allied

academies

Materials-Metals 2017

Page 38

November 16-17, 2017 Paris, France

13

th

Annual Conference on

Materials Science, Metal and Manufacturing

Journal of Materials Science and Nanotechnology

Volume 1 Issue 2

Electrodeposition of tin on copper from choline

chloride based ionic liquids

Xiangxin Xue

1,2

, Xiaozhou Cao

1,2

, Lulu Xu

1,2

, Xiaoyu Zhang

1,2

, Qiuyue

Li

1,2

, Yuanyuan Shi

3

, He Yang

1,2

and

Tao Jiang

1,2

1

Northeastern University, China

2

Key Laboratory of Recycling Science for Metallurgical Resource, China

3

Chinalco Shenyang Non-ferrous Metal Processing Co., Ltd, China

T

in and its alloys are widely used in various industrial

applications including electronics, light engineering,

automotive and building materials due to their non-

toxic, corrosion resistant and ductile properties. The

electrodeposition of Sn and Sn alloys is widely practiced in

aqueouselectrolytesincludingsulphuricacid,methanesulronic

acid, phenolsufonic acid and citric acid. However,

electrodeposition of Sn presents the low current efficiency

from aqueous solutions due to a narrow electrochemical

window of water. Ionic liquid has wide potential window,

high thermal stability, good ionic conductivity and negligible

vapor pressure as electrolyte for various electrochemical

process. The electrodeposition of Sn on copper substrate

was investigated using 0.2mol/L SnCl

2

∙2H

2

O dissolved in the

eutectic mixture of choline chloride and urea (1:2molar ratio).

