Research Article - Journal of Food Technology and Preservation (2017) Volume 1, Issue 1

Recent advances in conventional drying of foods

Daniel Maisnam1, Prasad Rasane1,2*, Anirban Dey1, Sawinder Kaur1, Chayanika Sarma11Department of Food Technology and Nutrition, Lovely Professional University, Jalandhar 144411, Punjab, India

2Centre of Food Science and Technology, Banaras Hindu University, Varanasi 221005 Uttar Pradesh, India

- *Corresponding Author:

- Prasad Rasane

Food Technology and Nutrition

Lovely professional University

India

Tel: +91 918968976119

E-mail: rasaneprasad@gmail.com

Accepted date: February 23, 2017

Citation: Maisnam D, Rasane P, Dey A, et al. Recent advances in conventional drying of foods. J Food Technol Pres. 2017;1:25-34

Abstract

Drying of food is perhaps the oldest method of food preservation. Conventional drying technologies have now been used on commercial scale for drying numerous food products. Different methods of drying are associated with advantages and limitations. Natural and artificial methods have been employed to preserve valuable commodities. The major concern with drying using artificial dryer is that it is energy intensive even though drying time is shorter as compared to the natural method of drying. Drying kinetics has been studied to predict drying time and conditions for several food products. The review aims at displaying evolution of these techniques and critically reviewing the challenges and opportunities for drying of foods.

Keywords

Artificial drying, Drying, Drying kinetics, Dried food products, Natural drying.

Introduction

Drying is the process wherein moisture is removed from the food material as a result of concurrent heat and mass transfer [1]. Heat is applied through conduction, convection and radiation to force water to vaporises, whilst removal of vapours is achieved by employing forced air. Foods such as fruits and vegetables have a high moisture content of more than 80% which makes them highly susceptible to spoilage causing bacteria. Dehydration preserves food in a stable and safe condition by reducing water activity, extending the shelf life much longer than that of fresh produce [2]. Considering the perishable nature of fruits and vegetables it is necessary to preserve them and drying is one such method to do it especially in developing countries like India where cold storage facilities are poorly established. The conventional method of drying includes vacuum drying, solar drying [3], air drying [4], fluidized bed drying [5], spouted bed drying [6], and freeze-drying [7]. Drying kinetics of apple [8], black carrot [9], strawberries [10], carrot [11], garlic [12], guava [3], papaya [4], jackfruit [13], sweet potato [14], banana [15] and mushroom [16] have been successfully studied. Understanding drying kinetics is important to choose the method of and to control the process of drying.

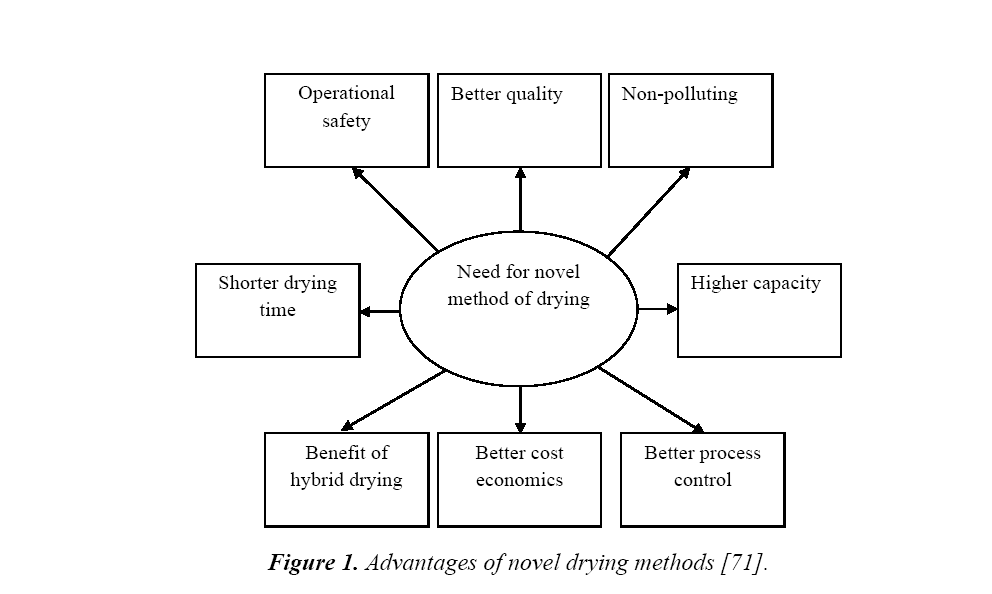

Conventional methods rely on conductive and convective methods for heat transfer but these methods causes the end product to have a poor quality and high possibility of contamination. This leads to the development of dryers that have the capacity for more efficient and reliable drying techniques such as explosion puff drying [8], combined microwavevacuum drying [10], infrared drying [17] and ultrasound freeze drying [18]. Technique such as vacuum drying removes the air and preserves properties such as texture, colour, taste and flavour of dried products. In vacuum the water present in the fruits and vegetables gets evaporated quickly and at a lower temperature as compared to the atmospheric temperature this results in less damage because the food is not exposed to a high temperature and in the absence of air oxidation reaction does not occur [16]. Hence, such technique can be employed to preserve the desirable properties of dried foods. The advantages of novel methods of drying are illustrated in Figure 1. The aim of this paper is to compare the efficiency of different drying methods and to discuss the various methods of drying with respect to the retention and preservation of nutrient content, texture, colour, taste, flavour and other desirable properties of food. The effect of various physical and thermodynamic properties of food on the drying kinetics will also be discussed.

Drying methodology

Drying methods can be broadly classified into natural and artificial methods of drying. The natural method of drying utilizes the solar energy to remove the moisture content in the food, with a disadvantage of dependence on weather condition and poor operational performance [19]. Artificial methods of drying have advantages over natural method of drying. According to Okora and Madueme [20], artificial methods have the capacity to remove large amount of moisture efficiently. In addition to this controlling various factors involved such as temperature, drying air flux and time of drying is also possible. Artificial drying is done with the help of mechanical or electrical equipment.

