Page 26

Notes:

Mater Sci Nanotechnol 2017 | Volume 1 Issue 2

allied

academies

Nanomaterials and Nanochemistry

November 29-30, 2017 | Atlanta, USA

International Conference on

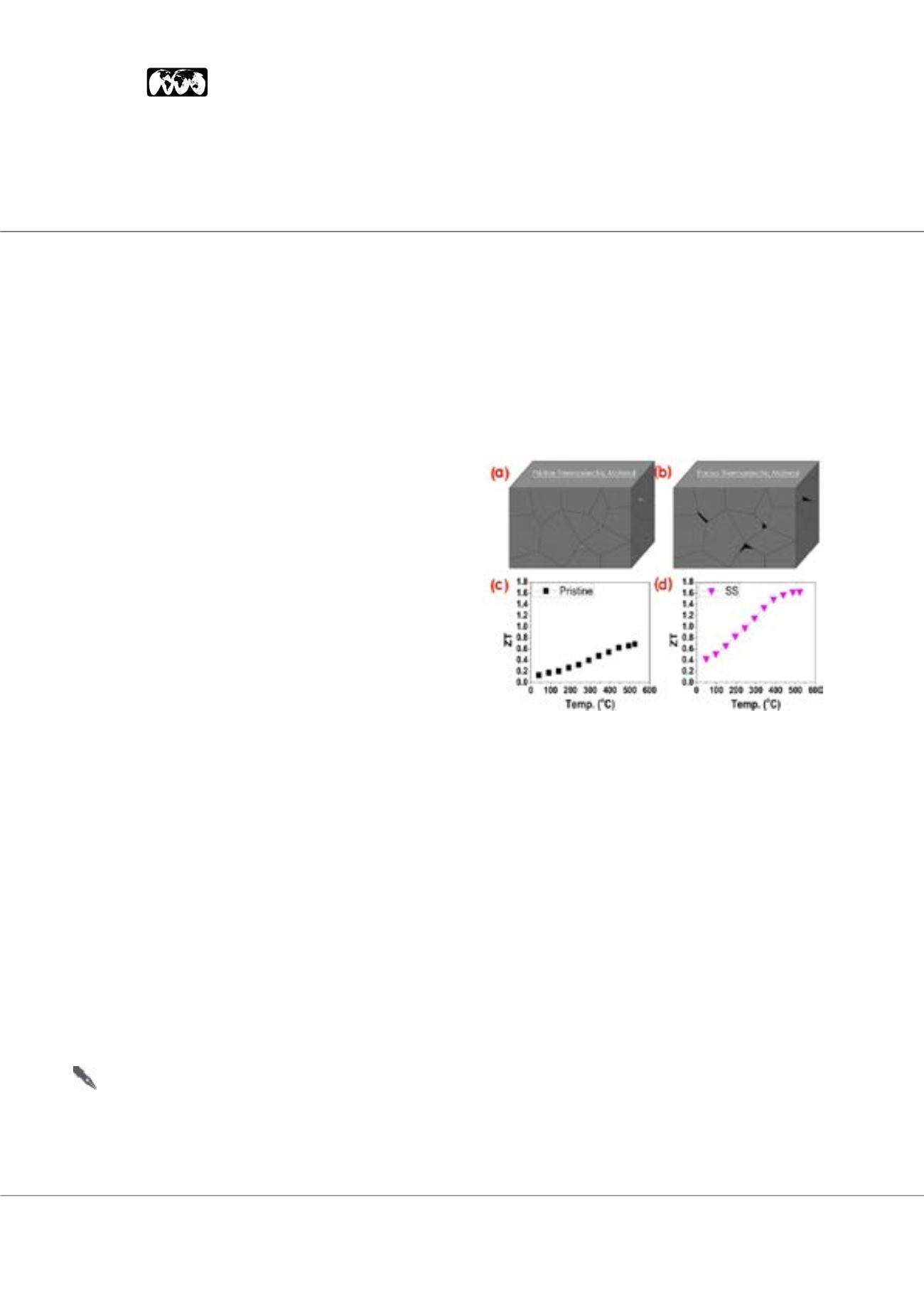

Nano-micro-porous skutterudites with 100% enhancement in ZT for high performance

thermoelectricity

Atta Ullah Khan

Rutgers University, USA

I

ncreasing energy demands require new materials, e.g.,

thermoelectrics, for efficient energy conversion of fossil fuels.

However, their low figure of merit (ZT) limits widespread

applications. Nanostructuring has been an effective way of

lowering the thermal conductivity. However, grain growth at

elevated temperature is still a big concern, for otherwise expected

to be long-lasting thermoelectric generators. Here, we report

a porous architecture containing nano- to micrometer size

irregularly shaped and randomly oriented pores, scattering a wide

spectrumof phonons without employing the conventional rattling

phenomenon. Lattice thermal conductivity reaches the phonon

glass limit. Basically, a low melting phase was sintering with

skutterudite powder. Later on, annealing under vacuum helped

this low melting phase evaporate from the structure, leaving

behind a mix of nano and micrometer sized pores. These pores

interact with phonons and causing them to either slows down

or dissipates, resulting in a very low thermal conductivity. On the

other hand, electrons can pass through the dense part due to their

ability to change path resulting in only a small drop in electrical

conductivity. This design yields greater than 100% enhancement

in ZT, as compared to the pristine sample. An unprecedented and

very promising ZT of 1.6 is obtained for Co23.4Sb69.1Si1.5Te6.0

alloy, by far the highest ZT ever reported for un-filled skutterudites,

with further benefits, i.e. rare-earth-free and improved oxidation

resistance enabling simple processing.

Speaker Biography

Atta Ullah Khan has his expertise in phase equilibria, crystallography, thermoelectric materials

and ceramics. He received his Ph.D in Physical Chemistry in 2011 from the University of Vienna,

Austria.Hehasworkedforthreeyearsasapostdoctoralfellow inNationalInstituteforMaterials

Science (NIMS), Japan. Currently, he is working as a Postdoctoral Fellow in Department of

Materials Science and Engineering, Rutgers, The State University of New Jersey, USA.

e:

atta.u.khan@rutgers.edu