Research Article - Journal of Food Technology and Preservation (2021) Volume 5, Issue 8

Modulation of shelf life and postharvest quality of pear cv. ?Bartlett? during post cold ambient storage after cacl2 treatments.

Satish Kumar*

Department of Food Science and Technology, Y. S. Parmar University of Horticulture and Forestry, Nauni, Solan, Himachal Pradesh, India

Corresponding Author:

- Satish Kumar

Department of Food Science and Technology, Y. S. Parmar University of Horticulture and Forestry, Nauni, Solan, Himachal Pradesh, India

E-mail: caanyu@musph.ac.ug

Accepted date: 20 September, 2021

Citation: Satish Kumar. Modulation of shelf life and postharvest quality of pear cv. ‘Bartlett’ during post cold ambient storage after cacl2 treatments. Journal of Food Technology and Preservation 2021;5(8):1-5.

Abstract

Response of ‘Bartlett’ pears to various post-harvest CaCl2 treatments under cold storage (2°C ± 1°C with 95% ± 2% RH) conditions and periodic shelf life periods under ambient conditions (24 ± 3ºC; 68 ± 5 % RH), was recorded as changes in some important quality parameters. The fruits were dipped in 10, 20, 30 and 40 g kg-1 CaCl2 for 10, 20 and 30 min, air dried and were packed in Corrugated Fiber Board (CFB) boxes (29 × 23 × 14 cm; L × B × H). Fruits treated with 30 and 40 g kg-1 CaCl2 for 30 min recorded maximum firmness, soluble solids, titratable acidity, ascorbic acid, total phenols and calcium content with minimum spoilage, weight loss, Pectin Methyl Esterase (PME) and Polygalacturonase (PG) activity with highest scores for all the sensory parameters. The treatment effect was compared by Duncan’s new multiple range test which revealed some significant differences during shelf life periods under ambient conditions while, the post-hoc analysis by Tukey’s test showed significant differences among the sensory parameters.Keywords

CaCl2 treatment, cold storage, post cold ambient storage, quality changes, storage life.

Introduction

In recent years, there has been a continuous increase in the demand for fresh produce in the market resulting in the increase in the market size by using some conventional technologies for shelf life extension of fresh produce and assured unrestricted supply year around. With this aim the industries and research personals are deliberately trying to prepare new, innovative and more effective formulations or improvements in the existing technologies to achieve this goal. Pear is an important fruit crop of the temperate regions of the world and is grown in India on a large scale. Among different cultivars of pear grown in India Bartlett pear (green and red colored) is economically important due to some unique features like distinctive shape (obtuse-pyriform), aroma, texture, balanced sweet taste and strong recognition by the consumer. The harvesting season of the pears coincides with heavy rainfall and high temperature, conducive for ripening and may result in rapid deterioration of the fruit quality, also giving the farmers and marketing personals little time to sell their produce. Refrigerated storage of fruits immediately after harvesting slows down ripening and preserves the fruit quality. However, the availability of cold storage facilities is limited and ripening once initiates it proceeds so quickly that the actors in the food chain have a little time to manage market which ultimately yields huge losses [1].

Calcium is an essential cell wall ingredient to regulate fruits maturation and ripening while, its application have been reported to prevent many physiological disorders, increase disease resistance and delay ripening of many fruits. Calcium is generally applied as pre harvest spray and post-harvest dip treatments to achieve these benefits however, there is great disparity in range of CaCl2 concentrations used by different authors while, absorption and penetration of CaCl2 may also get affected by the fruit properties like skin thickness, number of lenticels on skin etc. Ripening of pear is characterized by rapid softening due to activity of Pectin Methyl Esterase (PME) and Polygalacturonase (PG) which break the complex structure of pectic substances to decreases their firmness. Ripening is associated with various physic chemical changes which makes the fruit edible while, if is uncontrolled, can render the fruits inedible or spoiled. Conclusively, the reports on post-harvest application of CaCl2 for the extension of shelf life of the fruits are highly inconsistent. Further, the data available shows that most of the studies in the concerned field have reported the behavior of fruits either under ambient or under cold storage conditions. However, during marketing of such fruits it is not always possible to maintain similar storage conditions, further at retail level fruits are generally held under ambient conditions which are conducive for ripening. Therefore, it is important to examine the behavior of treated fruits during ambient holdings after periodic cold storage to evaluate the actual shelf life of the fruits. Keeping in view the potential of CaCl2 in retaining the storability of fresh fruits and effect of different storage environments on post-harvest quality and shelf life of the fruits, the present study was aimed at the standardization post-harvest CaCl2 treatment for its potential effect of storability of the fruits during cold and post cold ambient storage periods.