Natural drying methods

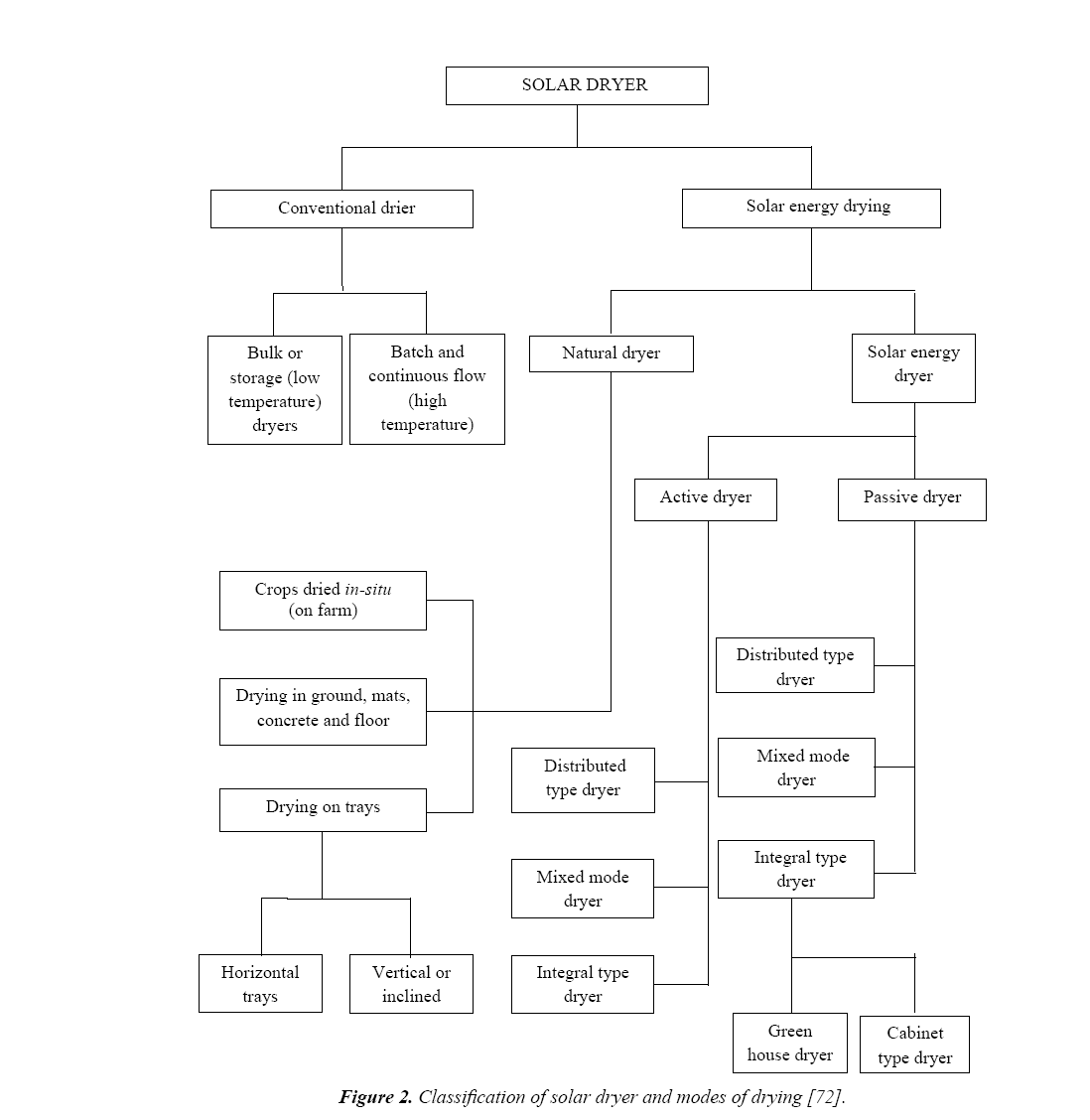

Solar drying; Sun is an inexhaustible and free source of energy, utilized for drying of foods since ancient times. Solar drying can be classified into direct and indirect method of drying.

Direct method: In open sun drying the food to be dried is left exposed to the sun for a number of days to achieve the desired moisture content. In developing countries where fuel is scarcely available to farmers due to high cost, open sun drying is the most popularly used method of drying since it is simple and only requires sunlight [21]. Insect infestation, dust and dirt contamination, long time for drying, over heating due to direct exposure, quality deterioration and low rate of transmission of heat due to condensation of the evaporated moisture are some the major problem faced during open air drying [1]. The simplest form of solar dryer consisted only a wooden box and metal sheets of the dimensions 2m x 1m. It consisted of air holes and polyethylene sheets to cover the upper surface of the food material to be dried [22]. Kumar and Sagar [3] successfully experimented drying of mango, guava and anola using a direct type solar dryer. The methods and modes used in solar drying are illustrated in Figure 2.

