Page 15

Journal of Biomedical Research | ISSN: 0976-1683 | Volume 30

allied

academies

March 14-15, 2019 | London, UK

T issue Engineer ing, Stem Cel ls and Regenerat ive Medicine

Cel l and Gene Therapy

World Congress on

International Conference on

&

Joint Event

Introduction:

A lot of efforts have been directed to the creation

of functional knee cartilage tissue in the lab. The lack of tissue

regeneration in human beings and the deficiency of allogenic

transplants in addition to the increasing of life expectancy make

this problem to be considered as one of the most important

ones of humanity in the current era.

Joint cartilage is a connective tissue that lacks vascularization

and innervation and is composed of a specific extracellular

matrix. The healing process of cartilage tissue is slowand results

in a fibrous scar-like tissue that lacks the functional properties

of the hyaline cartilage leading to further tissue degeneration.

However, the results obtained are still far away fromthe desired.

For the creation of a living tissue it is crucial the bioprinting

process but also the maturation of the construct. Replicating

the human being adult conditions

in vivo

in the lab or the stimuli

that occur in embryogenesis could improve the results of tissue

engineering towards the clinical application of the technology.

Materials and methods:

Here, we propose a unique approach

to create functional knee cartilage tissue starting from bio

printed constructs (fabricated using bioprinting) and a device

that mimic the physiology and apply the right mechanical

conditions of the structure to be replaced and through the

maturation procedure, applying the right stimuli, creates a

functional tissue. We think that the best stress distribution is

the real one and other approaches fail as do not mimic the real

conditions happening in nature.