Materials and Methods

Sample collection: Fresh pears cv. ‘Bartlett’ were harvested at commercial fruit maturities (10.64 kg cm-2 firmness and 3.15 starch iodine rating) in last week of July during 2015-16 and 2016-17 from a commercial fruit orchard of Kotkahi-Shimla, India (31°7'0" North, 77°32'0" East). Fruit were stored overnight at 20ºC, the very next morning fruits were sorted and randomized and only fresh, healthy and disease free fruits were selected for the treatment application.

Fruit treatment: CaCl2 solutions were prepared in different concentrations i.e. 10, 20, 30 and 40 g kg-1 in double distilled deionized water and the fruits were dipped in different prepared concentrations for 10, 20 and 30 min, respectively. During treatment it was made sure that the fruits were well below the surface of water to ensure equal absorption of CaCl2. After treatment fruits were air dried and were packed in CFB boxes (29 × 23 × 14 cm; L × B × H) and stored under refrigerated conditions (2°C ± 1°C with 95 ± 2%). Fruit were evaluated for different physical, biochemical and sensory changes on monthly intervals and thereafter on a successive interval of 3 d under ambient holdings to observe their ripening behavior [2].

Physical Parameters

Fruit firmness: Fruits were evaluated before treatment and immediately after each storage interval for changes in firmness with the help of digital fruit hardness tester equipped with a pressure head 8 mm in diameter (Lutron fruit hardness tester, FR-5120, Taipei, Taiwan) measured objectively on two sides of each fruit. The force required to insert the probe into the fruit was expressed as kg cm-2.

Physiological loss of weight: Physiological loss of weight (PLW) was calculated as cumulative (%) loss in weight based on the initial fruit weight (before storage) and loss in weight after periodical sampling during storage.

Spoilage: Spoilage (%) was calculated by noting the number of fruits spoiled (microbial and storage disorders) on each sampling date.

Biochemical parameters: The biochemical estimations were made by standard procedures.

Total soluble solids: Total soluble solids (TSS) content was measured by using Erma hand refractometer. The readings thus obtained were corrected for temperature variation to 20ºC as per the International temperature correction.

Ascorbic acid: Ascorbic acid was determined by 2, 6-dichlorophenolindophenol dye method which is based on the principle that 2, 6 -dichlorophenol indophenol is reduced to a colourless form by ascorbic acid. The reaction is specific for ascorbic acid at pH 1 to 3.5. The dye is blue in alkaline solution and red in acid.

Titratable acidity: Titratable acidity was estimated as per standard procedure by titrating a known volume of sample with NaOH solution against phenolphthalein as indicator after making the acids freely available which are otherwise not titratable.

Total phenols: Total phenols were estimated according to method of Jiang. Phenols were extracted in 80% ethanol and estimated on the basis of their reaction with an oxidizing agent phosphomolybdate in Folin- Ciocalteau reagent under alkaline conditions. The absorbance of the mixture was analyzed at 765 nm by a UV spectrophotometer. Gallic acid was used as a standard and results are expressed as mg gallic acid equivalent.

Pectinmethylesterase activity: Pectin Methyl Esterase (PME) hydrolyzes methyl ester groups in pectin chains to form carboxylic groups, releasing methanol and H3O+ and hence changes the pH of reaction mixture which in turn reflects its activity. PME activity was measured by mixing 20 mL of 1.0 % pectin solution in 0.5 M sodium chloride (pH 7.0). To this, 10 mL of enzyme extract was added and the pH was adjusted to 7.0. The mixture was incubated for 24 h at 30ºC and then readjusted with 0.02 N NaOH to pH 7.0. Pectin methyl esterase units were expressed by the symbols PME (units/mL juice) which represents the milli equivalents of esters hydrolyzed per min per mL of juice. The quantity of NaOH used gives a measure of the free carboxyl groups released by activity of PME.

