Research Article - Journal of Food Science and Nutrition (2019) Volume 2, Issue 1

Study on the changes of sugar and acid in fermentation process of different varieties of cherry wine

Chaoshuang Jia1, Fengmin Han2, Xiaoyu Miao1, Aonan Yan1, Peng Wu2*, Yungang Sun3

1Key Laboratory of Food Processing Technology and Quality Control in Shandong Province, Grain Process Techno. Eng. Techno Center, College of Mechanical and Electircal Engineering, Shandong Agricultural University, Shandong Province, Taian 271018, Shandong Province, China

2College of Mechanical and Electrical Engineering, Shandong Agricultural University, Taian 271018, Shandong Province, China

3Shandong Institute of Pomology, Tai’an 271018, China

- *Corresponding Author:

- Peng Wu

College of Mechanical and Electrical Engineering

Shandong Agricultural University

Taian 271018, Shandong Province, China

Tel: 18854811635

E-mail: 1912363172@qq.com

Accepted Date: March 20, 2019

Citation: Jia C, Han F, Miao X, et al. Study on the changes of sugar and acid in fermentation process of different varieties of cherry wine. J Food Sci Nutr. 2019;2(1):15-19.

DOI: 10.35841/food-science.2.1.15-19

Visit for more related articles at Journal of Food Science and NutritionAbstract

This paper studied the changes of nutrients such as total sugars, total acids and pH values in the process of 7 sweet cherry and 5 sour cherry varieties. The results showed that the changed trends of total sugar contents of sour cherry varieties were basically the same. The sugar content decreases rapidly in the first 8 days of fermentation, and gradually stabilized in the later stage. The sugar content of “Meizao” and “Zaohongzhu” decreasesd rapidly, with a advantage of short brewing cycle compared with other sweet cherry varieties; While changing, the total acid content of sour cherry was significantly higher than that of sweet cherry, among which “Meizao” had the lowest acid content; The pH values of 12 kinds of cherries showed a tendency of decreasing in the early stage and increasing in the later stage. The pH value of “Meizao” was significantly higher than that of other cherry varieties during the brewing process, and the pH value of “Russian sour cherry” was the lowest. Although with different cherry varieties, the pH values in the brewing process were quite different, the final pH values were maintained between 3.6 and 4.5.

Keywords

Cherry wine, Fermentation, Sugar and acid, Change.

Introduction

In recent years, cherries (Cerasus pseudocerasus G.Don), as Rosaceae subgenus, are mainly distributed in places such as Shandong, Anhui, Henan and so on, and the main varieties include “red light”, “Meizao”, “black pearl”, “early-mahapphala”, “Rainey”, “pioneer” etc. [1]. In recent years, the cherry industry has developed rapidly and the yield has been increased rapidly. However, due to some limitations of cherries, such as difficult storage and transportation, short harvest period [2]. cherries are generally processed into juice, jam, dried fruit and cherry wine in addition to as fresh fruit. Among them, cherry wine not only prolongs its expiration date, but also greatly preserves the active ingredients of the fruit, thereby fully developing the cherry resources. In addition, cherry wine also has a very good health care effect, which is popular with the public [3,4].

Regarding the study of cherry wine, the predecessors mainly focus on the aspects of optimization of brewing process [5], yeast selection and identification [6], selection of brewing varieties [7], selection of clarifying agents [8], aroma [9] and so on, there are few studies studying changes of sugars and acids in the fermentation process of different varieties of cherry wine. Therefore, this study uses 12 cherry varieties as raw materials to study the change rules of main components such as total sugars, total acids and pH values in the fermentation process of different varieties of cherry wine, aiming at providing theoretical basis and technical guidance for the further processing of different varieties of cherries and the development of cherry wine, in order to promote the rapid development of cherry industry.

Materials and Methods

Materials and reagents

Cherry varieties for experiment: Rainier, Zaohongzhu, Tieton, Chelan, Black pearl, Red, Sir, Russian sour cherry, H-2, H-3, H-4, H-8, collecting fresh fruits in June 6, 2017, June 8, and June 14, 2017 respectively according to the ripening stage. The test materials were all taken from the Tianping Lake text base of Shandong fruit tree research institute, located on the daiyue bank of the balance in hubei district Tai’an City and the soil was hilly and mountains with poor soil quality. The institute built in 2010, with a plan spacing of 2.0 m × 4.5 m and looked like a spindle. Pure yeast: SIHA-Active-Yeast 3. White granulated sugar (Level 1): Shandong Dongdu Food co. LTD. Sulfur dioxide (Food Grade): Tianjin Chemical Plant. Dextrose: purity ≥ 99%. L(+) - Ascorbic Acid standard: purity ≥ 99%. Anhydrous ethanol, hydrochloric acid, Sodium acetate anhydrous, chloride of potash, citrate, sodium citrate, NaOH, metaphosphoric acid, oxalic acid, NaHCO3, 2,6-diohloroindophenol, CuSO4, methylene blue, sodium potassium tartrate tetrahydrate, zinc acetate, glacial acetic acid, potassium ferrocyanide, etc. were all analytically pure.

