Research Article - Journal of Public Health Policy and Planning (2023) Volume 7, Issue 5

Application of Industry 4.0 and digital twin in the field of smart healthcare

Madhab Chandra Jena1*, Sarat Kumar Mishra2 and Himanshu Sekhar Moharana3

1PhD Scholar BPUT, Jajpur, Odisha, India

2Director BCET, Balasore, Odisha, India

3Principal, HIT, Bhubaneswar, Odisha, India

- Corresponding Author:

- Madhab Chandra Jena

PhD Scholar BPUT, Jajpur

Odisha, India

E-mail: madhab_jena@rediffmail.com

Received: 08-Aug-2023, Manuscript No. AAPHPP-23-110745; Editor assigned: 10-Aug-2023, PreQC No. AAPHPP-23-110745 (PQ); Reviewed: 14-Aug-2023, QC No. AAPHPP-23-110745; Revised: 26-Aug-2023, Manuscript No. AAPHPP-23-110745 (R); Published: 07-Sep-2023, DOI: 10.35841/aaphpp- 7.5.192

Citation: Jena MC, Mishra SK, Moharana HS. Application of Industry 4.0 and digital twin in the field of smart healthcare. J Public Health Policy Plan. 2023;7(5):192

Abstract

There is an increasing need for preventive health care as well as precise diagnosis and tailored treatment of different diseases in recent years. Providing customized treatment for each patient and maximizing accuracy and efficiency are main goals of a good healthcare system. The digital twin technology along with Industry 4.0 is being implemented in different industries nowadays in many countries. It is showing significant improvements by maximizing efficiency and reducing wastage in the system. It is also being evaluated and being started in the field of healthcare and the medical industry. This technology can offer innovative solutions for precise diagnosis, preventive health care and personalized treatments. Though there are challenges in data collection, data integration and accurate simulation at this stage, it is speculated that the digital twin will have an increasing foot fall and will be a new platform for health management systems and the medical industry. This article proposes a framework and configuration for using digital twin technology along with Industry 4.0 in health care applications. A case study of this technology was also conducted by applying it on a human being and his health condition has been monitored online by use of technology. It is observed that preventive health care is becoming easy and accurate on a real-time basis. It is obvious that in future, the generations to come will see the digital twin for every human being. As soon as a baby is born, its digital twin will be in cyber space and its healthcare will be looked after with the aid of this technology till its death. But the main challenge will be the privacy of people if it is implemented on a large scale.

Keywords

Industry 4.0, Digital Twin, IOT, Precision Medicine, Healthcare, Big Data.

Introduction

A digital twin is a cybernetic replica of a physical system, process, or product. It acts as a link between the physical and virtual worlds. Digital twin is integrated with Industry 4.0 using sensors to collect real-time data about a physical existence [1]. This data is then used to simulate by applying different analytics, software programming and modeling etc. to know how it will behave in a real case scenario. Different case studies were conducted using different scenarios with varying different parameters to reach a certain state which can help the researchers/engineers/scientists/doctors for effective decision making. Digital twin is also termed as virtual twin, virtual prototyping or digital asset management [2, 3, 4].

A digital twin commences its life by being built by specialists for drawing conclusions and enhancing decision making.

The twin is created so that it can receive input from IOT based sensors gathering data from a physical counterpart. This allows the twins to simulate the physical object in real time. This helps to develop insights to solve potential problems. The twin could also be used as a virtual prototype before making an object. The digital twin technology is being implemented in industry, agricultural field, aerospace engineering etc. to improve efficiency, reliability and fault finding of the systems [2-6].

The developed countries of the world have now started implementing the digital twin technology along with Industry 4.0 in the field of health care and medical science [12].

Industry 4.0 aims to upgrade medical technology by integrating the physical systems with the Internet of Things (IoT), cyberphysical systems (CPSs), big data and cloud computing [5, 7, 8, 9, 15, 16, 21]. The integration of the digital twin with this configuration makes a much more robust platform to monitor the parameters through real-time communication and enables us to take smart decisions by simulation and modeling [9].In this paper the architecture and integration of a digital twin with industry 4.0 is discussed along with a case study is conducted on a patient by which the field application is also tested and concluded that this can be helpful to the human being in great way in coming time with its evolution and advancement.

Materials and Method

Digital twin technology key elements and architecture will be studied in detail along with the integration of digital twin with industry 4.0. The making of the digital twin procedure is also discussed with architecture. The application of industry 4.0 with digital twin is tested on a human being and a model case study was presented and tested its work in the real case application.

Key Elements of Industry 4.0 and digital twin for health care

Key elements of Industry 4.0 and the digital twin structure are the living human body, IOT, digital twin, Cloud computing and simulation. All the four elements are integrated and they interact with the physical systems or living being to create a smart and real-time environment known as Smart Healthcare.