Polygalacturonase activity: The assay is based on decrease in viscosity that occurs as a result of the enzyme-catalyzed hydrolytic degradation of polygalacturonic acid. To measure Polygalacturonase activity 2 mL of enzyme extract (prepared by crushing fruit flesh), 4 mL of pectin in sodium acetate-acetic acid buffer (pH 5.2) and 1 mL of acetate buffer were mixed in a vortex mixture for 2 min The mixture was put into an Ostwald viscometer (Merck KGaA, Darmstadt, Germany, adjusted for outflow time of 80 to 100s with water at 20°C) through the smaller arm and the initial efflux time of the mixture was measured. After 16 h, again the efflux time of the mixture was measured and the % loss in viscosity was interpreted as being proportional to the PG activity.

Calcium content: Fruit calcium was analyzed by digestion method using flame photometer as per the method developed by Jackson. Fruit sample were digested in 20 mL di-acid mixture [(nitric acid (HNO3) and perchloric acid (HCLO4) in 4:1 ratio)] for 4-5 h until a clear transparent liquid approximately 1-2 mL was left in the flask. The final volume was made 100 mL with distilled water. Calcium content of digested samples was then estimated against the pre standardized flame photometer and was expressed as g kg-1 (fresh weight basis).

Sensory evaluation: Consumer preferences for the treated fruit samples were reported through the sensory evaluation after monthly intervals. The trained and semi trained staff members were given coded samples for three successive sessions including the whole fruits and slices for their judgment on overall acceptability of the samples based on their appearance, texture, flavour and texture. The evaluation was done by using the 9-point hedonic scale. The acceptability rating of the test samples under ambient conditions was correlated with pre standardized physicochemical attributes i.e the threshold level of TSS (10%), fruit firmness (3.15 kg/cm2) and PLW (<9.0 %).

Statistical Analysis

Statistical analysis results are presented as means of at least three independent determinations in form of pooled data of two consecutive years. Statistical evaluation was performed by using two-way analysis of variance (ANOVA) of the IBM SPSS Statistics program with a significance level α = 0.05. Duncan’s multiple-range test (p<0.05) and Tukey’s test (p<0.05) was used for mean separation during shelf life periods under ambient holdings and storage under cold storage conditions [3].

Results and Discussion

The post hoc analysis of the fruits during shelf life periods under ambient conditions revealed lowest mean fruit firmness values of 1.92 and 3.32 kg cm-2 during 9 and 3 d ambient storage after 30 and 60 d of cold storage in the control fruits. The treated fruits on the other hand had a storage life of 12, 9 and 6 d under ambient conditions after 30, 60 and 90 d of cold storage. 40 and 30 g kg-1 CaCl2 treatment for 30 min were most effective as they retained higher firmness values up to 12 d (3.61 and 3.37 kg cm-2) and 9 d (3.41 and 3.12 kg cm-2) of ambient holdings. After 90 d of cold storage, fruits treated with 30 g kg-1 CaCl2 for 20 and 30 min and those treated with 40 g kg-1 CaCl2 for 10, 20 and 30 min retained higher firmness and were still acceptable while, after 6 d shelf life period all the fruits had the firmness values much below the minimum acceptable firmness score of 3.15 kg/cm2. Firmness is significant factor that affects the acceptability rating of the fruits while, continuous reduction in the fruit firmness is attributed to flesh softening due to degradation of pectin by endopolygalacturonases like Pectinmethylesterase (PME) and Polygalacturonase (PG). The higher firmness values in the fruits may be correlated with the successive formation of calcium pectate which could strengthen the cell network. CaCl2 treatment has been reported to delay softening of the pear fruits previously.

CaCl2 treatments assisted in lowering PLW yet a notable increase in PLW was recorded in all fruits. The fruits treated with 40 and 30 g kg-1 CaCl2 for 30 min reported lowest PLW values during the shelf life periods of 12 (6.94 and 7.20 %), 9 (8.10 and 8.44%) and 3 d (7.01 and 7.12%) after 30, 60 and 90 d of cold storage (p≤0.05). Interestingly, with advancement in shelf life periods effect of higher concentrations of CaCl2 (g kg-1) and longer dipping time (20 g kg-1 for 30min, 30 g kg-1 for 30 min, 40 g kg-1 for 20 min and 40 g kg-1 for 30 min) was non-significant. Weight loss beyond certain limits may lead to shriveling, loss of freshness, appearance and quality of fresh produce. While, the continuous increase in PLW might be due to the respirational and transpirational losses. The lower PLW values in the fruits treated with CaCl2 on the other hand were correlated to reduced respiration which might have lowered down the sensitivity of fruits to ethylene and the respirator losses as well.

