allied

academies

Materials-Metals 2017

Page 19

November 16-17, 2017 Paris, France

13

th

Annual Conference on

Materials Science, Metal and Manufacturing

Journal of Materials Science and Nanotechnology

Volume 1 Issue 2

Mikko Kanerva at al., Mater Sci Nanotechnol 2017, 1:2

Build-up of new nature-mimicking materials using

automated simulation routines—the future trend?

Mikko Kanerva, Sanna Siljander

and

Jarno Jokinen

Tampere University of Technology, Finland

T

he current consumption of fossil fuel resources and respective

production of traditional polyolefin plastics has led to huge

clustering of plastics in oceans as well as in landfill sites. In

its simplicity, sole recycling will never solve the waste problems

because plastics will anyway be left unrecycled at a finite rate

due to the human nature. Biodegradable, isotropic polymer

blends are neither a complete solution for all applications

because their performance is far behind that of current high-

performance polymers, such as the ones of epoxy, vinylester,

aramid, and bismaleimide thermoset families. Basically all the

biodegradable polymeric systems for structural applications

are continuous fibre-reinforced plastics. In these composites,

either the reinforcement (e.g. bio-based fibres) or the

polymer matrix is the degradable component. The reinforcing

particles can have various forms and involve wood particles

and fibres, natural fibres (e.g. flax or hemp), clay, starch, and

cellulose. For high performance applications, the outcome

of these studies boils down to the fact that there is always a

distinctive compromise between a high bio-particle content and

good mechanical properties, or, in other words, the composites

represent a double-edged sword with some sustainability and

mechanical performance. However, a carefully adjusted mixture

of synthetic and natural fibres can result in a better mechanical

response, e.g. against impact loads, compared to composites

with only either type of reinforcement. Graphite as well as

carbon nanotubes have excellent electrical, mechanical and

thermal properties. For these reasons they are considered

to be used in many types of composites in the future.

Combining CNTs with cellulose has known to be eco-friendly,

efficient, low cost and non-metal based option. Applications of

CNT/cellulose composites usage are reported to be in the fields of

electromagnetic interference shielding, chemical vapour sensors

and in pressure sensing. Also, totally new species of advanced

’nat- ural’ materials are being developed. For example, the

nacre-mimetic materials are a type of nano-composite that

significantly benefits the synergetic arrangement of its rather

unique poly(vinyl alcohol)/clay building blocks. The maturity

of these materials is on a laboratory level and will take long until

their processing can reach commercial needs. Eventually, any

environment degrades the material properties of polymeric

systems. In order to create new high-performance composites,

the degradation behavior must be understood and controlled.

Especially the fibrous composite materials are challenging to

analyse considering the aging response. Even pure linear

anisotropic models will require nine engineering constants per

material not to mention the interface models to tie different

layers together, or the internal residual stress models.The

question from the numerical analysis point of view is how to

define relevant parameters when modelling the environmental

effects of laminate or an entire structure. This presentation will

deal with the application of automated simulation routines

to design new materials. Ex- amples of using Abaqus-Isight

(Simulia) coupling are presented for understanding the aging in

high-performance glass-fibre reinforced composites (Fig. 1(a)).

The focus in these cases are on the challenges of building up the

material model for a layered composite with correct interface

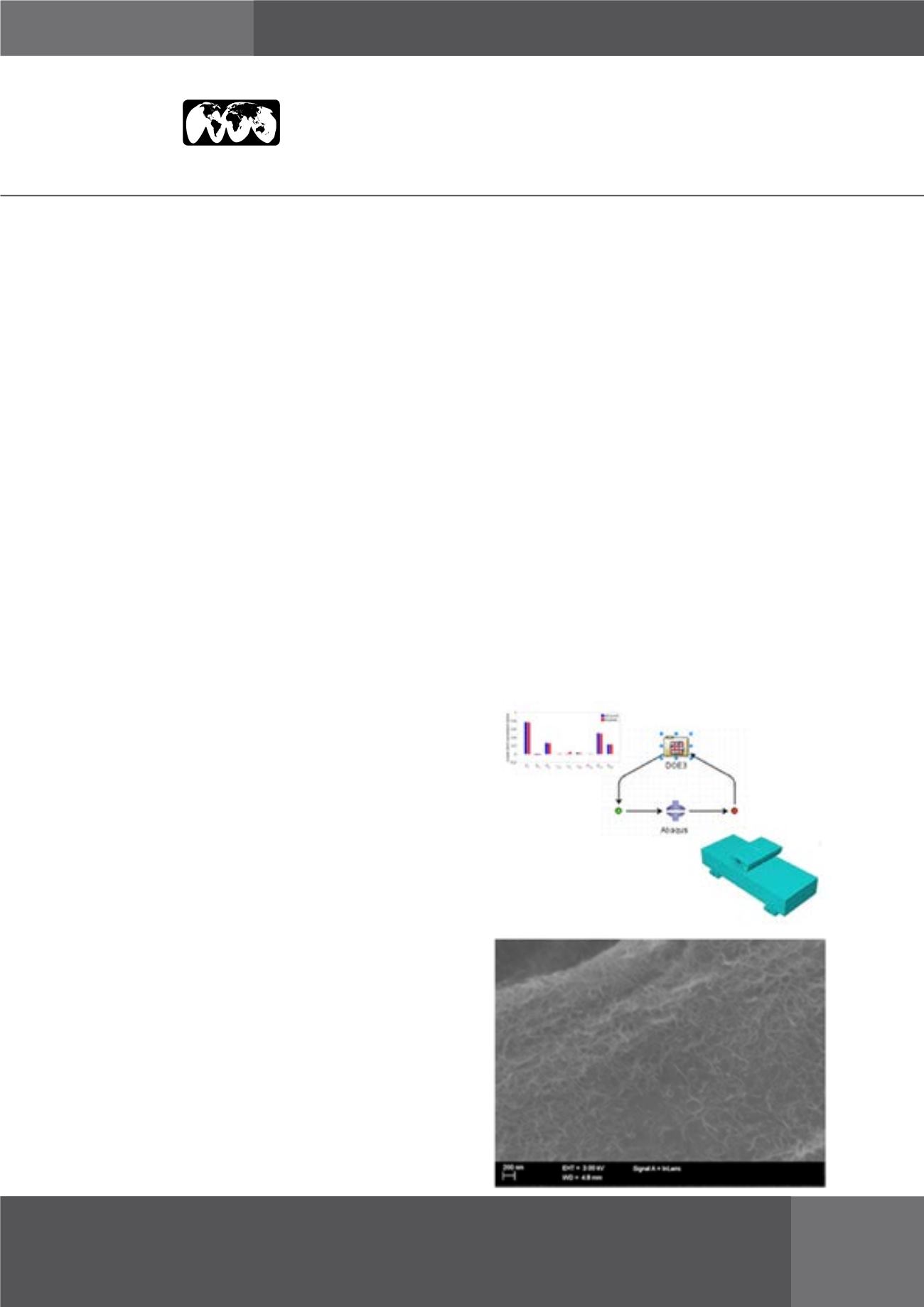

models. In the second part of the presentation, examples of

new materials with optimized nano-strengthening are presented

(Fig. 1(b)). Film preparation using nanofibrillated cellulose,

CNTs as well as electrospinning are described with emphasis

on the sonication models, particle-ratios and de-hydration. The

presentation will discuss the future trends in using autonomous

and smart numerical simulations to screenmost potential multi-

composites for optimized behavior in specific applications.