The human being involved in this structure is the patient or the person whose health conditions needs to be monitored on a real-time basis and needs to be treated as per the needed basis, or the person who has already undergone some treatment whose condition needs to be monitored on a real-time basis for generating alarm to create caution for the patient as well as for the concerned doctor in case of any emergency situation arises.

The IoT involves extending internet connectivity to devices like sensors, laptops, computers, tablets, mobile phones etc. at any point of the world to connect, interact, exchange data with the user and physical systems to monitor remotely and take decisions accordingly [10-13].

The digital twin is a replica of the patient whose health condition needs to be monitored. The digital twin of different body parts of the patient is also created in the cyber space for simulation and decision making. The digital twin is prepared as per the procedure mentioned earlier in this paper.

Cloud computing is shared pools of configurable computer systems that can be rapidly accessed over the Internet. Cloud computing relies on sharing of resources to achieve coherence and economies of scale, similar to public utility. Different simulations are conducted by the doctors/researchers with the help of different software, analytics and modeling to arrive at a decision related to the patient’s treatment on this platform.

Digital twin technology is also used for personalized medicine, precision public health and smart medicine manufacturing [11,17,24].

Basic Architecture of Industry 4.0 and digital twin structure

Basically, there are five layers in the architecture of Industry 4.0 integrated with digital twin. These are data acquisition layer, data munging layer, data storage layer, data simulation with analytics layer, user access layer [14,18,19,20,21,22]. These layers are integrated and customized to adopt as per the requirements of the health care and treatment.

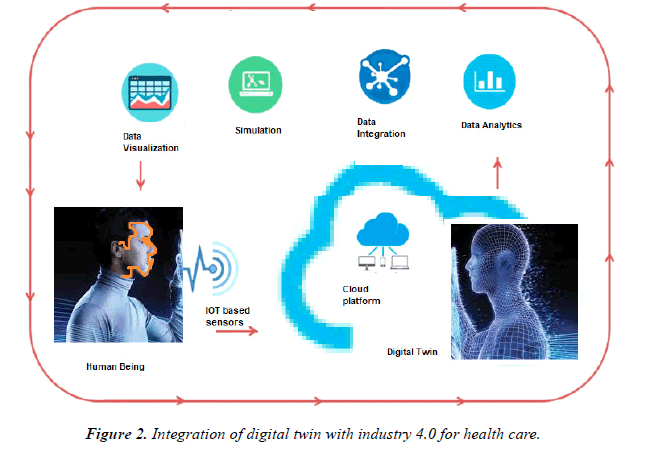

Data acquisition happens through IOT based sensors fitted with the physical human being and the data is transmitted to the cloud server as shown in Figure 2. The acquired data is sent further to the data munging layer [15]. Data storage and management is done through specialized data warehousing systems with backups and disaster recovery systems [14,16].

Data analysis is done as per the different requirements through algorithms and software programs with human intervention for the conclusion and decision making [15].

Manual data collection systems are completely eliminated. The user can access the data by using a user id and password for data protection and privacy [16].

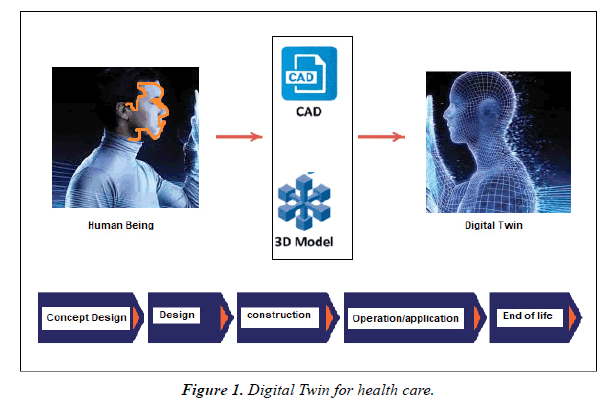

Making of Digital Twin for health care

As shown in figure 1, the digital twin is prepared using AutoCAD and 3D modelling after taking the dimensions of the physical object. The design is first prepared and then virtual prototyping is prepared, then it is crosschecked with the actual physical object [11]. The digital twin can be prepared for the whole human body or different body parts like the heart, kidney, liver etc. The digital twins can be used for analysis and simulation, i.e. simulation of the heart can be done by using fluid dynamics to study the flow of blood and how much pressure can sustain the cardiac system and flow can be monitored with restrictions in the veins and artery. The emergence of digital twin technology will make precision medicine possible in the future. Digital twin technology is already used in medical fields, such as predicting diseases by physical examination and improving accuracy in medical diagnostics [23].