The spoilage (microbial and storage disorders) of fruits was significantly reduced by CaCl2 treatments which was proportionate to CaCl2 concentration and dipping time (Table 1). Control fruits after 30 and 60 d of refrigeration could be stored for 9 and 3 d under ambient conditions and spoiled completely on further storage under ambient holdings while after 90 d of cold storage such fruits lost their acceptability completely and were not fit for ambient holding. Lower spoilage incidence was noticed in fruits treated with different concentrations of CaCl2 with higher concentrations being more effective in controlling spoilage while effect of lower concentrations started to dissipate as storage interval increased especially under ambient holdings. Also, the effect of 30 and 40 % CaCl2 treatment for 30 min after different ambient holdings was not statistically significant (p≤0.05). The data further revealed a significant role of CaCl2 treatments in restricting various physiological processes to minimize the spoilage incidence and to slow down or restrict the physiological disorders [4].

Table 1. P-values from three-way ANOVA of factors storage interval, treatment, season and their interaction, on fruit firmness, spoilage, PLW, TSS, acidity, ascorbic acid content and overall acceptability of pear fruits.

| Firmness | PLW | Spoilage | TSS | Acidity | Ascorbic acid | Overall acceptability | |

|---|---|---|---|---|---|---|---|

| CD0.05 Storage interval (I) | 0.017 | 0.22 | 0.054 | 0.032 | 0.001 | 0.056 | 0.004 |

| Treatment (T) | 0.12 | 0.153 | 0.35 | 0.12 | 0.003 | 0.44 | 0.022 |

| Season (S) | NS | NS | < 0.001 | 0.002 | NS | 0.065 | NS |

| Storage interval × Season | <.0.004 | 0.002 | NS | 0.004 | NS | 0.004 | 0.001 |

| Storage interval × Treatment | 0.003 | 0.034 | 0.019 | 0.006 | 0.004 | 0.025 | 0.002 |

| Season × Treatment | NS | NS | 0.002 | NS | NS | 0.004 | NS |

| Storage interval × Season × Treatment | 0.014 | NS | 0.12 | 0.016 | NS | 0.016 | NS |

TSS content of the fruits increased in control fruits up to 60 d of cold storage followed by a sharp decline, while, fruits treated with 30 g kg-1 CaCl2 for 20 and 30 min dipping and 40 g kg-1 CaCl2 solution for 30 min reported a gradual increase in TSS content up to 90 d. Different CaCl2 treatments, assisted in retaining higher TSS values and fruits treated with 40 and 30 g kg-1 CaCl2, recorded higher TSS values after ambient shelf life periods of 12 (10.56 and 10.14 °B), 9 (10.32 and 10.15°B) and 3 d (10.23 and 9.87°B) following 30, 60 and 90 d cold storage. Hydrolytic conversion of complex polysaccharides, transformation of pectic substances and concentration of juice might have resulted in increased TSS while, decline in the solubles concentration during the later-half, might be due utilization of sugars as respiratory substrates. Higher TSS in fruits treated with CaCl2 during later stages of storage with a delayed full ripe stage has been reported previously in pear fruits which might be due to restricted physiological processes.

The ascorbic acid content of fruits treated with CaCl2 was generally higher than the untreated fruits. The lowest ascorbic acid content (4.52 and 6.12 mg/100g) was recorded in the control fruits during ambient holdings (24 ± 3ºC; 68 ± 5 % RH) for 9 and 3 d after 30 and 60 d of refrigeration (2 ± 1°C with 95 ± 2%). Among various treatment combinations, 40 and 30 g kg-1 CaCl2 treatments for 30 min retained the highest ascorbic acid during post cold ambient shelf life periods of 12, 9 and 6 d. In general under all the treatments, there was a continuous decline in ascorbic acid content of the fruits especially during ambient holding which might be due to the enzymatic oxidation of L-ascorbic acid to dehydroascorbic acid. The role of CaCl2 in restricting ripening is well established and might have led to higher retention of ascorbic in treated fruits.