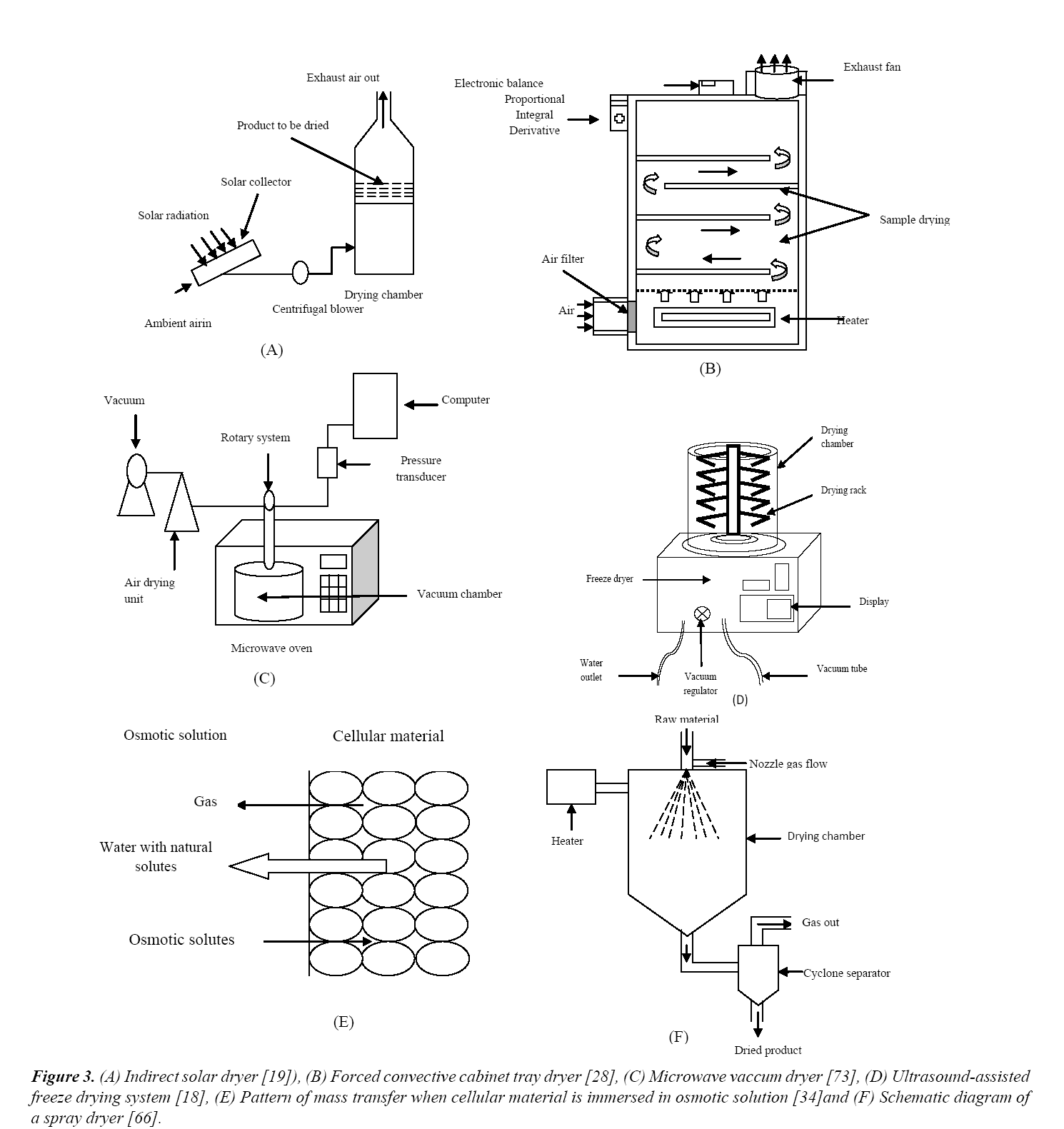

Indirect method: Indirect solar dryer have been developed to overcome the problems encountered by the direct method of drying. Chamber type, chimney type, and wind-ventilated dryers are classified as indirect solar dryers. In the indirect method of solar drying, the heat acquired by the system is used to heat the air that flows through the product to be dried. The top of the drying chamber is vented to remove the moisture due to evaporation [19]. An indirect solar dryer based on the principle of psychometric was developed to dry mangoes [23]. The dryer had a composite absorber system and consisted of flat plate absorbers, glass cover, wire mash, absorber glass, chimneys and drying chambers. Upon drying of fresh samples of mangoes the temperature of the drying air rises to 40°C during afternoon and the thermal efficiency of the flat plate collector and wire mesh were found to be roughly 17 and 12% respectively. A mathematical model of thin layer drying of strawberries using the indirect forced convection solar dryer was developed by El - Beltagi et al. [24]. It consists of a drying chamber and Wcorrugated black aluminium sheet solar collector for maximum absorption of solar radiation, a glass cover of 4 mm thickness was placed on top of the W-corrugated sheet to minimize the heat dissipation. The whole set up was tilted as horizontal plane and surrounding air was drawn in with the help of a fan and then heated up in the solar collector which then enters the drying chamber in a bottom to the top flowing action through the food to be dried. An indirect solar dryer is illustrated in Figure 3A.

Figure 3: (A) Indirect solar dryer [19]), (B) Forced convective cabinet tray dryer [28], (C) Microwave vaccum dryer [73], (D) Ultrasound-assisted freeze drying system [18], (E) Pattern of mass transfer when cellular material is immersed in osmotic solution [34]and (F) Schematic diagram of a spray dryer [66].

Artificial drying methods

Convective drying: Convective method of drying is employed to remove water from the food substances through the application of heat in equipment meant for drying. Hot air is allowed to pass through the product in a manner to transfer the heat to the food and moisture is removed [25].

In the drying of strawberries in an experimental hot air tunnel dryer with an air flow of 1 m/s parallel to the sample at different temperatures of 60, 70, 80 and 90°C showed a decrease in the anthocyanin content and antioxidant capacity. It was also observed that there was no change in the area, parameter and feret diameter when dried at 70 to 90°C. However, drying at 60°C decreased the area, perimeter, feret diameter and the fractal dimensions of the parenchymal tissue of the strawberries [26]. A convective tray dryer is illustrated in Figure 3B. A study was carried out to know the effects of alkaline ethyl oleate pre-treatment on oven drying of strawberries. The drying temperatures were 50, 55 and 65°C with an air velocity of 1.2 m/s [27]. It was observed that the pre-treated strawberries had a higher drying rate and decreased drying time. The pre-treated samples also had better rehydrating properties as compared to the sample which had not been pre-treated. Combination of osmotic and convective drying method was studied on many fruits and vegetables such as mango [3], mushrooms [16], ginger [28], jack fruit [29], button mushroom [30] and grapes [31].

Drying by radiation: Long drying time and high temperature are the factors responsible for the loss of heat sensitive components of the food. Microwave radiation is an electromagnetic radiation which works in between the frequency range of 300 MHz to 300 GHz and have a wave length of 1mm to1m. The propagation of microwave through space is by means of electric and magnetic field. Microwave heating is beneficial as it requires lesser amounts of time and temperature to remove the moisture content in foods [6]. Scorching is a problem in microwave heating because of the low availability of water content towards the end of the drying process. The major advantage of using microwave is its ability to be combined with other method of drying such as vacuum drying [10]. Button mushroom were prepared using microwave-vacuum drying [16]. The power of the microwave was in the range of 115 to 285W and a pressure range of 6.523.5 KPa, the mushroom was sliced to a thickness of 614 mm. They observed that microwave drying takes 70 to 90% shorter drying time retains better rehydrating properties as compared to the convective air drying method. A vacuumed microwave dryer is illustrated in Figure 3C. Infra-red heating is another method of removal of moisture from foods. According to Askari et al. [6], infra- red have a wavelength range of 0.75 and 1000 μm. Exposure of food to infra-red led to charge build up in the electronic state as well as in the vibrational and rotational state at the atomic and molecular levels. This caused the food to heat up without any changes in the temperature of the air surrounding the food. Infra-red drying has been used to dry various agricultural commodities including carrot [11], sweet potato [14], and tomato [17].

