Research Article - Journal of Food Technology and Preservation (2022) Volume 6, Issue 5

Preparation, characterization and performance evaluation of 'enset' starch bio-plastic and its potential application for food packaging.

Bune Erre1, Temesgen D Desissa2*

1Department of Chemical Engineering, Addis Ababa Science and Technology University, 16417 Addis Ababa, Ethiopia

2Department of Material Science and Engineering, Adama Science and Technology University, Adama, Ethiopia

- *Corresponding Author:

- Temesgen D Desissa

Department of Material Science and Engineering

Adama Science and Technology University

Adama, Ethiopia

E-mail: sniochkaren@uclan.ac.uk

Received: 19-Apr-2022, Manuscript No. AAFTP-22-61330; Editor assigned: 21-Apr-2022, PreQC No. AAFTP-22-61330(PQ); Reviewed: 06-May-2022, QC No. AAFTP-22-61330; Revised: 09-May-2022, Manuscript No. AAFTP-22-61330(R); Published: 16-May-2022, DOI: 10.35841/2591-796X-6.5.121

Citation: Desissa TD. Preparation, characterization and performance evaluation of ‘‘enset’’ starch bio-plastic and its potential application for food packaging. J Food Technol Pres. 2022;6(5):121

Abstract

‘Enset’, (‘enset’e Ventricosum, Family Musaceae), is an indigenous starchy vegetable tree native to southern Ethiopia. In this work, we investigated the possibility to use starch extracted from ‘enset’ for bio-plastic production and its potential use for food packaging. The water extraction method was used to extract the starch from the ‘enset’ using sodium metabisulfite as a solvent. The average moisture content, ash content, crude protein and yield of extracted starch were investigated with the corresponding value of 16.82%, 0.031%, 0.27%, and 82.87%, respectively. Then, the bioplastic film of the starch was produced by a solution casting method. Expert design RSM and ANOVA analysis were used to determine the optimum process parameters combination to find the highest yield of bio-plastic formation. Accordingly, glycerol content of 7.48% was obtained at a reaction temperature of 130°C and a drying time of 1654.7 min. The predicted optimum bio-plastic yield was around 80%. Bio-plastic with 10% of glycerol was more sensitive to moisture absorption. The obtained water vapor transmission rate (WVTR) was about 12.6 g/m2•d, 22.353 g/m2•d and 35.82 g/m2•d at a different relative humidity (RH) of 25%RH, 40%RH, and 60% RH, respectively. The range of the glass transition temperature (Tg), crystallization temperature (Tc) and melting temperature (Tm) of bio-plastic sample was obtained from a differential scanning calorimetry (DSC), with the corresponding values of 50°C – 100°C, 200°C – 230°C and 275°C – 340°C, respectively. The average tensile strength of the bioplastic was about 49.4 MPa. As the thickness of the bio-plastic film increases both the white index and the light transmittance wavelength increased. Application test study on the packaging of a fresh cut banana indicated that the obtained bio-plastic from ‘enset’ starch can be used for alternative food packaging industries.

Keywords

‘Enset’ starch, Bio-plastic, Packaging, Sodium metabisulfite, Food packaging.

Introduction

Plastics are used in a wide variety of products and have replaced other materials, such as wood, metal, and glass for different food packing and medical applications. It is evident that plastics bring many societal benefits and offer future technologically advanced food packing and medical service due to their durability, low cost, higher water resistance and less energy consumption. However, most of the conventional plastics are produced from non-renewable resources such as natural gas and crude oil, which are heavily dependent on the declining reserves of fossil fuels. These plastics, once disposed to the environment, cannot undergo degradation easily and brings in an environmental pollution. As a result, the use of bio-based plastic is the most officinal case to replace the conventional plastics in food packaging industries. This can be achieved through development of a bio-polymer with durability matching the shelf-life of food products. The durability of bio-based plastics is one of the challenges faced by food packaging industries due to the requirements that the bio-based packaging material must remain stable, i.e., without changes in its mechanical and barrier properties regardless of its operation conditions.

