Page 19

O c t o b e r 1 9 - 2 0 , 2 0 1 8 | T o k y o , J a p a n

Materials Summit 2018 & Separation Summit 2018

Materials Science and Nanotechnology

|

Volume 2

ADVANCED MATERIALS AND POLYMER SCIENCE

SEPARATION TECHNIQUES

&

International Conference on

International Conference and Expo on

Joint Event on

OF EXCELLENCE

IN INTERNATIONAL

MEETINGS

alliedacademies.comYEARS

Takeshita M et al., Mater Sci Nanotechnol 2018, Volume 2

DE WAVE POWER GENERATORS

Takeshita M

1

, Waki M

2

, Chiba S

3

, Uejima M

1

, Arakawa K

1

,

Ueno M

1

and

Fujita K

4

1

Zeon Corporation, Japan

2

Wits Inc., Japan

3

Chiba Science Institute, Japan

4

Tohoku University, Japan

I

ncrease in world population and the accompanying surge in demand for

energy, food andwater, aswell as the sudden increase in energy consumption

caused by recent industrial development and betterment of life standards in

newly developing countrieswill accelerate global warming. Among the diverse

measures proposed to meet our energy needs, the use of renewable energy

is receiving increasing attention. Especially, the wave power generation has

attracted attention as one of useful utilization methods for ocean energy.

However, the conventional wave generators are large, expensive, and unable

to efficiently generate electric power with small amplitudewaves, limiting their

widespread usage. To solve these problems, we will discuss the possibilities

for a wave power generator using dielectric elastomer (DE) artificial muscle

recently developed as a novel method for harvesting renewable energy. DE

artificial muscle is a new smart material technology with characteristics and

properties not seen in other materials. The basic element of DEs is a very

simple structure comprised of thin polymer films (elastomers) sandwiched

by two electrodes made of a stretchable material. DEs can operate as an

electrically-powered actuator. When a voltage difference is applied between

the electrodes, they are attracted to each other by electrostatic forces leading

to a thickness-wise contraction and plane-wise expansion of the elastomer.

The use of DE actuator in the reverse mode, in which deformation of the

elastomer by external mechanical work is used to generate electrical energy,

has been gaining more attention. As DE is very light, inexpensive, and easily

formed into multiple layered structures, it can make a very simple and robust

direct drive wave power system that is economically viable. DE has moved

now from the research and development stage to the commercial domain

with research and development on practical applications, and furthermore to

the mass production stage.

Takeshita M has completed his graduation from the

Tokyo Institute of Technology Interdisciplinary Gradu-

ate School of Science and Engineering in 2003 with a

master’s degree in Engineering studies. He is currently

a Senior Researcher at the CNT Laboratory Materials

Research Team, Research and Development Center,

Zeon Corporation. He wrote many papers related to

CNTs.

M.Takeshita@zeon.co.jpBIOGRAPHY

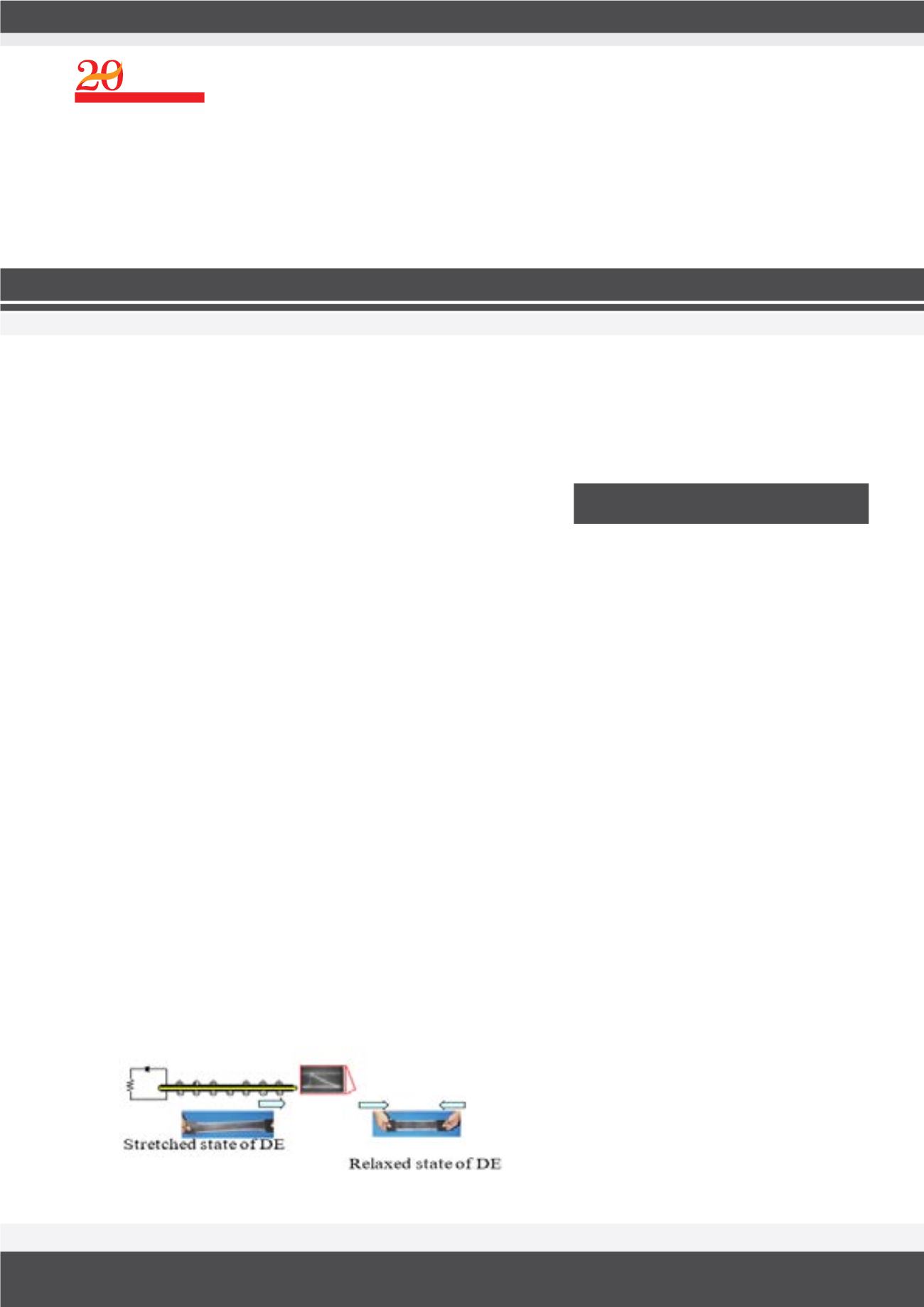

Figure.1: Operating principle of dielectric

elastomer power generation; the DEG is basically

a stretchable capacitor. If a charge is applied to

the DEG in the stretched state, then work done

by the contracting elastomer is converted into

electrical energy (as illustrated by the voltage

across the resistor in the right illustration).