Freeze drying; Freeze drying is the process of drying a substance through freezing and removal of solvents associated with direct sublimation. Unavailability of liquid water during freezing and low temperature results in the production of a superior quality end product and most of the reactions involving the microbes are completely stopped [32]. About 90% of the water present in the fruits is removed in the first phase of freeze drying. One important characteristic of freeze dried fruits is the ability of the fruits to rehydrate, Differences in the rehydration property of freeze dried fruits is due to salt concentration, desorption of water, break down of pectin cells in the membrane, size of water crystal and its porosity. The rehydration property of the freeze dried product is rapid and the organoleptic property of the rehydrated foods is almost similar to the fresh product. Minimum volume reduction, minute chemical change, minimum loss of volatile components, long storage period, stability, ability to be used as an antioxidants and colorants are the advantages of freeze dried products [7]. The disadvantage of the freeze dried products includes high cost and energy consumed during the freezing, drying and condensing process. Due to the high freeze drying time, collapse of the product can happen which may result in loss of aroma and yield tough product with low rehydration capacities [33]. An integrated ultrasound freeze drying system was developed to dry bell pepper by Schossler et al. [18]. Continuous application of ultrasound at 6.5 μm was found to have an immediate heating effect on the sample at reduced ambient pressure. The application of ultra sound was found to reduce the drying time by 11.5%. The dryer developed is illustrated in Figure 3D.

Osmotic drying: In osmotic drying, foods to be dried is placed in a hypertonic solution which causes a difference in concentration and causes the water content of foods to be driven out from the sample to the solution. Diffusion of the solutes from the solution into the tissue of the fruits and vegetables also takes place [30]. The transfer of mass during osmosis may be responsible for the change in physical, chemical, nutritional values, taste and structural properties of the final product [32,34]. The mechanism of osmotic dehydration is illustrated in Figure 3E. Monosaccharides, disaccharides and salts such as sodium chloride are the most commonly used osmotic ally active solutes. The possibility of the process to be conducted at room temperature makes it more advantageous than other conventional method of drying such as hot air or vacuum method of drying since energy required for carrying out the procedure is significantly less [35]. Alam et al. [36] investigated the osmotic drying of anola and studied its effect on its quality. Sugar concentration of 50-70°Brix, solution temperature of 30 to 60°C and time of treatment of 60 to 180°C was used in the study. It was found that a sugar concentration of 59°Brix, solution temperature of 51°C and an immersion ratio of 60 min was found to be the most effective treatments. Similar experiment was also conducted by [30] in osmotic dehydration of button mushroom. According to Kumar and sagar [3], a combination of osmotic treatment and vacuum drying is more effective in drying anola. Osmo-vacuum dried anola showed higher amount of sugar than fresh anola, similar result were also obtained when mango and guava was osmovacuum dried.

Drying kinetics and modelling

Studying drying kinetics is a means to choose appropriate drying methods and to control the processes of drying. It is also important for engineering and process optimization. It is sometime expensive to conduct a full scale experiment to determine the suitable condition for drying. Drying kinetics is used to express the moisture removal process and its relation to the process variables and hence, a good understanding of the drying rate is important to develop a drying model [37]. According to Khazae and Daneshmandi [38] the thin layer drying models can be classified into three categories viz. theoretical, semi theoretical and empirical. Theoretical models only consider the internal resistance in transfer of moisture, however, the semi theoretical and empirical models only consider the external resistance in the transfer of moisture between air and product [39]. Empirical models fails to take into account the fundamentals of drying process and is able to explain only the drying curve for drying condition but not the processes that occurs during drying [40]. Semi theoretical model of drying includes: Lewis models, Handerson and Pabis model, Logarithmic model and Page model etc. Fick’s second law of diffusion is the mostly commonly used theoretical model. Theoretical models are inadequate and tend to generate erroneous results and are complex for practical applications. Hence, semi theoretical models have been developed to ease the use and to fit the drying data of the food material to be dried [41]. The Handerson and Pabis model, firstly used for model drying of corn is the first term of general series solution to Fick’s law. However, due to inaccuracy and high degree of temperature difference between kernel and air, the model could not be fitted during the first 1 or 2 hour of drying corn [42]. The first two terms of general series solution to Fick’s second law is the two term model. The two term model however, does not consider the shape of the product dried. The model assumes constant diffusivity and requires the temperature of the product to be constant. It has been fitted in the drying of kenaf [43] and corn [39]. Lewis model is a special case of Handerson and Pabis model. According to Bruce [44] the model is inaccurate; it overestimates the first period and underestimates the last period of drying. Semi theoretical models are the simplified general series solutions of the Fick’s second law. These models, however works only when temperature, relative humidity, air velocity and moisture are in the range at which the models are developed. Time requirement is less and shapes of the material dried are not considered in semi theoretical models [45]. Drying kinetics models does not take into account the effects of interactions by parameters other than the time of drying. Models that incorporate a large number of variables still do not exist but due to the complex non-linear relationship between the kinetics of drying and variables related, the development of such models is not feasible [38]. A list of models used in drying kinetics is given in Table 1.

Table 1. Mathematical models used in drying kinetics.

Models for drying |

Formulas | Reference |

|---|---|---|

| Two term | MR=a exp(-k0t)+b exp(-k1t) | [39] |

| Simplified Fick’s Diffusion equation | MR=a exp[-c(t/L2)] | [41] |

| Handerson and Pabis | MR=a exp(-kt) | [42] |

| Modified page II | MR=exp(exp(-c(t/L2)n) | [67] |

| Lewis model | MR=exp(-kt) | [44] |

| Simplified Flick’s diffusion | MR=a exp(-c(t/L2)) | [67] |

| Page model | MR=exp(-ktn) | [69] |

| Modified page | MR=exp[-(kt)n] | [70] |

t: Drying time (s); a, b, c, g,n: dimensionless constant for drying; k, k1, k0: Drying velocity constant; exp: experimental; MR: Moisture Ratio; L: thickness of the material; R: Correlation coefficient.