Biopolymers can be derived from different natural resources mainly starch, proteins and fibers which at present are most obvious and easily available alternatives. The two major groups of biodegradable plastics positioned to enter the market in near future are polylactic acid and starch based polymers [1]. Biopolymers developed from starch have many advantages like higher biodegradability, easily available, its renewability and good barrier property in food packaging which makes them the most suitable alternative for some commercial applications. ‘‘enset’’ accumulates starch to approximately 99.24% of the dry weight base much greater than that of the potato that contain starch about 75% on dry weight based [2]. This suggests that ‘enset’ starch has a potential of replacing the corn and potato starch.

Food products could be damaged due to ambient environmental effects such as water, gases, light, odor or micro-organisms unless properly packed. A function of food packaging materials is to preserve food through transportation from the production plant to the market and thereby to the consumers. It may be possible to improve food quality and shelf-life by coating low moisture food products with biomaterial based coatings. These coatings prevent or retard water transfer from surrounding atmosphere to the food products [3]. This is important because water may initiate deterioration of food products and increase micro-organism activity. Bio-plastics can be used as barriers or retarders of water sorption of low moisture products. In this work, a starch was extracted from ‘enset’, followed by synthesis of bioplastic film by solution casting technique. The synthesized bioplastic properties such as mechanical, thermal, water vapor transmission rate, optical, and moisture absorption are studied with various techniques to have an overall insight on its potential application as food packaging material.

Highlight

• ‘enset’ starch extraction using sodium metabisulfite (Na2S2O5) as a solvent for bio- plastic film preparation.

• Effect of glycerol content on mechanical and physical property of a film produced for ‘enset’ starch.

• Application of ‘enset’ starch film for fresh cut banana packaging.

Materials

In this work, several materials and chemicals were utilized; Bulla (purchased from local market in Shashamane town, Oromia region, Ethiopia). Sodium hydroxide (NaOH), Sodium metabisulfite (Na2S2O5), hydrochloric acid (HCl), iodine (I2), glycerol (C3H8O3) and calcium chloride (CaCl2). All the chemicals were analytical grade. Stirrer, distilled water, beaker, mortar and pestle, large watch glass, Bunsen burner and heat proof mat, tripod and gauze, stirring rod, petri dish or white tile, universal indicator paper, pipettes, analytical balance, measuring cylinder are also utilized.

Materials and Methods

Sample preparation (‘enset’ starch extraction)

Starch extraction was carried out using the method described elsewhere [4]. Briefly, large quantities (2 kg) of bulla was dissolved in distilled water (DW) containing 0.075% (w/v) of sodium metabisulfite. The material was allowed to settle and the supernatant was decanted. The sediment starch was repeatedly treated with sodium metabisulfite solution until the suspension became translucent. The material was then passed through fine muslin to remove cell debris and the translucent suspension was collected and allowed to settle. The sediment starch was washed several times with DW, followed by sieving after each washing until the wash water was clear and free of suspended impurities. The resulting starch was dried in air at room temperature for 2 days and milled gently to fine powder with mortar and pestle. Then, the powder was sieved and made ready for further processing.

Composition analysis of starch from ‘enset’

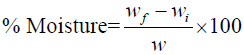

Moisture content: Moisture content (% of moisture) of starch was determined according to international standard method for moisture content determination by drying at 130°C in an oven. About 2 gram of starch sample was weighed and heated in the oven for 2 hrs. until constant weight was observed. The sample was then weighted, and the moisture content was determined using equation (1).

(1)

(1)

Where, wf is the final weight (before drying) and wi is the initial weigh of the start (before drying).

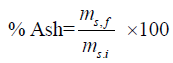

Ash content: Determination of ash contents of starch was done according to modified (ISO 3593) method for ash content determination. The starch was burned at high temperature of 350°C for 2 hrs in furnace. The starch ash content was calculated according to equation (2)

(2)

(2)

Where, ms,i and ms,f are mass of starch before and after burning, respectively.

