allied

academies

Materials-Metals 2017

Page 15

November 16-17, 2017 Paris, France

13

th

Annual Conference on

Materials Science, Metal and Manufacturing

Journal of Materials Science and Nanotechnology

Volume 1 Issue 2

Se-Young Jeong, Mater Sci Nanotechnol 2017, 1:2

Fabrication of wafer-scale grain boundary free Cu

single crystal film and copper oxide film by sputtering

method and its application

Se-Young Jeong

Pusan National University, Republic of Korea

C

opper thin films have been widely used as electrodes and

interconnection wires in integrated electronic circuits,

and more recently as substrates for the synthesis of graphene.

However, the ultra-high vacuum processes required for high-

quality Cu film fabrication, such as molecular beam epitaxy

(MBE), restricts mass production with low cost. In this work,

we demonstrated high-quality Cu thin films using a single-

crystal Cu target and sputtering technique; the resulting film

quality was comparable to that produced using MBE, even under

unfavorable conditions for pure Cu film growth. The Cu thin film

was epitaxially grown on an Al

2

O

3

(0001) substrate, and had high

crystalline orientation along the (111) direction. Despite the 10-

3

Pa vacuum conditions, the resulting thin film was oxygen free

due to the high chemical stability of the sputtered specimen from

a single-crystal target; moreover, the deposited film had > 5 X

higher adhesion force than that produced using a polycrystalline

target. We applied the technique fabricating the single crystal

thin film to the flexible transparent conducting electrodes, where

a micromesh/nanomesh structure was fabricated on a polyimide

substrate using UV lithography and wet etching. We also

succeeded to fabricate a wafer-scale graphene in the formation

of artificial single crystalline AB-BLG via aligned transfer of two

single-crystalline monolayers. Such single crystal copper film

was realized not only on the sapphire substrate, but also on the

PI, PET, and PC, which enabled to apply in the region of flexible

devices, metamaterial and of surface plasmonics. The important

advantage of this single crystal copper film is due to the natural

oxide layer with a thickness of around 2nm, which protects

further oxidation, so that the copper layer maintains clean even

for 2-3 years without any capping layer. Well-defined conditions

enabled the copper film to convert to Cu

2

O or CuO partially

or totally, which are transparent and p-type semiconductor. In

the partially oxidized case, the copper layer left beneath Cu

2

O

or CuO could be used as electrode. The color of the film varies

between transparent gold and opaque metallic scarlet depending

on the ratio of metal and oxides. Thanks to the grain free copper

thin film, the copper oxides also maintain high crystallinity.