Effect of air temperature and air velocity on drying kinetics: Air temperature is one of the prime factors influencing the drying kinetics during dehydration. Drying constant, equilibrium moisture content and moisture diffusivity increases as the temperature increases [46]. In the study conducted by Abano et al. [47] effects of air temperature on the drying kinetics of tomato slice were evaluated. Three empirical models namely Page, Logarithmic and Henderson and Pabis model were fitted to explain the drying kinetics. Air temperature of 50, 60, 70 and 80°C were used for drying. Constant rate of drying period was observed when tomato slices were dried at 50 and 60°C. However, inconsistency was observed when dried at 70 and 80°C which indicate the importance of diffusion as a governing physical mechanism for moisture removal. Krokida et al. [46] studied the effects of sample size and the conditions of air on the drying kinetics of horticultural produce such as potato, carrot, pepper, garlic, mushroom, onion, leek, pea, corn, celery, pumpkin and tomato. In the study the first order drying kinetics predicted the drying kinetics of the samples at two ambient (30°C) and elevated temperatures (70°C). Increase in temperature of the air resulted in the increased loss of moisture and decrement in the moisture equilibrium of the sample. In the experiment conducted by Tzempelikos et al. [48] the time of drying quinces was found to be influenced by the air temperatures and air velocities used for drying. Drying time was reduced by 30% with increase in the air velocity at a temperature of 60°C while 54% reduction in drying time was observed when temperature was increased from 40 to 60°C at an air velocity of 2 m/s.

Effect of shape on drying kinetics: Borges et al. [15] studied the influence of shape on the drying kinetics of banana. The species of banana used in the experiment were Prata and Dagua banana. The banana was cut into disk and cylindrical shapes and dried in a tray drier at a temperature of 40 and 70°C. The drying rate was significantly higher with disk shaped Dagua banana as compared to the cylindrical shaped banana. Positive influence of temperature on Parta banana was also observed. Effect of blanching could only be observed in case of Parta banana when dried at 40°C. Bakal et al. [49] studied the effect of size of sample during the fluidized bed drying of potato. The potatoes were cut into cubical and cylindrical shapes and dried at a temperature of 50, 60 and 70°C and air velocity of 7 m/s. It was found that the diffusion coefficient was positively influenced by the thickness of the sample. The drying constant increased with the increment in the aspect ratio and the diameter to length ratio due to the increase in surface area. Naderinezhad et al. [50] studied effect of air temperature, air velocity and sample shape (circle and square) on drying potato slice. As compared to shape the air velocity and air temperature were found to have a more profound effect on the drying time. It was also observed that the drying square slice was lower as compared with the cylindrical samples.

Effect of pre-treatment: Most food products are pre-treated before drying to shorten the drying time, improve taste, structure, to conserve the flavours and to maintain the nutrition of the food. Pre-treatment reduces the initial water content and modify the tissue of the food material which helps to fasten the drying rate [8]. The influence of blanching was studied by Doymaz [27] on the drying kinetics of leek slice. Pealed leeks slice were blanched for 3 min in hot water of 70°C. The drying rate and rehydration properties of blanched sample were found to be improved as compared with the unbalanced sample. The influence of pre-treatment on the drying kinetics of seedless grapes was carried out by Bai et al. [51] using the novel method of high humidity hot air impingement blanching (HHAIB) pre-treatment. This method not only reduces the drying time but also produced a desirable end product due to inhibition of enzymatic browning. Romero et al. [52] studied the effect of ultrasound pre-treatment on the drying kinetics of the andean blackberry (Rubus glausus Benth) using Fick’s second law of diffusion. Upon drying of ultrasonic pre-treated black berry the drying time was increased five times as compared to the untreated samples.

Effect of relative humidity: The effect of humidity below 30% RH and temperature in the drying kinetics of kenaf core was studied by Misha et al. [43]. Temperature (45, 50 and 55°C) and relative humidity (10, 20 and 30%) variations at an air velocity of 1.0 m/s was used for drying. Two term model described the drying kinetics more accurately then the rest of the models used in the experiment. The drying time was found to be reduced as the temperature increased at constant air humidity. Relative humidity of the air rather had an insignificant effect on the drying curve of the kenaf core; this could be attributed to the initial moisture content of the sample. Effect of humidity from 40 to 45% RH on pre-treatment was observed in the experiment conducted by Bai et al. [51] a high humidity of 40 to 45% were used for pre-treatment of grapes using the novel method of HHAIB treatment and impingement drying. Grapes were treated using HHAIB for 30, 60, 90, or 120 s and then cooled at 25°C. It is then dried using air impingement dryer. It was observed that HHAIB treatment significantly affected the drying kinetics as compared to the temperature. It was also observed that grapes dried using HHAIB have a more appealing end colour of the product. Pre-treatment at 110°C for 90 s was found to be the most effective to produce a desirable end product. Inazu et al. [53] analysed the effect of relative humidity above 60% RH and temperature in the drying kinetics of Japanese noodle (Udon). Relative humidity of 60, 70 and 80% were used. Drying of the noodle was done at three different temperatures of 20, 30 and 40°C and a modified Arrhenius model was used to describe the effect of relative humidity on the drying kinetics. During constant temperature, drying rate decreased as the relative humidity increased and as temperature increased, the drying rate increased at constant relative humidity. There was insignificant effect of relative humidity on the apparent moisture diffusivity. During the initial stage at 20°C and a relative humidity of 60%, the value of apparent moisture diffusivity was 9.8 m2/s where as it was 10.82 m2/s at 40°C at the end of the initial phase of drying at relative humidity of 80%. During the main stage of drying at a temperature of 20°C and relative humidity of 60°C the apparent moisture diffusivity was 4.75 m2/s and at the end of the process at a temperature of 40°C and relative humidity of 80%, the apparent moisture diffusivity was found to be 6.25 m2/s.

Commercial dried products

Various dried products are available commercially. The method of drying varies according to the product that is to be dried. Drying increases the shelf life of the product and its commercial value.

Dried meat products: Drying of beef in super-heated steam and hot air was studied by Speckhahn et al. [54]. Super-heated steam was found to have a quicker drying rate. Temperature exceeding 160°C caused changes on the meat surface and prevents the bound moisture to escape through the meat surface due to case hardening. It was also found that fat is more efficiently extracted when super-heated steam as compared to hot air oven. Baslar et al. [55] experimented on a novel method of drying beef and chicken by using ultrasonic vacuum drying to shorten the drying period of beef. The experimental result showed that the method is efficient and have potentials to be used in meat and poultry industries. Fish is a good source of animal protein and contains vitamins and minerals required for the nutrition but are extremely perishable. Fish and fish by-products are also a good source of omega 3 polyunsaturated fatty acids and contain large amount of EPA (eicosapentaenoic acid) and DHA (docosahexaenoic acid) which plays an important role in food and pharmaceutical products, spray granulation at ±70°C shows less chance of degradation of lipids as compared to drying at higher temperature in fish [56].