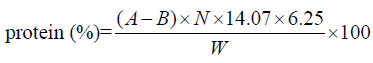

Crude protein content: Crude protein content of the ‘enset’ starch was determined according to (AOAC 2000). The Kjeldahl procedure can be basically divided into three parts: (1) digestion, (2) distillation, (3) titration by taking 1g of sample into digestion flask. About 5 gram of Kjeldahl catalyst and 200 ml of conc. H2SO4 was added to the flask. Then the flask was placed in an inclined position and heated gently until clear solution was obtained. The mixture was cooled and 60 ml of distilled water was added. The flask was immediately connected to digestion bulb on condenser and the tip of condenser was immersed in standard acid, followed by addition of 5-7 drop of mixture of indicator in receiver. The receiving solution is sulfuric acid and the titrant is sodium hydroxide (NaOH) and tashiro’s indictor was used. The mixture was titrated with standard 0.2 N HCl. The protein content was calculated as follows, equation (3):

(3)

(3)

Where, A is the volume (ml) of HCl used for sample titration, B is the volume (ml) of HCl for blank titration and N is normality of HCl.

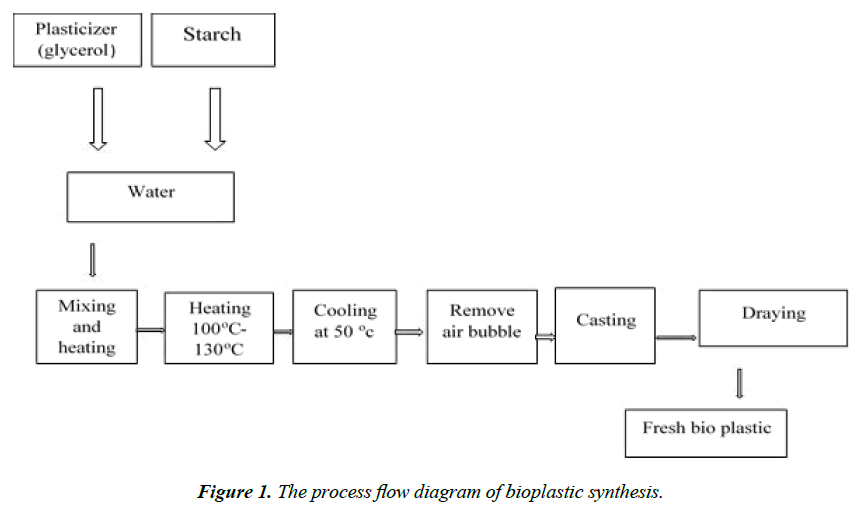

Bio-plastic formation process: There are various biomaterial film forming processes such as casting, spraying, extrusion and thermo-molding. The most common process to produce films on a laboratory scale is casting, which is used to produce free films for testing. In this process, a film forming solution is cast on a non-adhesive surface. Water or solvent is evaporated from the solution in order to form the bio-plastic [5]. As a result of solvent evaporation, biopolymer increases with the result that hydrogen bonds are formed and basic film structure is created. The overall schematics and process a flow diagram of bio-plastic processing is exhibited in the following figure 1.

Physicochemical characteristics of bio-plastic

Mechanical property: The mechanical property of the obtained bio-plastic was evaluated through tensile testing using methodology described by ASTM standard method D882-92 (ASTM2012). The test specimens were used with the size recommended by the ASTM standard for testing film polymer and the dimension were adjusted according to the size of the testing equipment [6]. The parameter evaluated was Young’s modulus and tensile strength. The young’s modulus E (MPa) and tensile strength σ (MPa) was determined from the stress-stain curve.

