Page 12

Notes:

allied

academies

Journal of Industrial and Environmental Chemistry| Volume: 3

February 18-19, 2019 | Paris, France

Joint Event

Green Chemistry and Technology

8

th

World Congress on

International Conference on

Organic and Inorganic Chemistry

T

here is a need to develop sustainable and greener

processes in order to address excessive generation of

waste and recent advances in the field of biocatalysis is

making this possible. Biocatalysts in the form of enzymes

are environmentally-friendly, biodegradable, and adaptable,

enabling chemical transformations with remarkable regio-

and enantioselectivities. Protein engineering has enabled

the tailoring of enzymes to a required function and increased

catalytic efficiency, alter substrate recognition, and even

adding new structural functionality. The ability to implement

these engineered biocatalysts holds promise for sustainable

chemical manufacturing. However, several challenges remain

a barrier against a more widespread use of biocatalysis

including the cost of production of the biocatalyst itself

(difficulties in capturing and re-using the enzyme), as well

as the complexity of designing a manufacturing process. For

this, industry is looking at immobilisation as an opportunity.

Harnessing the synergy between biocatalysis and flow

chemistry, immobilisation onto a solid support makes it

possible to recycle the enzyme and, hence, reducing costs

associated with enzyme production. Immobilisation can

improve enzyme stability, prevent product contamination by

the enzyme reducing downstream processing requirements,

and facilitate the use of higher enzyme loadings for shorter

processing times. The EziG immobilisation platform is based

on polymer-coated controlled-porosity glass beads which

specifically anchor any protein containing a polyhistidine

(His6) tag. This platform offers a standardised solution

for targeted immobilisation of enzymes on a carrier.

These features of EziG enables biocatalysis to become an

accessible, effective, and sustainable choice for developing

greener processes.

Speaker Biography

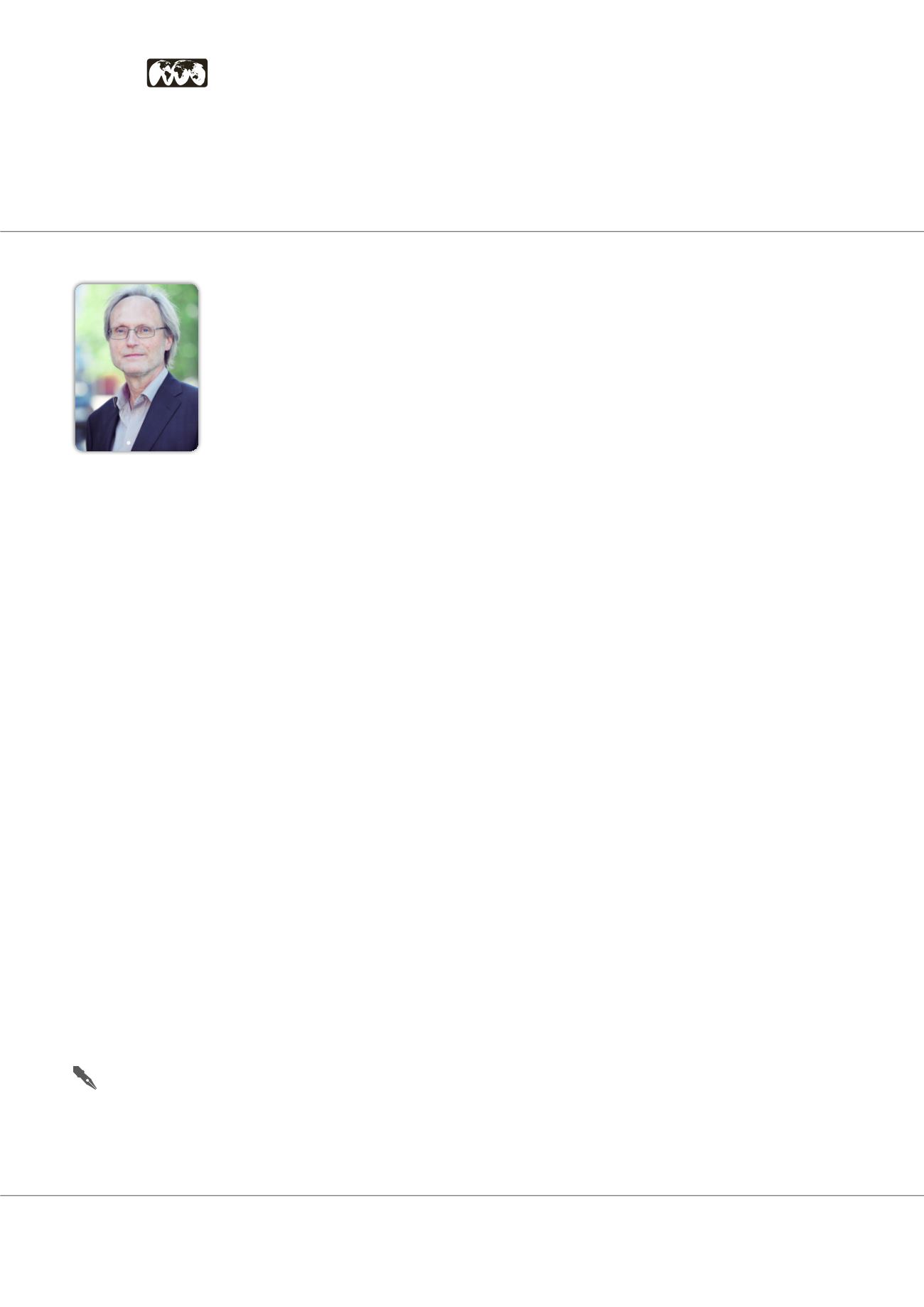

Hans Jurgen Federsel is a PhD in Organic Chemistry, Royal Institute of Technology

(KTH), Stockholm (1980). Starting as process R&D chemist in Astra, Sodertalje, Sweden

(1974) he has occupied positions both as line and project manager. After the formation

of AstraZeneca (1999) he became Director of Science, followed by appointment as

Senior Principal Scientist. Academic qualifications led to an Associate Professorship

(KTH,1990) and a seat on the Board of the School of Chemical Science and Engineering.

In 2009 he was elected to the Royal Swedish Academy of Engineering Sciences.

After closure of the R&D unit in Sodertalje (2012), he relocated to Macclesfield, UK

maintaining his previous role. In 2017 (February) he returned to Sweden, picking

up a role as Chief Scientific Officer in EnginZyme – a biotech company developing

a technology platform in biocatalysis, aimed at immobilization of enzymes. Since

1st January 2019, he has taken on the position as Vice President Science Relations.

e:

hans-jurgen@enginzyme.comHans Jurgen Federsel

EnginZyme, Sweden

Future of biocatalysis – Enzymatic reactions in continuous flow processes

Hans Jurgen Federsel, J Ind Environ Chem 2019, Volume 3

DOI: 10.4066/2591-7331-C1-007