Powdered products: Spray drying is now the most commonly used procedure for dairy products, involves atomization of the liquid feed and instantaneous drying of milk components. The application of spray drying in the development of fruit powder is on the rise due to its simplicity and affordability [57]. The study conducted by Malafronte et al. [58] showed that high fat content resulted in longer period of drying with a less shrivelled particle in skim milk, light milk, medium milk and whole milk when dried in a single drop drying kinetics device. A schematic representation of spray dryer is illustrated in Figure 3F. The influence of spray drying on the properties of egg white powder (EWP) and optimization of the process was studied by Ma et al. [59]. The optimum feeding and inlet air temperature were 39.8°C and 178.2°C, respectively. The feed rate was 22 ml/ min. Under these conditions the hydratability and solution index was 5.832 ml/g and1.9835 respectively. Sulfydryl group measurements indicated change in conformation and a decrease in its content was observed. Koc et al. [60] studied the effect of spray drying in the functional and physicochemical properties of whole egg powder. An outlet air temperature of 60°C and an inlet air temperature of 195°C at an atomization pressure of 294 Kpa resulted lowest water activity in the powder samples. However, the maximum peroxide value (0.799) for the whole egg powder was obtained at the outlet air temperature of 80°C. The effect of solar drier and tunnel drier on the physiochemical properties of tomato powder was studied by Ghavidel and Davoodi [61]. Tunnel dryer was found to be a more effective method of drying as compared with the solar drying.

Drying of cereals and pulses: The conventional method of processing pulse is to split the pulse by de-hulling which causes a loss of 15 to 20% and so pre-treatment is required to reduce the loss and for easy milling. Less energy consumption for cooking and drying as compared with other method is a major advantage of drying pulse. Currently continuous flow microwave heating method is replacing the batch method of pre-treatment for dehulling pulse in industrial scale [62]. Sharon et al. [63] studied the influence of air temperature (40 to 60°C), bed depth (0 to 0.6 m) and drying time (1 to 9 h) on the deep bed drying of black gram. Increase in bed depth and air velocity decreased the moisture content of the sample at all the temperature. Drying at 40°C reduces energy consumption and drying at 60°C saved the time for drying.

Dried cultures: Long term stabilization of culture is required to maintain the viability of cultures for long term storage and utilization of valuable culture organism used for food formulation. Freeze drying is the standard process for the production of dried starter cultures [64]. Gradually dried culture substrate for enzyme production in anon-airflow solid state fermentation process was investigated by Ito et al. [65]. The drying process had a positive effect by increasing the enzyme production but decreased the mycelium content weight basis. Commercial dried cultures are now available throughout the world.

Dried fruits and vegetables: Originally, fruits and vegetables were dried using sun drying, however, due to the poor quality of the end product and high chances of contamination newer alternative methods were used [1]. Osmotic dehydration of fruits and vegetables results in the shrinkage of the final product [66]. The condition of air such as temperature, humidity and velocity of the drying air affects the drying kinetics during drying. The size of the sample to be dried is also another factor that affects the drying of fruits and vegetables [67]. Different drying techniques affect the properties of the material dried. Kunar [68] investigated the influence of tray load on the drying kinetics, osmotically treated mango, guava slices and anola segments were dried in a cabinet dryer, low temperature drier and vacuum dryer having the tray load of 0.30, 0.35, 0.40 and 0.45 g/cm2respectively. The vacuum and cabinet drying method with a tray load of 0.40 g/cm2 was found to be the optimum condition for drying. Some of the drying methods used to dry fruits and vegetable are given in Table 2. High energy consumption and cost is a major problem associated with drying fruits and vegetables. Utilisation of solar energy provides an alternative to drying fruits and vegetables since it is less expensive and uses a clean source of energy [2]. The use of infra-red energy is a novel method of drying fruits and vegetables that causes the reduction of processing time and cost [11].

Table 2. Drying method used to dry some fruits.

| Products | Drying methods | References |

|---|---|---|

| Guava | Solar drying Vacuum oven drying Cabinet drying |

[3] |

| Mango | Osmo-convective drying Solar drying Tray drying |

[3] [23] [68] |

| Anola | Vacuum drying Osmotic drying Cabinet drying |

[3] [36] [68] |

| Apple | Fluidised bed Explosion puff drying |

[5] [8] |

| Carrot | Infrared drying Spray drying |

[11] [74] |

| Garlic | Convective pre drying Vacuum-microwave Air drying |

[12] [46] |

| Jack fruit | Hot air drying Osmo-convective drying |

[13] [29] |

| Straw berry | Microwave-Vacuum drying Solar drying Convective drying |

[15] [24] [26] |

| Banana | Natural convection Vacuum freeze-drying |

[15] [75] |

| Mushroom | Hot air drying Microwave-vacuum drying Osmotic dehydration |

[16] [16] [30] |

| Tomato | Infra red drying Hot air drying Solar drying |

[17] [47] [61] |

| Grapes | Osmo-convective drying Hot air drying |

[31] [51] |

Combination of drying techniques can reduce the energy consumption and produce a better quality product. Long drying time and high temperature used during the dehydration process leads to the loss of vitamins, colorants and antioxidants even if the drying is carried out at low temperature exposure of the fruits and vegetables to oxygen could lead to the significant reduction in the nutrient content [12].

Future opportunities

Though good feeds have been achieved in drying technology there is a need for further development of cost effective and energy efficient methods of drying. During the drying process the desirable aspects of fruits and vegetables needs to be preserved. Combinations of drying techniques produces products which are more appreciated by the consumers and reduces the heat induced deteriorations in fruits and vegetables. Consumption of high amount of energy by instruments used for drying adds to the cost of the finished end product. The application of natural method of drying not only reduces the cost but is much easier to use. The major drawback of natural method of drying is that it is time consuming and the conditions of drying cannot be manipulated as compared to the artificial method of drying. Future work could focus on developing natural drying solutions with greater efficiency. Drying kinetics has helped to achieve good and effective result with minimal resource utilization. However, drying models that take all the variables into consideration are still non-existing, which makes it a potential area of research.

References

- Sontakke MS, Salve P. Solar drying technologies: A review. International Journal of Engineering Science. 2015;4:29-35.

- Zhang M, Tang J, Mujumdar AS, et al. Trends in microwave related drying of fruits and vegetables. Trends in Food Science & Technology. 2006;17:524-34.

- Kumar PS, Sagar VR. Drying kinetics and physicochemical characteristics of osmo dehydrated mango, guava and aonla under different drying conditions. International Journal of Food Science & Technology. 2014;51:1540-46.