(4)

(4)

Thermal property: Differential scanning calorimetry (DSC) instrument provides very precise data, and can be very trustful in terms of measuring any melting point, transition temperature, and exothermic and endothermic nature of bioplastic and other properties of polymers. There is mainly two types of DSC methods, power compensated DSC and heat flux DSC. In power compensated method the sample material and reference materials are held in a separate, self-contained calorimeter each, with its own heater element. In the heat flux method, the material is placed in an aluminum and empty pan itself act as a reference. Heat flux method was used for this test, two pans also connects with heater which provides same temperature for material and reference. The advantage of using power compensated over heat flux DSC is that, the masses of the individual furnaces are much lower [7].

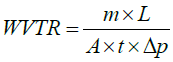

Water vapor transmission rate: Water vapor transmission rate (WVTR) of the film was studied gravimetrically using modified ASTM E 96 (2001) method. Anhydrous CaCl2 was used as a desiccant in a cup which was covered with studied film. Thickness of each film was measured with a micrometer at three randomly selected points after which the film was attached to the cup across the film at 25°C with different relative humidity (RH). Progress of water vapor permeation was determined gravimetrically as a function of time for 7 days. The cup was shaken horizontally after every weighing. Water vapor transmission rate was calculated according to the following equation (5).

(5)

(5)

Where m is the weight of water permeated through the film, L is film thickness, A is the permeation area of the film, t is time of permeation and Δp is water vapor pressure difference at both sides of the film.

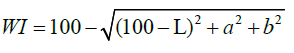

Optical properties: Optical property of the bioplastic film was investigated according to ISO 13468-1:1996 by using a UV spectrophotometer at the wavelength of 400-800 nm in every 5 nm. Whiteness index (WI) was calculated from spectral distribution of plastic samples. Color values of the films were measured with Minolta CR-400 Chroma meter using the international commission on illumination (CIE) scale L* a* b*. CIE indicated color where, L*(lightness), a*(red-green) and b* (yellow-blue) values are measured using reflectance measurements. WI (white index) of plastic samples was determined by placing samples on black reference. Plastic samples were covered over black reference ((L0: 25.96, a0: 0.69, b0: -0.10)), L, a, b values of samples were determined by using Chroma meter. WI of the sample calculated according the following equation (6).

(6)

(6)

Moisture absorption: The moisture absorption test of the synthesized bioplastic was preformed essentially according to the method described [8]. Small samples were prepared for each film concentration. The samples were brought to 4% RH by putting them into a moisture chamber containing silica gel that had been dried at 105°C for 2 hrs. The samples were kept in the chamber until their weight decrease ceased (weight difference less than 1%). The samples were then placed in a moisture chamber conditioned with a saturated salt solution of potassium sulfate (K2SO4), resulting in RH of 98%. The samples were weighed again until the weight increase came to a stop (weight difference less than 1%). A pure film was used as reference sample.

Results and Discussion

Moisture content

The moisture content of the ‘enset’ starch is the loss of the sample weight up on heating at high temperature under specified operating conditions. It was determined by taking the weight difference after the sample dried in oven at a temperature of 130°C. The average moisture content of ‘enset’ starch was found 16.82%, which is in accordance with the previous studies reported in 2007 that moisture content of ‘enset’ starch was ranged in between 4.7% to 19.1% [2,4]. Other studies indicated that the average moisture content of ‘enset’ starch was around 17.5% [2,9]. When the obtained value of moisture content of ‘enset’ starch was compared with potato and corn starch, the moisture content of ‘enset’ starch was higher both of it. Potato starch contains about 12.3% of moisture and corn starch contains moisture of about13.8% [10,11].

Determination of ash content

Ash content of ‘enset’ starch was determined by taking 2 g of sample and added in a burning cup (crucible) then; the sample was placed in a furnace. The average value of ash content for ‘enset’ starch was found to be around 0.0310%. Previous research indicates that the average ash content of ‘enset’ starch was from 0.014% to 0.029% [12]. The obtained result of the ash content of the ‘enset’ starch of this study is relatitevely higher than the reported value, which might be due to some solid materials left with starch from solvent during extraction. Washing of starch several times with warm and distilled water may reduce the ash content of ‘enset’ starch to its lower value.