The titratable acidity of the fruits decreased linearly throughout the storage period in all the treatments while, the minimum acidity was recorded in control fruits after each simulated shelf life period under ambient condition. The treated fruits usually had higher acidity with 40 and 30 g kg-1 CaCl2 treatments for 30 min being most effective as they recorded the highest acidity values during stimulated shelf life periods of 12, 9 and 6 d after 30, 60 and 90 of cold storage. Similar findings of decrease in acidity of pear fruits during storage were reported earlier by Nath. The reduction in the titratable acidity of the fruits during storage is often ascribed to the conversion of organic acids into sugars and their derivatives and their further utilization as the respiratory substrates.

Pectinmethyle Esterase and Polygalacturonase Activity

During fruit softening, different enzyme systems (primarily PME and PG) are activated within the fruit tissues which causes solubilization and depolymerization of pectin and hemicellulose and thus leads to wall loosening and ultimately loss of the fruit firmness. PMEs play an important role in determining extent to which demethylesterified pectic polysaccharides are accessible to degradation by PG. The activity of Pectin Methyl Esterase (PME) exhibited a notable ‘up-down’ trend during storage and in control fruits PME activity was reported to be the highest 3.98 units/mL after 60 d before it declined to 2.98 units/mL after 90 d. Further, 40 and 30 g kg-1 CaCl2 dip treatment for 30 min effectively resulted in lowest PME activity during ambient shelf life periods. PG activity continued to rise with progression in storage and was most evident in the controls. This behavior suggests that enzymes (PME and PG) actively participate in mid- and late-stage softening which ultimately leads to onset of senescence which is pre expected. Different CaCl2 treatments recorded a more gradual increase in PG activity with a non-significant deference in PG activity of fruits treated with 40 g kg-1 CaCl2 for 30 and 20 min and 3 g kg-1 CaCl2 for 20 min respectively.

Pectin Methyl Esterase (PME) activity results in removal of methyl esters from galacturonic acid chain thus, makes it susceptible to action of Polygalacturonase (PG) which initiates linear breakdown of pectin molecules resulting in fruit softening. The initial increase in PME activity might be due to climacteric rise due to synthesis of different enzymes to facilitate ripening. The increase in PG and PME activity during ripening has also been reported earlier in pear, peach, guava (1) and tomato fruits.

Calcium content of the fruits increased significantly during cold storage and shelf life periods under ambient holdings. The fruits treated with 40 g kg-1 CaCl2 for 30 significantly recorded the highest calcium content (1.438 ppm) after 90 d of cold storage. Calcium content of fruits treated with different concentrations of CaCl2 was higher compared with control fruits and was proportional to the concentration and dipping time of CaCl2 used. The higher calcium content in treated fruits is correlated with slow cellular degeneration absorption of higher amount of calcium by the fruits. Calcium applied as post-harvest dipping treatment penetrates the fruit tissues primarily through lenticels and increases Ca content of tissues, mainly middle lamella region where it accumulates in form of calcium pectate and helps to hold the cellular network intact.

The untreated control fruits retained the lowest volume of total phenols 32.86 mg GAE/100g while, the fruits receiving the calcium treatment generally retained higher phenolic content. There was a general decline in total phenolic content of the fruits irrespective of the storage conditions as is depicted in the graph in Figure 1. The fruits treated with 40 g kg-1 CaCl2 for 30 min had highest amount of total phenols (32.15 mg GAE/100 g) after 120 d, while difference in total phenol content of fruits treated with 30 g kg-1 CaCl2 for 30 min and 40 g kg-1 CaCl2 for 20 min was also non significant (32.088 and 31.98 mg GAE/100g). The decline in phenolics with advancement of storage under different atmosphere can be attributed to the Polyphenol Oxidase (PPO). The slower breakdown of phenolics in the fruits treated with different concentrations of calcium might be due to restricted activity of browning enzymes especially polyphenol oxidase which may result in breakdown/polymerization of the phenolics. Similar changes in phenolic content of fruits during storage after various postharvest treatments have been reported earlier by Simple and Bhatnagar.

