allied

academies

Materials-Metals 2017

Page 34

November 16-17, 2017 Paris, France

13

th

Annual Conference on

Materials Science, Metal and Manufacturing

Journal of Materials Science and Nanotechnology

Volume 1 Issue 2

Cecile Reynaud et al., Mater Sci Nanotechnol 2017, 1:2

Growth of vertically aligned carbon nanotubes on

metallic surfaces

Cecile Reynaud

1

, F Nassoy

1,2

, M Pinault

1

, J Descarpentries

2

, P E Coulon

3

and

M Mayne L’Hermite

1

1

NIMBE-CEA, CNRS, Université Paris-Saclay, France

2

NawaTechnologies, France

3

LSI-Ecole Polytechnique, Université Paris-Saclay, France

F

orests of vertically aligned carbon nanotubes (VACNTs) are

attractive nanomaterials because of their unique structural,

electrical and thermal properties. However, many applications

require their growth on metallic substrates. Catalytic chemical

vapor deposition (CCVD) is the best method to grow them

but the catalytic particles can diffuse rapidly into the metal

subsurface and thus become inactive. In this communication,

I will address this issue through the recent results obtained in

our laboratory. I will show how it is possible to grow VACNT on

carbon fibers, stainless steel and aluminum surfaces by a single-

step process, namely the aerosol assisted CCVD method, where

the catalyst and carbon precursors are injected simultaneously.

In the case of aluminum, due to its low melting temperature,

the synthesis of VACNT requires a significant reduction in the

growth temperature as compared to conventional substrates. Our

results show that, with our single-step process, it is possible to

obtain clean, long and dense VACNTs, with a growth rate at the

best level compared to the state of the art at such low temperature.

A particular attention has been paid to the study of the CNT/

Al interface with various analysis technics: SEM, TEM, EDX,

XPS, GDOES. The results suggest the crucial role of the interface

for an efficient and reproducible VACNT growth. Finally, I will

show that the aerosol-assisted CCVD process can be scaled-up

to enable the fabrication of innovative ultracapacitors based on

VACNTs grown on aluminum foils.