- Yousefi A, Niakousari M, Moradi M. Microwave assisted hot air drying of papaya (Carica papaya L.) pretreated in osmotic solution. African Journal of Agricultural Research. 2013;8:3229-35.

- Askari GR, Emam-Djomeh Z, Mousavi SM. Heat and mass transfer in apple cubes in a microwave assisted fluidized bed dryer. Food and Bioproducts Processing. 2013;91:207-15.

- Kahyaoglu LN, Sahin S, Sumnu G. Spouted bed and microwave assisted spouted bed drying of parboiled wheat. Food and Bio products Processing. 2012;90:301-08.

- Abbasi S, Azari S. Novel microwave-freeze drying of onion slice. International Journal of Food Science & Technology. 2009;44:947-79.

- Bi J, Yang A, Liu X, et al. Effect of pretreatments on explosion puffing drying kinetics of apple chips. International Journal of Food Science & Technology. 2015;60:1136-42.

- Garba U, Kaur S, Rasane P, et al. Effect of hot water blanching time and drying temperature on the thin layer drying kinetics and anthocyanin degradation of black carrot (Daucus carota l.) shreads. Food Technology and Biotechnology. 2015;53:324.

- Borquez R, Melo D, Saavedra C. Microwave–vacuum drying of strawberries with automatic temperature control. Food and Bioprocess Technology. 2014;8:266-76.

- Xu C, Li Y, Yu H. Effect of far-infrared drying on the water state and glass transition temperature in carrots. Journal of Food Engineering. 2014;136:42-47.

- Calin SA, Figiel A, Wojdyio A, et al. Drying of garlic slices using convective pre drying and vacuum-microwave finishing drying: kinetics, energy consumption and quality studies, Food and Bioprocess Technology. 2014;7:398-408.

- Saxena A, Maity T, Raju P, et al. Degradation kinetics of color and total carotenoids in jackfruit (Artocarpus heterophyllus) bulb slices during hot air drying. Food and Bioprocess Technology. 2012;5:672-79.

- Doymaz I. Infrared drying of sweet potato (Ipomoea batatas L.) slices. International Journal of Food Science & Technology. 2012;49:760-66.

- Borges SV, Manicini MC, Correa JLG, et al. Drying kinetics of banana by natural convection: Influence of temperature, shape, blanching and cultivar. Ciencia Agrotecnologia. 2011;35:368-76.

- Giri SK, Prasad S. Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot air dried button mushrooms. Journal of Food Engineering. 2007;78:512-21.

- Sadin R, Chageni GR, Sadin H. The effect of temperature and slice thickness in drying kinetics tomato in the infrared dryer. International Journal of Heat and Mass Transfer. 2014;50:501-07.

- Schossler K, Jager H, Knorr D. Novel. Contact ultrasound system for accelerated freeze-drying of vegetables. Innovative Food Science and Emerging Technologies. 2012;18:433-45.

- Toshniwal U, Karale SR. A review paper on solar dryer. Int. Journal of Engeneering. 2013;3:896-902.

- Ahrens DC, Villela FA, Doni Filho L. Physiological and industrial of quality white oat seeds (Avena sativa) in intermittent drying. Revista Brasileria de Sementes. 2000;22:12-20.

- Okoro OI, Madueme TC. Solar energy investments in developing economy. Renew. Energ. 2004;29:1599-1610.

- Fudholi A, Sopian K, Ruslan MH, et al. Review of solar dryers for agricultural and marine products. Renewable and Sustainable Energy Reviews. 2010;14:1-30.

- Madhlopa A, Jones SA, Saka JDKA. Solar air heater with composite-absorber systems for food dehydration. Renewable and Sustainable Energy Reviews. 2002;27:27-37.

- El-Beltagi A, Gamea GR, Essa AHA. Solar drying characteristics of strawberry. Journal of Food Engineering. 2007;78:456-64.

- Brennan JG, Grandison AS. Evaporation and Dehydration. Food Processing Handbook. Wiley VCH Verlag GmbH and Co. KGaA, Weinheim, Germany. 2006;71:124.

- Morales-Delgado DY, Tellez-Medina DI, Rivero-Ramerez NL, et al. Effect of convective drying on total anthocyanin content, antioxidant activity and cell morphometric parameters of strawberry parenchymal tissue. Revista Mexicana de Ingeniera Quimica. 2014;13:179-87.

- Doymaz I. Convective drying kinetics of strawberry. Chem. Eng. Proc. 2008;47:914-19.

- Loha C, Das R, Choudhury B, et al. Evaluation of air drying characteristics of sliced ginger (Zingiber officinale) in a forced convective cabinet dryer and thermal conductivity measurement. Food Processing and Technology. 2012;3:1-5.

- Kaushal P, Sharma HK. Osmo-convective dehydration kinetics of jackfruit (Artocarpus heterophyllus). Journal of the Saudi Society of Agricultural Sciences. 2014;15:118-26.

- Mehta BK, Jain SK, Sharma GP, et al. Response Surface Optimization of osmotic dehydration process parameters for button mushroom (Agaricus bisporus) part I. Focusing on Modern Food Industry. 2013;2:91-102.

- Grabowski S, Mujumdar AS, Ramaswamy HS, et al. Osmo-convective drying of grapes. Drying Technology. 2007;12:1211-19.

- Falade KO, Igbeka JC. Osmotic dehydration of tropical fruits and vegetables. Food Reviews International. 2007;23:373-405.

- Harnkarnsujarit N, Charoenrein S. Influence of collapsed structure on stability of ß carotene in freeze-dried mangoes. Food Reviews International. 2011;44:3188-194.

- Shi J, Maguer ML. Osmotic dehydration of foods: mass transfer and modeling aspects. Food Reviews International. 2002;18:305-35.

- Chavan UD, Amarowicz R. Osmotic dehydration process for preservation of fruits and vegetables. Journal of Food Research. 2012;1:202.

- Alam, MS, Singh A, Sawhney BK. Response surface optimization of osmotic dehydration process for anola slices. International Journal of Food Science. 2010;47:47-54.

- Gupta SV, Patil N. Convective drying of osmo-dehydrated sapota slice. International Journal of Agricultural and Food Science. 2014;5:219-26.

- Khazaei J, Daneshmandi S. Modeling of thin-layer drying kinetics of sesame seeds: mathematical and neural networking modeling. International Agrophysics. 2007;21:335-48.