Instruments

UV-8000 uv-visible spectrophotometer: Shanghai Yuanxi Instrument Co. Ltd; TGL-20bR high speed desktop refrigerating centrifuge: Shanghai Anting Scientific Instrument Factory. Acidimeter: Hangzhou Huier Instrument Equipment Co. Ltd. HH-4 Numerical Show Constant Temperature Water Bath: Guohua Electric Appliance Co. Ltd. JA2003A electronic balance: Shanghai Jingtian Electronic Instrument Co. Ltd. SHB-III type multi- use of recycled water for vacuum pump: Zhengzhou Greatwall Scientific Industrial and Trade Co. Ltd. SB-1000 type water bath: Shanghai Ailong Instrument Co. Ltd. Kq-500de CNC ultrasonic cleaner: Kunshan Ultrasonic Instruments Co. Ltd. RE-52AA: Shanghai Yarong Biochemical Instrument Factory. Mill: Jiuyang JYZ-D51. LRH-150 Biochemical Constant Temperature Incubator: Beijing Zhongke Boda Co. Ltd. Distillation apparatus, alcohol meter: Shanghai Precision Instrumentation Co. Ltd.

Experimental method

Cherry → Sorting and Removing impurities → Cleaning, Removing the core → Beating → Cherry pulp → Enzymatic hydrolysis → Main fermentation (8 d, 20°C) → Postfermentation (20 d).

↑

White granulated sugar (16%) → Transferring → Ageing (4~8 months, 4°C) → Clarification,Filtration → Filling and Sealing → Finished product

Operation points: Select fresh and non-pest mature healthy cherry fruit, wash it with water, remove the cherry core with a core remover, and beat it with a beater. Add 2.5 L of cherry pulp into a 3 L glass jar with fermenting plug, then add 1.25 mL of meta-sulfuric acid solution, adjust the sugar content of the cherry pulp to 220 g/L with glucose, and add the activated yeast (weighed 0.5 g sugar first), after that, use the 10 ml 30°C water (not more than 40°C) to dissolve, add 0.2 g yeast, stir well). All the inoculum volume are 1 × 106 CFU/L, stand the middle product in 20°C biological tank to ferment. When the residual sugar content in the fermentation broth is ≤4.0 g/L, the fermentation is terminated by supplementing 0.5 mL of the metasulfuric acid solution. Afterwards, place the cherry wine in the 0~5°C atmosphere chamber for aging.

Analytical technologies

• Appraisal of fruit flavor and quality: 15 professional tasters were asked to evaluate different varietiesaccording to their taste, sour-sweet, sweet-sour, sweet [10].

• Determination of pH value of fruit: Weighed 5 g crashed cherry pulp, read it with the acidity meter, measured it 3 times in parallel, and the average value was calculated as the pH value [11,12].

• Determination of total sugar (in terms of glucose) of the fruit referenced GB 5009.8-2016.

• Determination of total acid of fruit referenced GB/T 12456-2008.

• Determination method of total sugar, total acid and pH value of cherry wine was carried out according to "General Analysis Method of Wine and Fruit Wine" (GB/T 15038-2006). Wherein, the total sugar was determined by direct determination with Ferien reagent, measured by glucose; the total acid was determined by sodium hydroxide titration, measured by malic acid; and the pH was measured by an acidity meter (Table 1).