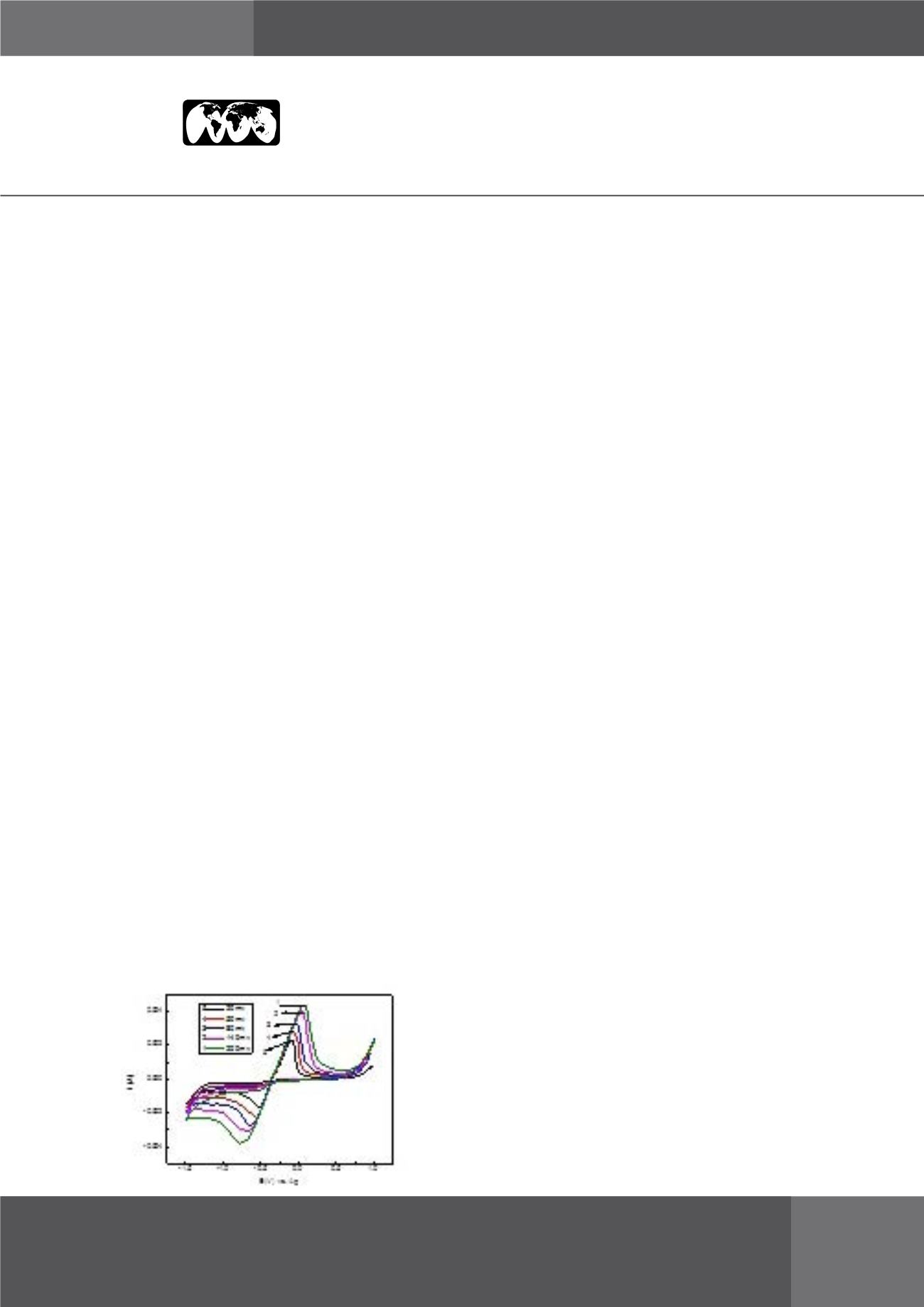

A typical voltamperogram at different scan rate is shown in.

The curve displays a couple of well-define cathodic and anodic

peaks which is a typical metal deposition-stripping process.

The reduction peak potential shifts to negative potentialsi

with the increase of scan rates, which was associated with

quasi-reversible electrochemical reactions. The cathodic

peak current versus the square root of the sweep rate for the

cyclic voltammograms are shown in Figure 2. It can be seen

that the plot displays a liner relationship, indicating that the

reduction reaction was a diffusion-controlled process. The

microstructure of Sn electrodeposits at different temperatures

was analyzed by scanning electron microscopy (SEM) in

Figure 3.The results showed that the deposits are compact, and

the particles began to grow with the increase of temperature.

Figure:

Cyclic voltammograms of 0.2mol/L SnCl

2

∙2H

2

O on

Mo electrode in urea-choline chloride at 343K under different

scan rates.

Recent Publications

• Anicai L, Petica A, Costovici S, Prioteasa P, Visas T

(2013) Electrodepostion of Sn and NiSn alloys coating

using choline chloride based ionic liquids-evaluation of

corrosion behavior. Electrochimica Acta 114:868-877.

• Walsh F C, Low C T J (2016) A review of developments

in the electrodeposition of tin. Surface & Coatings

Technology. 288:79-94.

• Anicai L, Costovici S, Cojocare A, Manea A, Visan T

(2015) Electrodeposition of Co and CoMo alloys coatings

using choline chloride based ionic liquids-evaluation of

corrosion behavior. Transactions of the IMF. 93(6):302-

312.

• Sakita A M P, Noce R D, Fugibara C S, Benedetti A V

(2016) On the cobalt and cobalt oxide electrodeposition

froma glyceline deep eutectic solvent. Physical Chemistry

Chemical Physics. 18(36):25048-25057.

• Maltanava H M, Vorobyova T N, Vrublevskaya O N

(2014) Electrodeposition of tin coatings from ethylene

glycol and propylene glycol electrolytes. Surface &

Coatings Technology. 254:388-397.

Biography

Xiangxin Xue received his BS, MS and PhD in 1977, 1983 and 1990 from

Institute of Metallurgy and Physical Chemistry, Ferrous Metallurgy at

Northeastern University. Since June 1998, he became a Professor and Doctoral

Tutor. In 2000, he set up the Institute of Metallurgy Resource and Environment

Engineering (now department of resource and environment) at Northeastern

University. His current research focuses on the comprehensive utilization of

metallurgy resource and green metallurgy process flow innovation.

xuexx@mail.neu.edu.cnXiangxin Xue et al., Mater Sci Nanotechnol 2017, 1:2