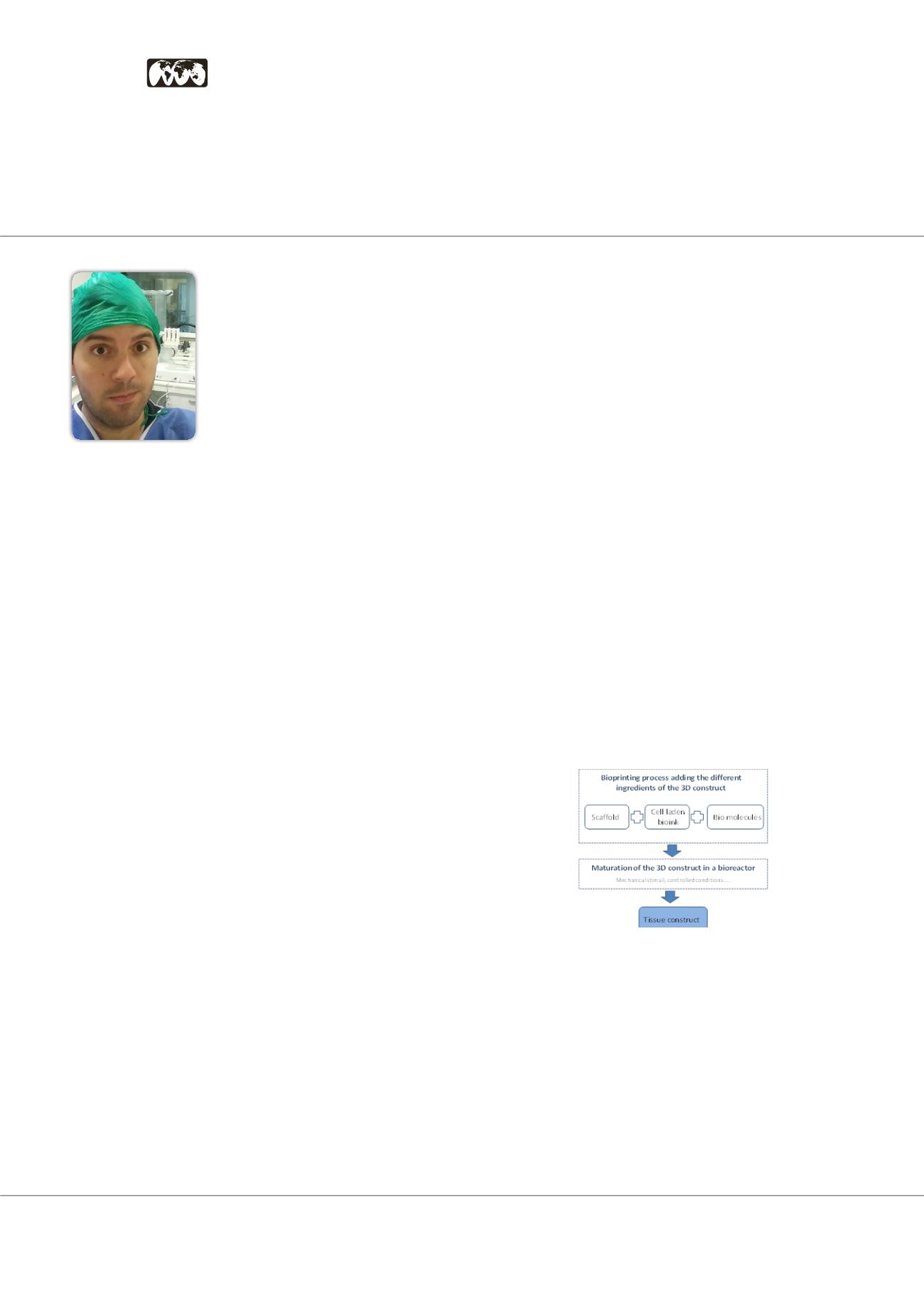

Results and discussion:

In the present work, we show amethod

that helps to create functional knee cartilage tissue after

bioprinting. For the creation of a living tissue it is crucial the

bioprinting process and the ingredients selected to achieve the

objective to create a functional specific tissue (first block of the

image). But also, the maturation procedure applied to the 3D

cell laden constructs, that is evenmore important (second block

of the image). If we think about bioprinting as a technology to

recreate all the structure in the same form as shown in a living

knee cartilage tissue, we are going to fail. We have to think on

bioprinting as a way of creating cell laden 3D constructs as a

precursor of a functional tissue. The maturation and tissue

formation process will be as important or even more than the

bioprinting one. Considering the strategies of both blocks in the

diagram will be crucial to obtain the desired functional knee

cartilage tissue.

Conclusion:

The stress distribution is crucial as stimuli to create

the right tissue. Also, the scaffold architecture as it will affect

the stimuli distribution and other important parameters as the

biodegradation time. The selection of the right ingredients and

the bioprinting procedure is very important in the success of

the creation of functional knee cartilage tissue, as well as the

maturation procedure applied to the 3D cell laden constructs is

evenmore important. This approachopens awide researcharea

for tissue engineers to develop protocols with different stimuli

to create functional knee cartilage tissue after bioprinting.

Speaker Biography

Jose Manuel Baena completed his PhD in Biomedicine from the University of Granada,

Spain,MScEngineeringfromPolytechnicUniversityofValencia,SpainandTUBraunschweig,

Germany and MSc from Oxford Brookes University, UK. He serves as scientific coordinator

of the tissue engineering and 3D printing platform (PITI3D), IDIPAZ, Hospital Universitario

de La Paz, Madrid, Spain and he is research associate in the group “Advanced therapies:

Differentiation, regeneration and cancer” IBIMER, CIBM, University of Granada, Spain. He

has published several research papers and 1 book. He has presented his work in dozens of

congresses around the globe. As a biotech entrepreneur, he founded BRECA Health Care,

pioneer in 3D printed custom-made implants for orthopaedic surgery and REGEMAT 3D,

a leader in the bioprinting industry. He is an expert in innovation, business development

and internationalization, lecturer in some business schools and also, he is passionate about

biomedicine and technology.

e:

josbaema@gmail.comJose Manuel Baena

REGEMAT 3D, Spain

Manufacturing of functional tissues

in vitro

using bioprinting and bioreactors:

Application in knee cartilage regeneration

Jose Manuel Baena

, Biomed Res, Volume 30

DOI: 10.4066/biomedicalresearch-C1-024