Table 1. The Prunus pseudocerasus materials.

| Number | Variety denomination | Skin color | Flesh color | Flavor | Mature period | Harvest time |

|---|---|---|---|---|---|---|

| 1 | Rainier | Yellowish red | Faint yellow | Sour and sweet | Middle stage | 6th June |

| 2 | Zaohongzhu | Crimson | Red | Sweet | Middle stage | 8th June |

| 3 | Tieton | Crimson | Red | Sweet | Middle stage | 8th June |

| 4 | Chelan | Purple-black | Red | Sweet | Middle stage | 6th June |

| 5 | Black pearl | Purple-black | Purple-red | Sweet | Middle stage | 6th June |

| 6 | Red | Crimson | Red | Sweet | Middle stage | 6th June |

| 7 | Sir | Red | Red | Sour and sweet | Middle stage | 6th June |

| 8 | Russian sour cherry | Red | Red | Sour | Late | 8th June |

| 9 | H-2 sour cherry | Crimson | Red | Sour | Late | 14th June |

| 10 | H-3 sour cherry | Crimson | Red | Sour | Late | 14th June |

| 11 | H-4 sour cherry | Red | Red | Sour and sweet | Middle stage | 8th June |

| 12 | H-8 sour cherry | Crimson | Red | Sour and sweet | Late | 14th June |

Data processing

Origin software and SPSS 19.0 were used for statistical analysis, and Duncan's method was used to compare the mean values (P<0.05).

Results and Analysis

Comparative analysis of sugar and acid in different cherry varieties (Table 2).

Table 2. Change of sugar and organic acid.

| Number | Variety denomination | pH value | Total sugar (g/100 g) | Total sour (g/kg) |

|---|---|---|---|---|

| 1 | Rainier | 3.67 ± 0.0d | 9.32 ± 0.02g | 26.99 ± 0.2f |

| 2 | Zaohongzhu | 4.40 ± 0.06a | 8.50 ± 0.50h | 16.43 ± 0.18k |

| 3 | Meizao | 4.25 ± 0.03b | 10.27 ± 0.5e | 17.94 ± 0.15j |

| 4 | Chelan | 4.18 ± 0.0b | 11.94 ± 012b | 24.05 ± 0.27g |

| 5 | Black pearl | 4.36 ± 0.01a | 10.17 ± 0.21f | 149.27 ± 0.18i |

| 6 | Red | 4.24 ± 0.03b | 13.09 ± 0.09a | 17.93 ± 0.1j |

| 7 | Sir | 3.94 ± 0.04c | 10.35 ± 0.06d | 23.61 ± 0.21h |

| 8 | Russian sour cherry | 2.11 ± 0.03h | 7.00 ± 0.02L | 54.59v0.34c |

| 9 | H-2 | 2.21 ± 0.0g | 7.27 ± 0.06k | 87.81 ± 0.55a |

| 10 | H-3 | 2.17 ± 0.0g | 7.84 ± 0.09i | 51.30 ± 0.48d |

| 11 | H-4 | 3.44 ± 0.03e | 11.36 ± 0.11c | 40.54 ± 0.39e |

| 12 | H-8 | 2.28 ± 0.03f | 7.36 ± 0.05j | 76.58 ± 0.24b |

Note: different lowercase letters after the same column data indicate significant difference between materials (p<0.05).

The pH value

The pH value of different varieties ranged from 2.11 to 4.40, with an average of 3.44 and a coefficient of variation of 10.17%. SPSS analyzing the variance showed that there was difference in pH value between different varieties, and Zaohongzhu had the highest content, at 4.40, which was significantly different from other cherries (P<0.05). 'Russian sour cherries' had the lowest pH, at 2.11. The cherries with higher pH values included 'Black pearl', 'Meizao', 'Red' and 'Chelan', etc. H-3 ', 'H-2' and 'H-8' had lower pH values.

Total sugar

The content of total sugar in different varieties ranged from 7.00 to 13.09 g/100 g, with a mean of 9.54 g/100 g and the coefficient variation was 19.18%. Shown by the variance of SPSS, there was a difference in total sugar content among different varieties. The content of 'Red' cherries was the highest at 13.09 g/100 g, which was significantly different from other cherries (P<0.05). The content of 'Russian sour cherry' was the lowest at 7.00 g/100 g. Cherries with higher content of total sugar include 'Red', 'Chelan', 'H-4' and 'Sir', etc. The lower content was 'H-2', 'H-8' and 'H-3'.

Total acid

The total acid content of different varieties ranged from 16.43 to 87.81 g/kg, with a mean of 38.09 g/kg and coefficient variation of 9.43%. There was a difference in total acid content among different varieties by variance of SPSS. The content of 'H-2' was the highest at 87.81 g/kg, which was significantly different from other cherries (P<0.05). Zaohongzhu was the lowest, at 16.43 g/kg. The cherries with higher total acid include 'H-8', 'Russian sour cherry' and 'H-3', etc. 'Red', 'Tieton', 'Black pearl' had lower content.