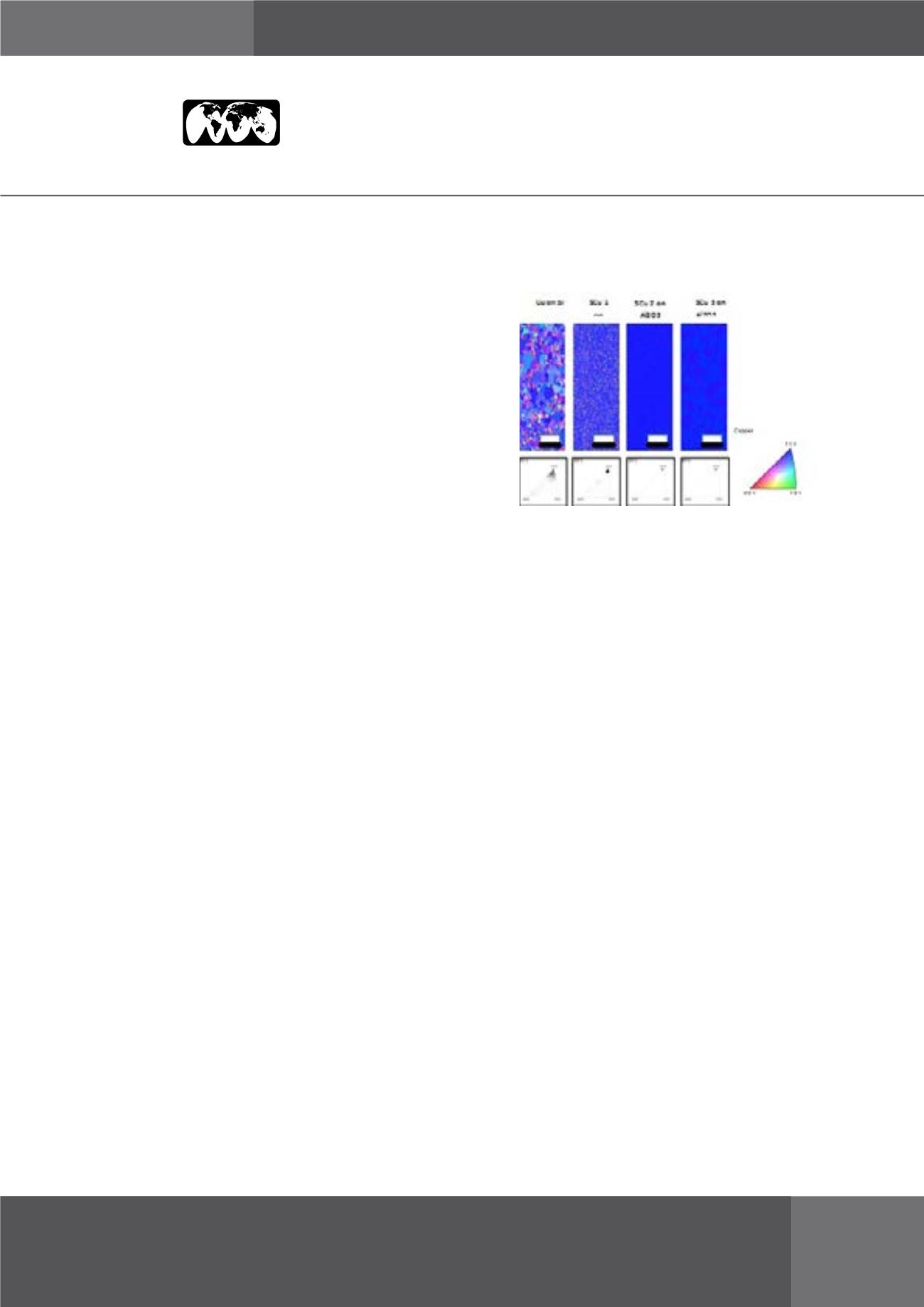

Figure 1:

The EBSD images of commercial copper film (Cu on

Si), single crystal copper film under unoptimized conditions

SCu

1

and SCu

2

) and single crystal copper film under optimized

condition (SCu

3

)

Recent Publications

• Nguyen VL, Perello DJ, Lee S, Nai CT, Shin BG, Kim JG,

Park HY, Jeong HY, Zhao J, Vu QA, Lee SH, Loh KP, Jeong

SY and Lee YH (2016) Wafer-scale single-crystalline AB-

stacked bilayer graphtene. Advanced Materials, 28: 8177-

8183.

• Lee S, Wi HS, Jo W, Cho YC, Lee HH, Jeong SY, Kim YI, Lee

GW (2016) Multiple pathways of crystal nucleation in an

extremely supersaturated aqueous potassium dihydrogen

phosphate (KDP) solution droplet, PNAS 113: 13618-13623.

• Kim WK, Lee S, Lee DH, Park IH, Bae JS, Lee TW, Kim

JY, Park JH, Cho YC, Cho CR, Jeong SY (2015) Cu Mesh

for Flexible Transparent Conductive Electrodes. Sci. Rep. 5:

10715-10722

• Kim JY, Oh MW, Lee S, Cho YC, Yoon JH, Lee GW, Cho CR,

Park CH and Jeong SY (2014) Abnormal Drop in Electrical

Resistivity after Impurity Doping of Single Crystal Ag. Sci.

Rep. 4: 05450-05454

• Phamcong D, Choi JH, Yun J. Bandarenka A. Kim J. Braun

P. Jeong SY, Cho CR (2017) Synergistically Enhanced

Electrochemical Performance of Hierarchical MoS2/

TiNb2O7 Hetero-Nanostructures as Anode Materials for

Li-Ion Batteries. ACS Nano 11: 1026-103.