Crude protein content

The mean value of protein content of ‘enset’ starch was determined by Kjeldahl methods and the average value was around 0.27%. This study reported that the average values of protein content for ‘enset’ starch were 0.81% [9]. Reported in 2008 that there were significant differences in protein content of five different ‘enset’ cultivators grown in Ethiopia, which ranged between 0.25-0.35% [13]. This reported that the crude protein content of corn starch was around 0.41% [2].

Physicochemical properties of bio-plastic

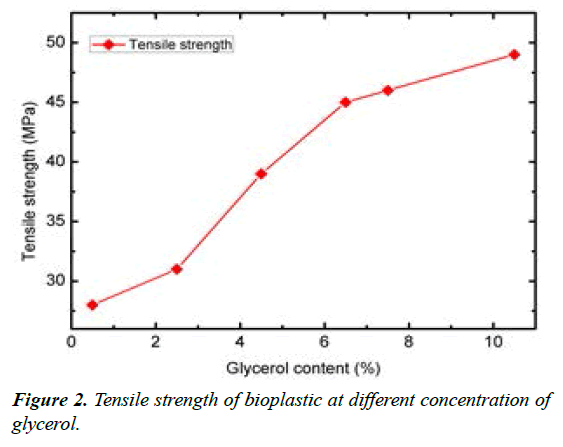

Mechanical property: As shown in figure 2, mechanical property of ‘enset’ starch bio-plastic, i.e., the values of tensile strength changed with glycerol content. The tensile strength increased from about 28 MPa at the lowest value of glycerol content to about 49.6MPa with the corresponding glycerol content of about 10%.

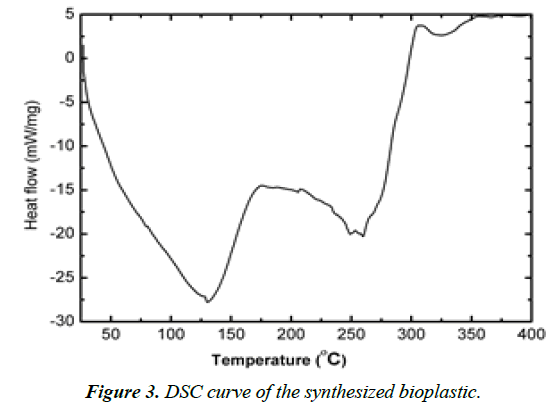

Thermal property: Figure 3 is the differential scanning calorimetry (DSC) curve of the thermal property of ‘enset’ starch based bio-plastic film containing 10% glycerol as plasticizer. The film glass transition temperature between onset and endpoint varied from 50°C to 100°C. Glass transition temperatures decreased as a result of plasticization. The glass transition temperature for films without plasticizer indicating that phase separation had not occurred. An endothermic peak was observed at temperatures of around 350°C. Those endothermic peaks were supposed to result from melting of starch crystallites in the films. DSC analysis also clearly indicates the melting and crystallization temperature of ‘enset’ starch bio-plastic. Melting temperature was seen before endothermic peak, the value of melting temperature range from 275°C-340°C and crystallization temperature observed before exothermic peak as indicated on the graph the crystallization temperature of ‘enset’ starch bio plastic were 200 °C-230 °C.

Water vapor transmission rate

Table 1 indicates that WVTR increases as ‘enset’ starch film samples get thinner with increasing relative humidity (RH). This result indicates that the film has a lower capacity to transfer water through its structure when it contains less water. On the other hand, the film plasticization probably increases diffusion rate of water in film and thus, WVTR increases with increasing plasticizer content. At lower RH, hydroxyl groups of starch form hydrogen bonds with hydroxyl groups of glycol so, glycerol plasticized films do not contain as many sorption sites for water as in starch film without plasticizer, this decreases diffusion rate of water molecules through the plasticized film. At higher RH, hydrogen bonding between starch and glycerol is disrupted by water sorption and amount of starch-water and glycerol-water interactions increases resulting in swelling of film and, thus, water diffusion through film increases (Table 1).

| Water vapor transmission rate(WVTR) g/m2.d | ||||

|---|---|---|---|---|

| Bio-plastic | Thickness (μm) |

25%RH | 40%H | 60%RH |

| Film | 15 | 17.08 | 31.46 | 47.9 |

| 25 | 11.25 | 21.6 | 33.4 | |

| 35 | 9.5 | 18.7 | 26.89 | |

Table 1. Water transmission rate of bio-plastic.