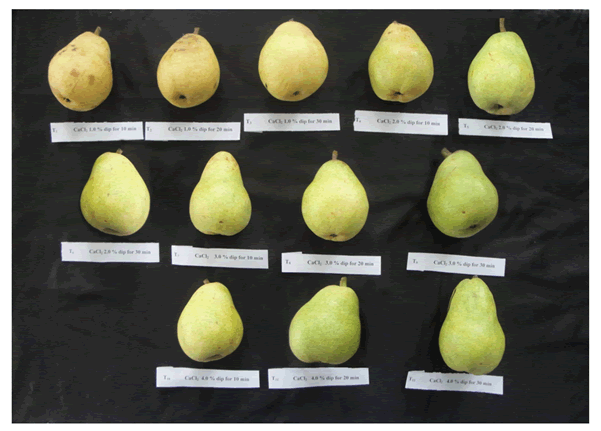

The overall acceptability rating of the pear fruits was recorded as the mean values for changes in colour, flavor and texture which started with an initial increase followed by a decline during storage under various environmental conditions. Fruits treated with 40 and 30 g kg-1 CaCl2 for 30 min exhibited highest color (Figure 1), texture, taste, aroma and thus overall acceptability scores and such fruits were acceptable up to 12, 9 and 3 d shelf life period under ambient conditions after 30, 60 and 90 d of cold storage. The untreated fruits could retain acceptable quality only up to 6 and 3 d shelf life periods after 30 and 60 d of cold storage while, these fruits undergo rapid ripening changes under ambient conditions and became unacceptable after 90 d of cold storage. The initial increase in sensory score of the fruits might be due to development of appropriate colour, texture and flavor due to changes occurring during ripening while the decline towards completion of storage period could be due to completion of the ripening process and initiation of senescence in fruits [5].

Conclusion

Though in literature a lot of information is available on use of CaCl2 as a potential pre and post harvest agent to retain storage quality of fruits and vegetables both as fresh and as processed form. However, in fresh horticultural commodities like pear fruits exact concentration of CaCl2, treatment time and most importantly behavior of fruits during ambient holdings after periodic cold storage is not better studied. As after harvesting it is not always possible to keep the produce under cold storage further, after cold storage fresh produce will be kept under ambient conditions for retailing. The findings of present study cites the possibility of retaining quality of pear fruits during cold storage and shelf life periods under ambient conditions. It was found that sensory profile of pears treated with 40 and 30 g kg-1 CaCl2 for 30 min dipping time was acceptable up to shelf-life periods of 12, 9 and 3 d after 30, 60 and 90 d of cold storage, respectively. Other potential treatment with comparable findings was 40 g kg-1 CaCl2 dipping for 20 min It was also concluded that fruits lost their acceptability as the firmness values declined below 3.15 kg cm-2, TSS reduced below 10.0 % and the PLW increased beyond 9.00%, which were found to be the threshold limits for fruit consumption in terms of overall acceptability of fruits.

Funding

No funding was received for the study

Acknowledgements

The work has been carried out in post-harvest and physiology laboratory of Department of Food Science and Technology, Dr. YS Parmar University of Horticulture and Forestry, Nauni-Solan (HP), India and the support and facilities provided by the university are fully Acknowledged.

Conflicts of Interest

It is declared that the authors does not have any conflict of interest

References

- Escribano S, Sugimotoa N, Macnishb AJ, et al. Efficacy of liquid 1-Methylcyclopropene to delay ripening of 'Bartlett' pears. Postharvest Biol Technol. 2017;126:57-66.

- Sugar D, Einhorn TC. Conditioning temperature and harvest maturity influence induction of ripening capacity in ‘d’Anjou’ pear fruit. Acta Hortic. 2011;60:121-124.

- Mahajan BV, Singh K, Dhillon WS. Effect of 1-methylcyclopropene (1-MCP) on storage life and quality of pear fruits. J Food Sci Technol. 2010;47:351-354.

- Sajid M, Basit A, Ullah I, et al. Efficiency of calcium chloride (CaCl2) treatment on post-harvest performance of pear (Pyrus communis L.). Pure Appl Biol. 2019;8:1111-1125.

- Shirzadeh E, Kazemi M. Effect of malic acid and calcium treatment on quality charactristics of apple fruit during storage. Am J Plant Physiol. 2011;6:176-182.