Page 15

Notes:

allied

academies

February 25-26, 2019 | Paris, France

Materials Science and Engineering

2

nd

International Conference on

Journal of Materials Science and Nanotechnology | Volume 3

S

hapeMemoryAlloy (SMA) has beenattracting the researchers

from different fields due to their superior properties. SMA is

categorized as smart material with unique class of alloy for its

ability to undergo large deformation as well as energy dissipation

capacitieswhilemaintainingasuperelasticresponseandreturning

to its original shape through stress removal (Super Elasticity) used

for new construction or through heating (Shape Memory Effect

“SME”) used for strengthening applications. This presentation

focuses on the use of SMA with the SME characteristics. The

SME represents the ability of the SMA to recover its original

shape after being deformed beyond the elastic limits through

heating. The strain recovered in this transformation process can

be utilized for prestressing applications. Therefore, by having

the pre-strained SMA reinforcement (bars or strips) attached

to the Reinforced Concrete (RC) members and then applying

heat above the activation temperature the SMA will recover the

inelastic strain and thus a presressing force will be developed

in the RC member. In other words, the pre-strained SMA itself

can be used as the supplementing prestressed reinforcement

in flexural strengthening of RC beams/slabs by eliminating the

use of specialized equipment such as hydraulic jacks. Another

strengthening application is confining RC columns using SMA

wires. This confinement technique relies on the recovery stress

generated as the SMA wire transforms to its recovery (un-

deformed) state. The confinement methodology simply involves

wrapping a pre-strained SMA wire along the perimeter of the

column. Then, heating the wire using an electrical current above

a predefined transformation temperature would trigger the

SME of the SMA that allows the wire to return to its original

state while a reactive force is created by the wires producing an

active confinement pressure. Findings from many researchers

added a valuable knowledge to the field of strengthening RC

structures and widened the potential applications of the SMA in

the structural engineering field.

Speaker Biography

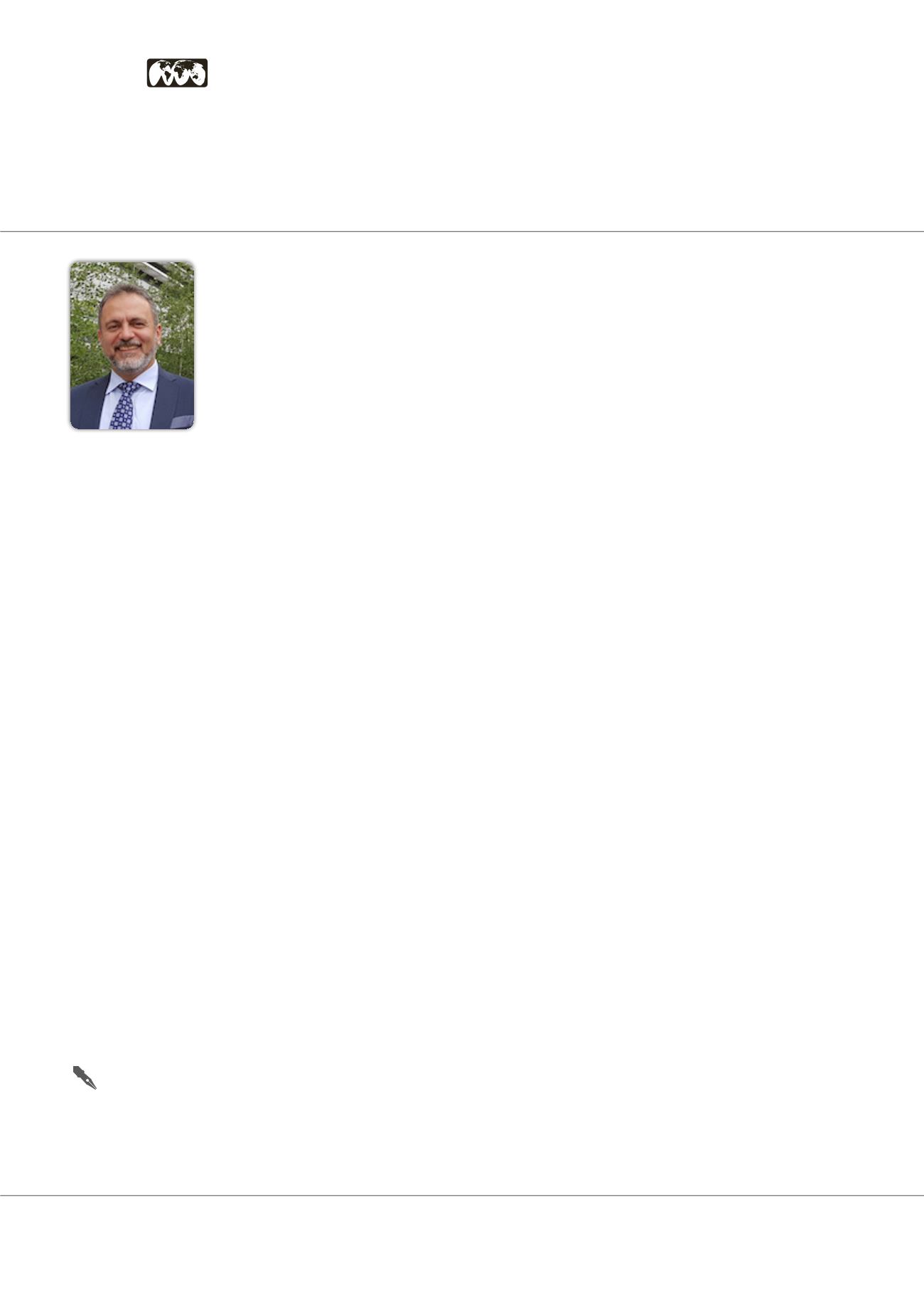

Raafat El-Hacha is a Professor of Structural Engineering at the University of Calgary in the

Department of Civil Engineering. His pioneer research has been recognized as pushing the

boundaryofknowledge inusing innovativeandsmartadvancedmaterialsforstrengthening

existing structures and for new construction, such as fibre reinforced polymers (FRP),

shape memory alloy, and ultra-high performance concrete for hybrid structural systems

in bridge applications and other structures. He published over 220 journal and conference

papers, co-authored 3 refereed design guidelines. Supervised and graduated 42 PhD and

MSc students. Served as guest editor for 3 journals and edited/co-edited 8 conference

proceedings. He is a Fellow of the International Institute for FRP in Construction (IIFC) and

the Canadian Society of Civil Engineers (CSCE). He is the recipient of several awards and

fellowships including the CSCE Casimir Gzowski Gold Medal, CSCE Excellence in Innovation

in Civil Engineering Award, IIFC President’s Award, Killam Professorship Award, Erasmus

Mundus International Fellowship (twice) and many others for his outstanding academic

and professional achievements.

e:

relhacha@ucalgary.caRaafat El-Hacha

University of Calgary, Canada

Strengthening concrete structures using shape memory alloy