Optical property

Optical properties of plastics are related to the degree of crystallinity of the actual bio-plastic structure and thickness of the sample. As shown in table 2, as thickness of the bioplastic film increases, both white index and the transmittance wavelength increases. The loss of transparency of plastics results from refraction, absorption and scattering of light. Refractive index, reflection coefficient and dissipation coefficient affect transmittance most. Therefore, size of crystalline, molecular weight and molecular structure play big roles in optical properties of plastic. The clarity of a film indicates the degree of distortion of an object when viewed through the film, with ‘see-through’ clarity referring to the ability of the film to resolve fine details of fairly distant images viewed through the film (Table 2).

| Optical property | |||

|---|---|---|---|

| Bio plastic | Thickness ( | White index | Transmittance at wave length (400- 800nm) % |

| Film | 15 | 38.7 | 47.8-69.1 |

| 25 | 41.2 | 45.1-58.2 | |

| 35 | 43.8 | 43.2-57.3 | |

Table 2. Optical values of bio-plastic sample.

Moisture absorption

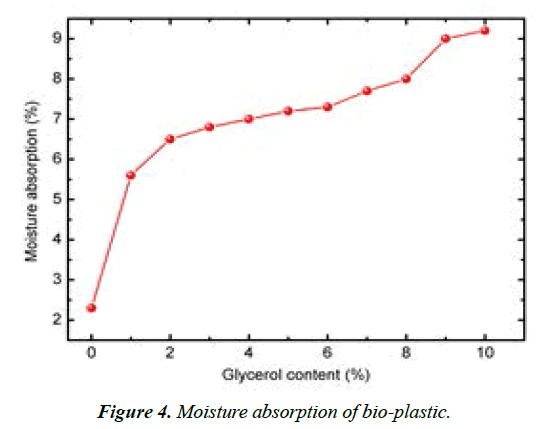

As indicated in figure 4, the synthesized bio-plastic from ‘enset’ starch with higher plasticizer content is more sensitive to moisture. The moisture absorption increases when glycerol present in the film increase. These results are in line with values found in literature for rice and potato starch (Figure 4) [14].

Application test of bio- plastic for food packaging

In this study, packaging containers made from bio plastic and PET (poly ethylene terephthalate) were tested for their ability to preserve the quality of fresh-cut banana fruit under 25°C temperature conditions. PET name belonging to poly ester derived from crude oil and natural gas use for common packaging and container in food industry. The choice of packaging material was made with the objectives to compare the effects of a petroleum-based packaging material versus a bio-based packaging material with comparable properties on the changes in quality of fresh-cut banana [15]. Why banana fresh cut interested was fresh-cut fruit and vegetables represent an important food segment of interest to growers, processors, retailers and consumers. Quality in fresh-cut product preparation and distribution is crucial in terms of food safety, quality and environmental impact. The following property indicates quality of fresh cut fruit in packaging plastic [16].

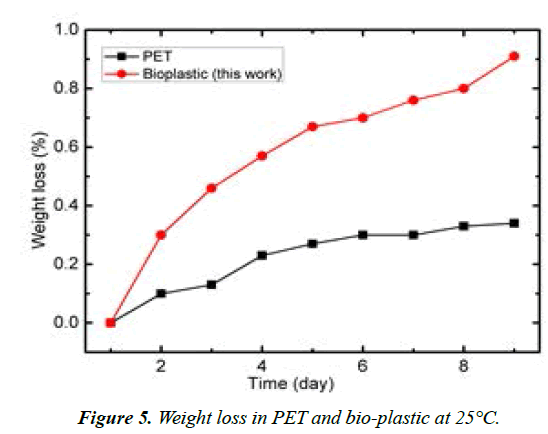

Weight loss

Figure 5 exhibits greater weight loss the bio-plastic packed banana than for the PET-packaged banana with percentage value of 0.40 at 25°C and 0.9 at 25°C respectively on the 9th sampling day [17]. The greater weight loss of banana in the bio-plastic containers was due to the higher water vapor transmission rate (WVTR) as described above.