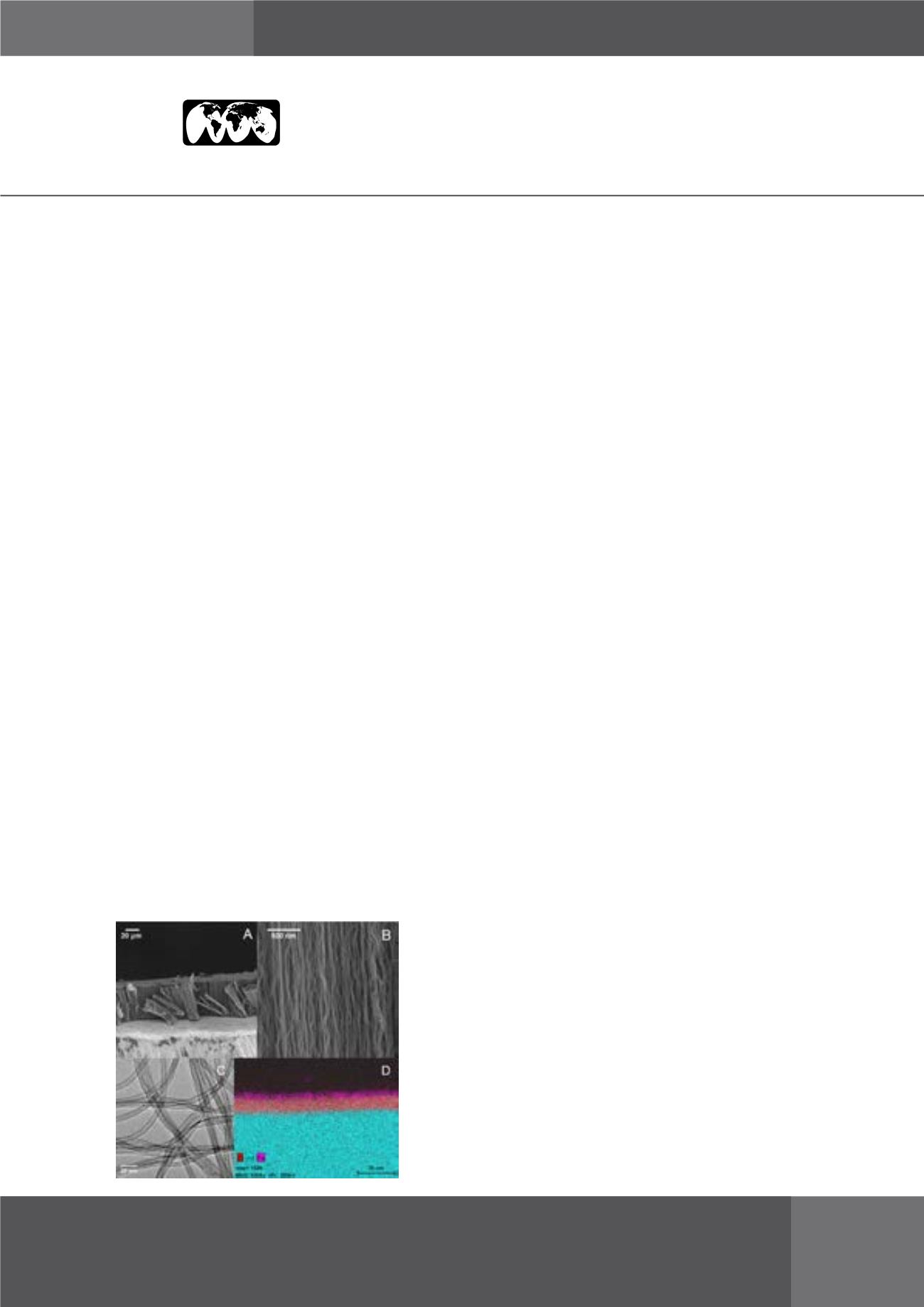

Figure:

SEM (A, B) and TEM (C) images of VACNT on

aluminum substrate. STEM/EDX (D) image of CNT/Al interface

(blue: aluminum, red: oxygen, purple: iron).

Recent Publications

• M Delmas, M Pinault, S Patel, D Porterat, C Reynaud, M

Mayne L’Hermite (2012) Growth of long and aligned multi-

walled carbon nanotubes on carbon and metal substrates.

Nanotechnology. 23(10):105604.

• P Landois, M Pinault, S Rouzière, D Porterat, C Mocuta,

E Elkaim, M Mayne L’Hermite, P Launois, In situ time

resolved wide angle X-Ray diffraction study of nanotube

carpet growth: nature of catalyst particles and progressive

nanotube alignment. Carbon. 7:0-10.

• C Castro, M Pinault, D Porterat, C Reynaud, M Mayne

L Hermite. The role of hydrogen in the aerosol-assisted

chemical vapor deposition process in producing thin

and densely packed vertically aligned carbon nanotubes.

Carbon. 61:585-594.

• P Boulanger, L Belkadi, J Descarpentries, D Porterat, E

Hibert et. al. (2013) Towards large scale aligned carbon

nanotube composites: an industrial safe-by-design and

sustainable approach. J. Phys. Conf. Ser. 429:(1):1-12.

• S Lagoutte, P H Aubert, M Pinault, F O Tran Van,

M Mayne-L ’Hermite, C Chevrot (2014) Poly(3-

methylthiophene)/vertically aligned multi-walled carbon

nanotubes: electrochemical synthesis, characterizations

and electrochemical storage properties in ionic liquids.

Electrochim. Acta. 130:754-765.

Biography

Cecile Reynaud has her expertise in the synthesis and chemical physics of

nanomaterials. Her work has mainly dealt with silicon nanocrystals and

aligned carbon nanotubes. She was the head of the Laboratory of Nanometric

Assemblies (LEDNA) in the fundamental research division of the Saclay CEA

center for 15 years. The LEDNA group follows the "bottom-up" approach of

nanosciences. It develops its own synthesis methods for the elaboration of

nano-objects and nanostructured materials with well-controlled characteristics.

The processes of their formation and the characterization of their properties,

especially those induced by size effects, are studied. The applications derived

from these activities are relevant for energy, health, environmental issues and

the development of composite materials. Another strong feature of the group is

the up-scaling of synthesis processes in order to favor industrial transfer.

cecile.reynaud@cea.fr