Changes in saccharic acid during cherry fermentation

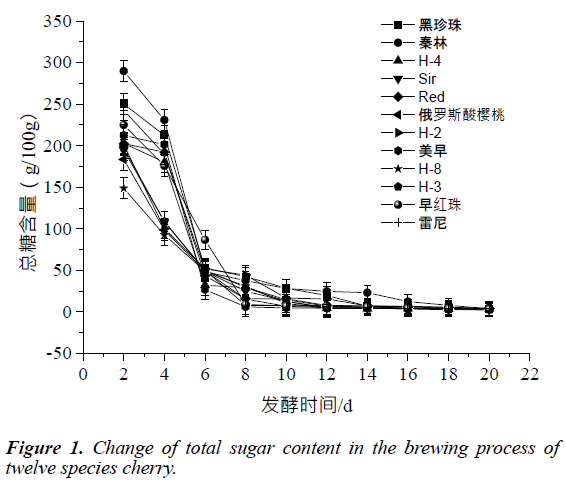

Changes of total sugar: It can be seen from Figure 1 that the total sugar content of the 12 varieties of cherries during the fermentation process shows a rapid decrease in the early stage and a stable stability in the later stage. Chiefly because growth and metabolism of yeast were flourishing in fermentation prophase, much sugar was consumed and almost run out in fermentation anaphase. The changes of total sugar content of 12 cherries in the fermentation process were significantly different. The changed trends of total sugar content of 'Russian sour cherry', 'Sir', 'H-3', 'H-2' and 'H-8' were basically consistent which decreased rapidly in the first 8 days of fermentation and gradually stabilized in the later stage; the total sugar content of ‘Zaohongzhu’ plummeted in the first 8 days of fermentation and then tended to be flat. The changed trends of cherry total sugar content of the remaining 6 kinds were basically consistent and the speed of the 6th day was higher than that in the 4th day during the fermenting period. It may be the restriction of varieties that slowed down the multiplication rate of yeast and made the quantity remain low. The sugar content of ‘Tieton’ and ‘Zaohongzhu’ decreased below 10 g/100 g on the 8th day of fermentation and tended to stabilize in the later, which showed that these two had the advantage of shorter brewing period than others. By observation, on the fourth day, there were bubbles in the upper layer but the lower layer was clam; on the 6th day, the production of bubbles increased and the reaction became intense, at this time, the number of yeast increased logarithmic, which converted sugar into alcohol and carbon dioxide (J. White B et al., 2013), and the sugar content declined rapidly. In the post-fermentation stage, the sugar content was still decreasing, until 16 days later, the amount of sugar available to yeast was reduced, and the content of alcohol also had a certain impact on the vitality of yeast. All the changes in the sugar content of 12 kinds of cherry wine tended to be stable.