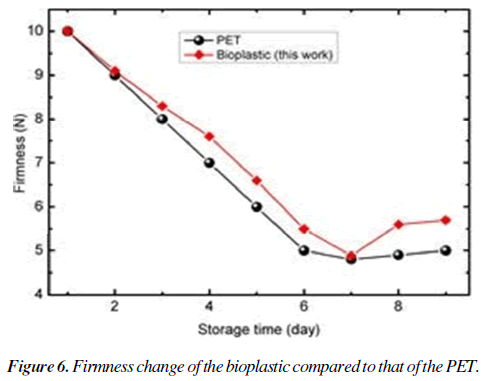

Firmness

Texture of fresh-cut fruit is a very important quality parameter. Tissue softening is one of the major challenges that limit the shelf life of fresh-cut fruit, and firmness is an important factor that influences the consumer acceptability of these products [18]. Firmness of fresh-cut banana in bio-plastic and PET containers decreased from 6.4 N to 4.4 N throughout the storage period at 25°C respectively. Firmness values of samples stored in bio-plastic containers at 25°C was slightly lower than PET throughout the storage period, as indicated in the following figure 6.

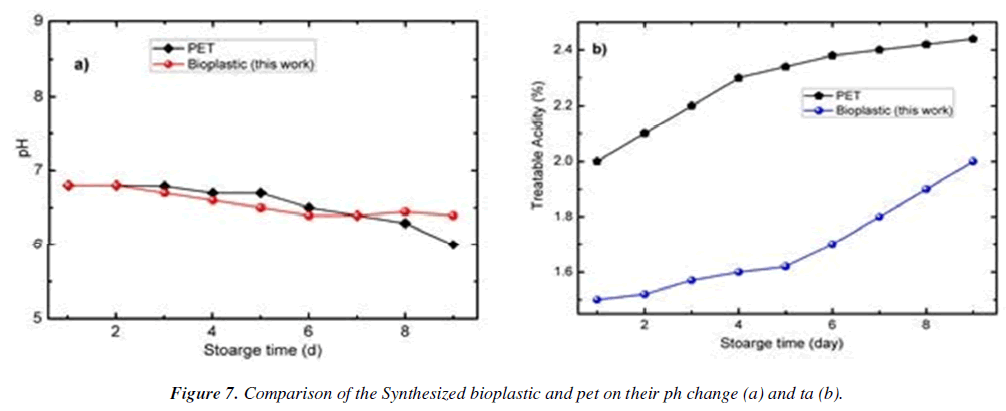

Flavor

As shown in Figure 7 (a) and (b), the pH and treatable acidity (TA) of fresh-cut banana in bio-plastic and PET containers declined during storage at 25°C. TA values showed only slight increases. The container’s temperatures showed no significant difference in pH or TA between the packaging materials [19]. The bio-plastic and PET values ranged pH of 6.3 - 6.6 and TA of 1.7% - 2.4%, respectively. Although there were no significant differences between bio-plastic and PET at the same temperature bio-plastic containers showed higher scores during evaluation (Figure 7).

