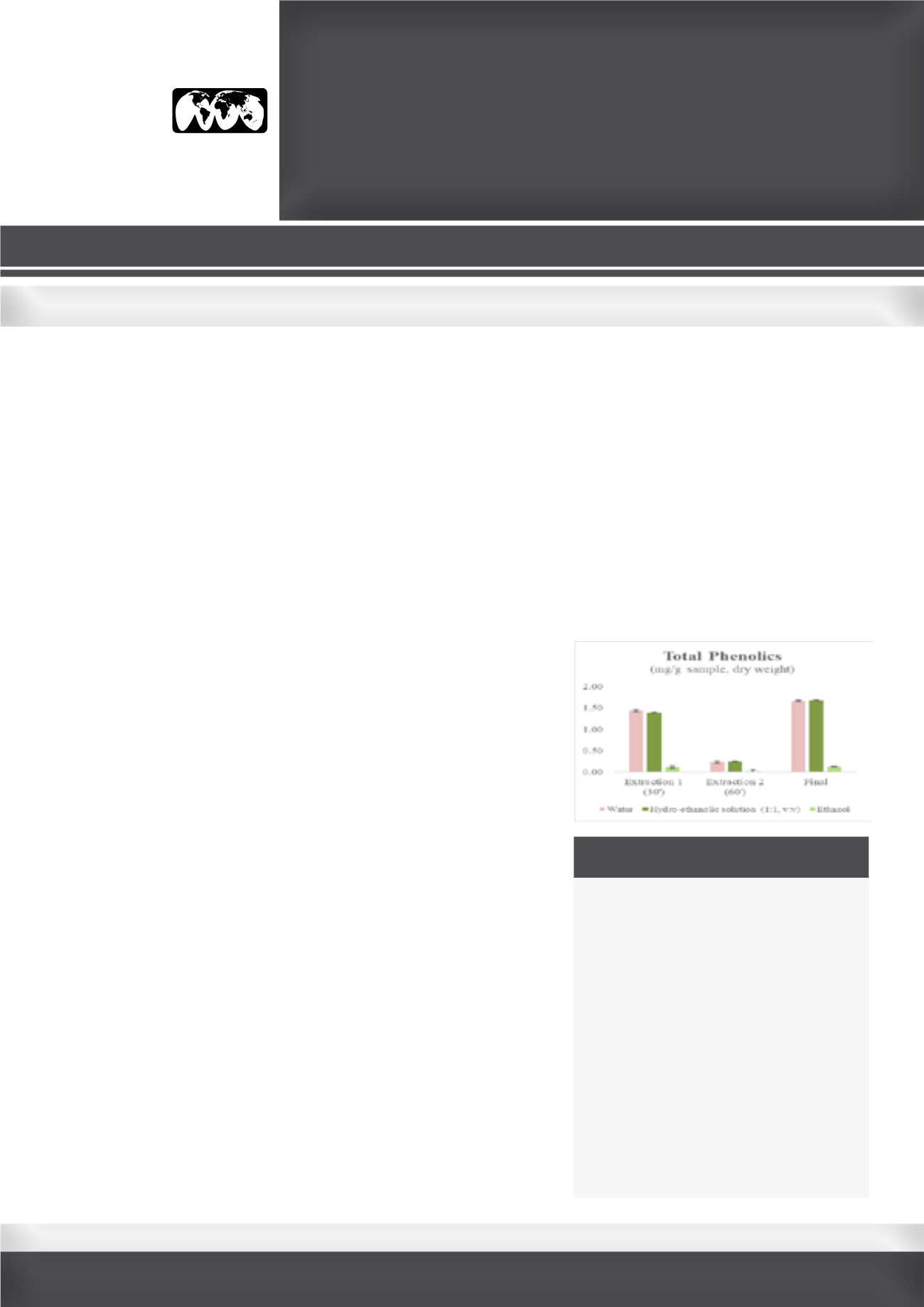

ethanolic solution (1:1, v:v) and ethanol. Results of the optimization

protocols using water as the extraction solvent show that the total

phenolics (TP) varied between 0.88±0.05 and 1.66±0.03 mg/g sample

(dry weight). The higher amounts of TP were obtained at a ratio of 1:40

(w:v) for 30 minutes with an additional 30 minutes re-extraction with ¼

of the total volume. Continuous extractions did not present advantages

over protocols comprising re-extractions over the time. In fact, in most

cases, a slight decrease of the TP is observed over time, probably due to

the degradation of the compounds. Comparing the water and the hydro-

ethanolic solution, in the first extraction, water was more efficient, but, at

the end of the process, there were no significant differences between the

amounts of TP in both solvents (1.66±0.03 and 1.68±0.03 mg/g sample

dw, respectively; p<0.05). Ethanol was the least efficient solvent to

extract TP (0.12±0.0 mg/g sample dw). The present work was designed

Filipa B Pimentel is a PhD student in Pharma-

ceutical Sciences (Nutrition and Food Science

Speciality) at the Faculty of Pharmacy of the

University of Porto, Portugal. Since 2012, she

is a researcher of REQUIMTE (Rede de Quími-

ca e Tecnologia), the largest network in Chem-

istry and Chemical Engineering established in

Portugal, which is focused on the development

of Sustainable Chemistry. Her research activi-

ties have been developed at the Department of

Chemical Sciences of the Faculty of Pharmacy

of the University of Porto in the food chemistry

and nutrition fields. She has 21 publications,

cited over 150 times. Formerly, she completed

her degree in Nutrition Sciences at the Faculty

of Nutrition and Food Sciences of the University

of Porto in 2004, and a Master in Food Service

Management from the same Faculty in 2011.

filipabpimentel@gmail.comBIOGRAPHY

to investigate the optimum extraction

protocol of the TP of

G. vermiculophylla

, using

green chemistry principles. The optimum

conditions were selected after combining

the following parameters: the recovery of

the maximum amount of TP, using the eco-

friendliest solvent at the lesser amounts

possible, during the shortest period of time.

In this case, this conducted us to select water

as the extractor solvent, using the ratio of

1:40 (w:v) for 30 minutes with an additional

30 minutes re-extraction with ¼ of the total

volume. This process allows the recovery of

natural seaweed-derived antioxidants, which

can be safely used for food and cosmetics

applications.