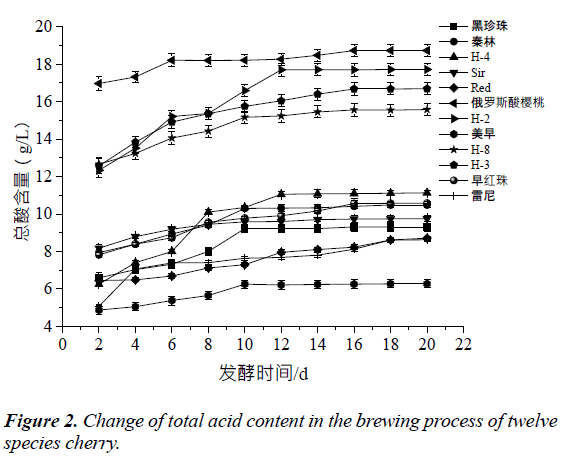

Changes of total acid content: It can be seen from Figure 2 that the total acid content of all 12 varieties during the fermentation process shows a relatively fast growth in the early stage and a stable stability in the later stage. The total acid content of 'Russian sour cherry' showed an upward trend in the first 6 days of fermentation, and then maintained at a relatively stable level; the total acid content of 'Sir' showed an upward trend in the first 8 days of fermentation and then maintained at a stable level. The total acid content of 'H-8', 'Chelan', 'Black pearl' and 'Meizao' showed an upward trend in the first 10 days of fermentation, and then maintained at a stable level; the total acid content of 'H-2' and 'H-4' showed an upward trend in the first 12 days of fermentation, and then maintained at a stable level. The total acid content of 'H-3' and 'Zaohongzhu' showed an upward trend in the first 16 days of fermentation and then maintained at a stable level; the total acid content of 'Red' and 'Rainier' showed an upward trend in the first 18 days of fermentation, and then maintained at a stable level. Among them, the total acid content of ‘Russian sour cherry’,‘H-2’、‘H-3’、‘H-8’ was significantly higher than that of other 8 kinds of cherries, of which 'Meizao' had the lowest acid content and 'Meizao' had the lowest acid content. It may be because the acid content of sour cherry itself was higher than that of sweet cherry, which provided a theoretical basis for proper control of acid content in the selection of late wine varieties [13,14]. According to the theory of yeast fermentation, yeast cells will eventually degrade glucose to pyruvic acid through the glycolysis process and pyruvic acid is reduced to alcohol under non-oxidative conditions; and during the process of fermentation, glucose also undergo other methods such as sugar degradation to produce some organic acids [15]. Such as citric acid and lactic acid. Therefore, during the fermentation of cherry wine, the total acid content gradually increased, as the fermentation time prolonged, the sugars in the fermentation broth were almost completely decomposed and the acidity was maintained stable.

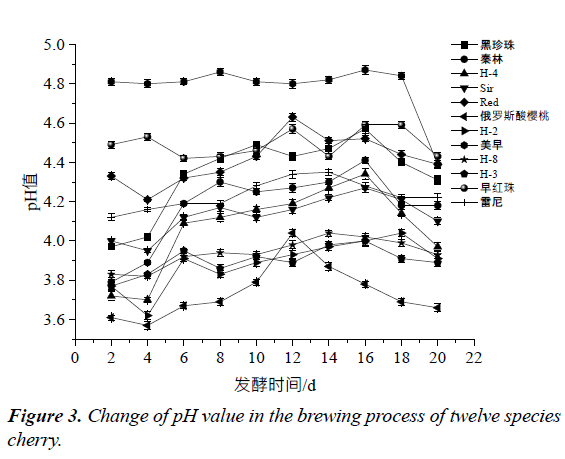

Changes of pH value: During the brewing process of cherry wine, many biochemical reactions are related to pH, and the change in pH is closely related to the quality of cherry wine. When the pH value is too high, the stability of cherry wine will be poor which will affects the quality of cherry wine, so controlling its pH value during brewing is one of the key links [16,17]. It can be seen from Figure 3 that the pH values of the 12 kinds of cherries in the fermentation process shows a trend of decreasing in the early stage and increasing in the later stage. The pH values of different cherry varieties during the winemaking process are significantly different, and there are some differences in the extent of increase and decrease. It is helpful to control the PH value of different kinds of cherry wine in the later stage. The pH value of 'Mei Zao' was significantly higher than that of other cherry varieties during the brewing process. The pH value remained stable in the early stage and decreased rapidly after the 18th day. The pH value of 'Russian cherry' was the lowest and increased gradually in the early stage of fermentation while dropped rapidly after 12th day. The increase in pH was due to the rapid growth of yeast to produce alcohol, which inhibited the invasion, growth and acid production of harmful microorganisms, but after entering the middle stage of fermentation, various microorganisms rapidly grew and produced lactic acid and lactobacillus, a small amount of carbon dioxide lowered the pH [18-21]. Although the cherry varieties were different and the pH values were greatly different during the brewing process, the final pH values were maintained between 3.6 and 4.5.

Conclusions

By analyzing the main components of 12 cherry varieties, the highest pH value was' Zaohongzhu' (4.40), and the lowest was' Russian sour cherry ' (2.11), which indicated that the pH value of sweet cherry varieties was generally around 3~4 while the sour cherry was generally concentrated around 2~3. The highest content of total sugar was "Red", respectively at 13.09 g/100 g and 12.75 g/100 g, which was significantly different from other kinds of cherries (p<0.05). The lowest content of total sugar was "Russian sour Cherry" (7.00 g/100 g). The highest total acid content was' H-2 ' (87.81 g/kg), and the 'Early Red Pearl' content was the lowest, which was 16.43 g/kg. The acid content of the sour cherry varieties was significantly higher than that of sweet cherry varieties.

The changed trend of total sugar content of sour cherry varieties was basically consistent that the sugar content decreased rapidly in the first 8 of fermentation and gradually stabilized in the later stage. The sugar content of "Mei Zao" and "Zao Hongzhu" decreased rapidly compared with other sweet cherry varieties, which had the advantage of short brewing cycle. In the changes of total acid content, the total acid content of sour cherries was significantly higher than sweet ones, "Mei Zao" had the lowest acid content among them; During the fermentation, pH values of all 12 kinds of cherries showed a similar tendency that increasing in the early stage and decreasing in the later stage. The pH value of 'Tieton' was significantly higher than others, and the pH value of 'Russian sour cherries' was the lowest. Although there were significant differences in pH values of different cherry varieties during fermentation, final pH values were maintained between 3.6 and 4.5. It can be seen that different cherry varieties have significant differences in pH value during fermentation and the increase and decrease of pH value has certain differences, which has certain guidance for controlling the pH value of different cherry wines in the later stage.