- Handerson SM. Progress in developing the thin layer drying equation. Transactions of the American Society of Agricultural Engineers. 1974;17:1167-72.

- Irudayaraj J, Haghighi K, Stroshine RH. Finite element analysis of drying with application to cereal grains. Journal of Agricultural Engineering Research. 1992;53:209-29.

- Kemp IC. Drying models, myths and misconceptions. Chemical Engineering & Technology. 2011; ;34:1057-66.

- Handerson SM, Pabis S. Grain drying theory I. Temperature effects on drying coefficient. Journal of Agricultural Engineering Research. 1961; 6:169-74.

- Misha S, Mat S, Ruslan MH, et al. The effect of drying air temperature and humidity on the drying kinetics of kenaf core. Applied Mechanics and Materials. 2013;315:710-14.

- Bruce DM. Exposedlayer barley during, three models fitted to new data up to 150 °C. J. Journal of Agricultural Engineering Research. 1985;32:337-47.

- Parry JL. Mathematical modeling and computer simulation of heat and mass transfer in agricultural grain drying.Journal of Agricultural Engineering Research. 1985;32:1-29.

- Krokida MK, Karathanos VT, Maroulis ZB, et al. Drying kinetics of some vegetables. Journal of Food Engineering. 2003;59:391-403.

- Abano E, Ma H, Qu W. Influence of air temperature on the drying kinetics and quality of tomato slices. Journal of Food Processing & Technology. 2011;2:123.

- Tzempelikos DA, Vouros AP, Bardakas AV. Case studies on the effect on the effect of the air drying conditions on the convective drying of quinces. Case Studies in Thermal Engineering. 2014;3:79-85.

- Bakal SB, Sharma GP, Sonawane SP. Kinetics of potato drying using fluidized bed dryer. International Journal of Food Science & Technology. 2012;49:608-13.

- Naderinezhad S, Etesami N, Najafabady AP, et al. Mathmatical modelling of drying potato slice in a forced convection dryer based on important parameters. Food Science & Nutrition. 2015;4:110-18.

- Bai J, Sun D, Xaio H, et al. Novel high humidity hot air impingement blanching (HHAIB) pretreatment enhances drying kinetics and colour attribute of seedless grapes. Innovative Food Science and Emerging Technologies. 2013;20:230-37.

- Romero CA, Byron J, Yepez V. Ultrasound as pretreatment to convective drying of Andean blackberry. Ultrasonics Sonochemistry. 2015;22:205-10.

- Inazu T, Iwasaki K, Furuta T. Effect of temperature and relative humidity on drying kinetics of fresh Japanese noodle (Udon). International Journal of Food Science & Technology. 2002;35:649-55.

- Speckhahn A, Srzednicki G, Desai DK. Drying of beef in superheated steam. Drying Technology. 2010;28:1072-82.

- Baslar M, Kilicli M, Toker OS, et al. Ultrasonic vacuum drying technique as a novel process for shortening the drying period for beef and chicken meats.. Innovative Food Science and Emerging Technologies. 2014;26:182-90.

- Ravichandran S, Joseph FRS, Kanagalakshmi R, et al. Variations in nutritive composition of two commercially important marine fin fishes. British Journal of Biomedical Science. 2012;8:43-51.

- Barbosa J, Teixeira P. Development of probiotic fruit juice powders by spray drying: a review. Food Reviews International. 2016.

- Malafronte, Aharne L, Schuster E, et al. Exploring drying kinetics and morphology of commercial dairy powders. Journal of Food Engineering. 2015;158:58-65.

- Ma S, Zhao S, Zhang Y, et al. Quality characteristics of spray drying egg white powder. Molecular Biology Reports. 2013;40:5677-683.

- Koc M, Koc B, Susyal G, et al. Functional and physicochemical properties of whole egg powder: effect of spray drying conditions. International Journal of Food Science & Technology. 2011;48:141-49.

- Ghavidel RA, Davoodi MG. Studies on physiochemical properties of tomato powder as affected by different dehydration methods and pretreatments. World Academy of Science, Engineering and Technology. 2010;69:596-605.

- Dronachari M, Yadev BK. Application of microwave heat treatment in processing of pulse. J. Acad. Ind. Res. 2015;3:401-07.

- Sharon M, Abirami CV, Alagusundaram K. Effect of drying air temperature, bed depth and drying time on deep bed drying of black gram using RSM. Indian Journal of Pulses Research. 2015;28:54-60.

- Forest P, Santivarangkna C. Advances in starter culture technology: focus on drying processes. Advances in Fermented Foods and Beverages: Improving quality, Technologies and health benefits. 2015.

- Ito K, Gomi K, Kariyama M, et al. Change in enzyme production by gradually drying culture substrate during solid state fermentation. Journal of Bioscience and Bioengineering. 2015;119:47-76.

- Nahimana H, Zhang M, Mujumdar AS. Mass transfer modeling and shrinkage consideration during osmotic dehydration of fruits and vegetables. Food Reviews International. 2011;4:331-56.

- Diamante LM, Munro PA. Mathematical modeling of hot air drying of sweet potato slice. International Journal of Food Science & Technology. 1991;26:99-109.

- Kumar PS, Sagar VR, Singh U. Effect of tray load on drying kinetics of mango, guava and anola. Journal of Scientific and Industrial Research. 2006;65:659-64.

- Tanaka F, Tanaka F, Tanaka A. Mathematical modeling of thin layer drying according to particle size distribution in crushed feed rice. Journal of Biosystems Engineering. 2015;136:87-91.

- Overhults DD, White GM, Hamilton ME, et al. Drying soybeans with heated air. Transactions of the American Society of Agricultural Engineers. 1973;16:195-200.

- Moses JA, Norton T, Ala gusundaram K, et al. Novel drying techniques for the food industry. Food Engineering Reviews. 2014;6:43-55.

- Ekechukwu OV, Norton B. Design and measured performance of a solar chimney for natural-circulation solar-energy dryers. Renewable energy. 1997;10:81-90.

- Monteiro RL, Carciofi BAM, Marsaioli A, et al. How to make a Microwave Vacuume dryer with turntable. Journal of Food Engineering. 2015;166:276-84.

- Mestry AP, Mujumdar AS, Thorat BN. Optimization of spray drying of an innovative functional food: Fermented mixed juice of carrot and watermelon. Drying Technology. 2011;29:1121-131.

- Qing-liang CUI. Study on the vacuum freeze drying process of bananas. Shanxi Agricultural University, (Natural Science Edition) 2008;2:28.