Conclusion

Starch is a desirable candidate for making plastic packaging material due to its abundance, world wide availability and promising film forming properties. The extracted starch was characterized of properties such as moisture content, crude ash, crude protein and yield with the corresponding values of 16.89, 0.031, 0.27and 82%, respectively. According to RSM analysis, optimum process condition to the highest bio-plastic formation yield was found to be the combination of following key parameters. Reaction temperature: 130°C, drying time: 1654.7min and glycerol content 7.48. Under these conditions, the model predicted the bio-plastic yield was around 80% with desirability prediction of 0.96. The physicochemical properties of the bio-plastic under the optimized condition were mechanical property, thermal property, water transmission rate, optical property and moisture absorption. In this study, the application of produced plastic was tasted in terms of weight loss, firmness and flavor compared for quality food packaging material, that the synthesized bio-based plastic produced from ‘enset’ starch showed comparable properties to those of petroleum-based PET packaging. In general, the bio plastic synthesized in this work would be an appropriate alternative food packaging material.

Acknowledgements

The authors gratefully acknowledge the support of Addis Ababa science and Technology University fund to carry out the research work.

References

- Stevens CV. Bio-based plastics: materials and applications. John Wiley & Sons; 2013.

- Tsegaye A, Struik PC. Analysis of enset (Ensete ventricosum) indigenous production methods and farm-based biodiversity in major enset-growing regions of southern Ethiopia. Exp Agr. 2002;38(3):291-315.

- Coles R, McDowell D, Kirwan MJ, editors. Food packaging technology. CRC press; 2003.

- Belachew G, Gebre-Mariam T. Cross-linking enset starch microspheres, physicochemical characterization and study on their drug loading and release properties. Ethiop Pharm J. 2009;27(2).

- Thomazine M, Carvalho RA, Sobral PJ. Physical properties of gelatin films plasticized by blends of glycerol and sorbitol. J Food Sci. 2005;70(3):E172-6.

- Mali S, Grossmann MV, García MA, et al. Effects of controlled storage on thermal, mechanical and barrier properties of plasticized films from different starch sources. J Food Eng. 2006;75(4):453-60.

- Roos Y, Karel M. Plasticizing effect of water on thermal behavior and crystallization of amorphous food models. J Food Sci. 1991 Jan;56(1):38-43.

- Koch K, Johansson D, Johansson K, et al. Material properties and molecular aspects of highly acetylated starch-based films. J Renew Mater. 2014;2(2):134-44.

- Wondimu A. Preparation and characterization of pregelatinized enset starch and evaluation of its use as binder and disintegrant in tablet formulations (Doctoral dissertation, Addis Ababa University).

- Van den Berg C, Kaper FS, Weldring JA, Wolters I. Water binding by potato starch. Int J Food Sci Tech. 1975;10(6):589-602.

- Tester RF, Karkalas J, Qi X. Starch-composition, fine structure and architecture. J Cereal Sci. 2004;39(2):151-65.

- Gebre?Mariam T, Abeba A, Schmidt PC. Isolation and physico?chemical properties of enset starch. Starch Stärke. 1996;48(6):208-14.

- Arvanitoyannis I, Biliaderis CG, Ogawa H, et al. Biodegradable films made from low-density polyethylene (LDPE), rice starch and potato starch for food packaging applications: Part 1. Carbohydr polym. 1998;36(2-3):89-104.

- Biliarderis CG. Structure and phase transitions of starch in food system. Food Technol. 1992;46:98-109.

- Bravin B, Peressini D, Sensidoni A. Development and application of polysaccharide–lipid edible coating to extend shelf-life of dry bakery products. J Food Eng. 2006;76(3):280-90.

- Cisneros?Zevallos L, Krochta JM. Dependence of coating thickness on viscosity of coating solution applied to fruits and vegetables by dipping method. J Food Sci. 2003;68(2):503-10.

- Girma M, Abegaz B. Studies on the microbial flora of Kocho and Bulla purchased from markets in Addis Ababa. SINET: Ethiop J Sci. 1985;8(1 & 2):29-36.

- Bezuneh T, Feleke A. The production and utilization of the genus Ensete in Ethiopia. Econ Bot. 1966:65-70.

- Van Soest JJ, Knooren N. Influence of glycerol and water content on the structure and properties of extruded starch plastic sheets during aging. J applied polymer sci. 1997;64(7):1411-22.