References

- Cao J, Jiang Q, Lin J, et al. Physicochemical characterisation of four cherry species (prunus spp.) grown in china. Food Chemistry. 2015;173:855-63.

- Blando F, Gerardi C, Nicoletti AI. Sour Cherry (Prunus cerasus L) Anthocyanins as Ingredients for Functional Foods. Biomed Research International. 2007;2004(5):253-8.

- Hassan Omran S, Dragana Dabić C, Maja Natić M. Chemical profile of major taste and health related compounds of Oblačinska sour cherry. Journal of the Science of Food and Agriculture. 2016;96(4):1241-51.

- Cásedas G, Francisco L, Gómez-Serranillos Maria Pilar,Smith Carine,López Víctor(2016). Bioactive and functional properties of sour cherry juice (Prunus cerasus). Food & function. 2016;7(11):4675-82.

- Coelho E, Vilanova M, Genisheva Z, et al. Systematic approach for the development of fruit wines from industrially processed fruit concentrates, including optimization of fermentation parameters, chemical characterization and sensory evaluation. LWT - Food Science and Technology. 2015;62:1043-52.

- Xu Cheng, Wang Jing, Sun Yanyan, et al. Screening and identification of yeast used for cherry wine. Food Science and Technology. 2017;11:14-8.

- Miličevic B, Babic J, Šubaric D, et al. The effects of the fermentation with immobilized yeast and different cherry varieties on the quality of cherry brandy. Croatian Journal of Food Science & Technology. 2014;6:104-9.

- Soleas GJ, Goldberg DM. Potential role of clarifying agents in the removal of pesticide residues during wine production and their effects upon wine quality. Journal of Wine Research. 2000;11:19-34.

- Fairbairn SC, Smit AY, Jacobson D, et al. Environmental stress and aroma production during wine fermentation. South African Journal for Enology & Viticulture. 2014;35:168-77.

- Zuobing X, Xuan Z, Yunwei N, et al. Gc-o combined with OAV to analyze characteristic aromatic components of cherry wine. Chinese journal of food science. 2017;17:246-54.

- Rada-Mendoza M, Olano A, Villamiel M. Determination of hydroxymethylfurfural in commercial jams and in fruit-based infant foods. Food Chemistry. 2003;79(4):513-6.

- White J, Munns DJ. Influence of temperature on yeast growth and fermentation. Journal of the Institute of Brewing. 2013;57(4):280-4.

- Usenik V, Fabcic J, Stampar F. Sugars, organic acids, phenolic composition and antioxidant activity of sweet cherry (prunus avium l.). Food Chemistry. 2008;107:185-92.

- Khoo GM, Clausen MR, Pedersen BH, et al. Bioactivity and total phenolic content of 34 sour cherry cultivars. Journal of Food Composition & Analysis. 2011;24:772-66.

- Pham T, Wimalasena T, Box WG, et al. Evaluation of its pcr and rflp for differentiation and identification of brewing yeast and brewery ‘wild’ yeast contaminants. Journal of the Institute of Brewing.2012;117(4):556-68.

- Boulton R. The general relationship between potassium, sodium and ph in grape juice and wine. American Journal of Enology & Viticulture. 198;31(2):182-6.

- Walker RR, Blackmore DH. Potassium concentration and ph inter‐relationships in grape juice and wine of chardonnay and shiraz from a range of rootstocks in different environments. Australian Journal of Grape & Wine Research. 2012;18:183-93.

- Volschenk H, Vuuren HMV, Viljoenbloom M. Malic acid in wine: origin, function and metabolism during vinification. South African Journal of Enology & Viticulture. 2006;27(2):123-36.

- Fleet GH. Growth of yeasts during wine fermentations. Journal of Wine Research. 1990;1(3):211-23.

- Mills DA, Phister T, Neeley E (2008) Wine Fermentation. Molecular Techniques in the Microbial Ecology of Fermented Foods.

- Nicomrat D, Chamutpong S. Diversified microbial community developed in different fruit juice of wine fermentation. Applied Mechanics & Materials. 2017;866:57-60.