Integration of digital twin with industry 4.0 for health care

After creating the digital twin as per the standard procedure, the digital twin will be saved in the cyber space with a separate ID given to the particular patient whose digital twin is created and saved in the cloud. All the associated information of the patient is also saved in the same folder with a detailed history related to health care. For the collection of required data, IOTbased sensors are fitted in the human body as shown in figure 2. The sensors send the data through wireless technology to the server on a cloud platform. The data is stored in the cloud in the same folder as created for the patient and integrated with the digital twin. With the help of different software programming and algorithms, simulation is carried out with data analytics and different mathematical modelling. The data can also be visualized by the user at any point of time for observation and analysis. The alarm system can also be integrated with the collected data which will send alarms to the user based on the set parameters so that the user can check immediately with a given user id and password through mobile phone, laptop, desktop etc. and take immediate decisions according to the alarms and observed data from the system. The system can be useful for preventive health care and corrective health care systems, i.e. a patient has already gone through some treatment or surgery etc. whose health condition required to be checked on real time basis.

Case study on implementation of industry 4.0 and digital twin

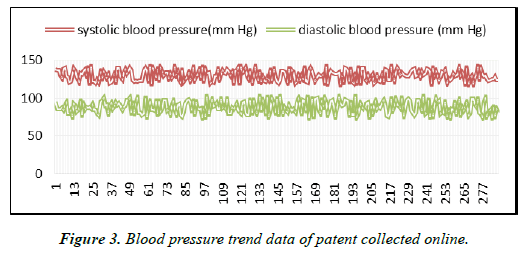

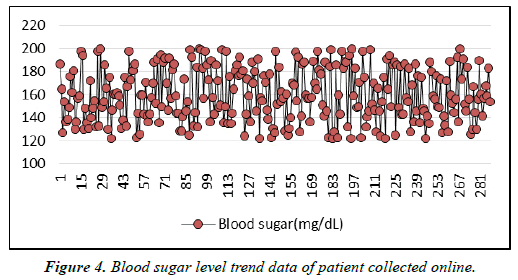

The study was conducted on a human being using different wearable sensors fitted in his body parts to monitor different data related to parts of the health condition of a person for a week. The sensors for measuring blood pressure, blood sugar and heartbeat. The data is then sent to the server through wireless sensors. The data can be monitored though the website created for digital twins in virtual space. The person having the login and password can enter space and he can check his health condition online and also historical data can be retrieved. The minimum data logging frequency by the sensor is every 5 minutes. It can be set into different frequencies as per the requirement on a needed basis.

The alarms can be set for the reading going out of range that can be used for alarming the person which can be sent to their mobile devices to create a caution for the abnormal health condition.

As shown in Figure 3, the historical data collected in the system is being crosschecked where it is observed that the diastolic blood pressure went up to 142 mm Hg and the systolic blood pressure went down to 79 mm Hg. The data is collected for one day and the frequency for data logging is set for every 5 minutes.

As shown in Figure 4, the historical data collected in the system is being crosschecked where it is observed that the blood sugar level has gone up to 200 mg/dL and the blood sugar level has gone down to 122 mg/dL. The data is collected for one day and the frequency for data logging is set for every 5 minutes.

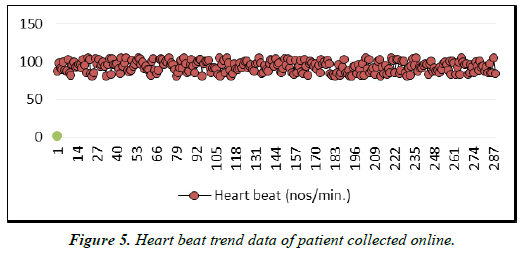

As shown in Figure 5, the historical data collected in the system is being crosschecked where it is observed that the heart beat level has gone up to 105 numbers per minute and the heart beat level has gone down to 81 numbers per minute. The data is collected for one day and the frequency for data logging is set for every 5 minutes.

Observation and Discussion

From the above study it is clear that the application of industry 4.0 and digital twin is in the evolving stage in the field of health care. The architecture discussed in the thesis is used for a single case scenario. Different architectures can be developed as per the requirements of the specific case. It will be used as a reference for developing other architectures. The case study conducted on a patient also represents a basic application of the digital twin technology along with Industry 4.0. Different data related to blood pressure, blood sugar level, heart beat has been collected online on a real-time basis from the patent. The alarm is also generated and received by the patient on his mobile phone as per the set value for all the parameters i.e. blood pressure, heart beat and blood sugar. This data can be used by doctors for diagnosis and treatment. This type of data for a prolonged period can be really helpful and used for simulation and drawing inference by using different mathematical and logical algorithms.

Limitations

Despite its unique advantages due to the unavailability of real-time biomechanical analysis, it is difficult to analyze without a complete automated data system which needs to be fed manually. Complex digital twin models with high accuracy and flexibility like soft tissues are still a limitation to constructing in 3D modeling. Online data collection on a realtime basis by using sensors without any interruption is still a challenge as human beings and their privacy are involved in this framework.

Conclusion

It is evident from the above study that after implementing smart healthcare backed by Industry 4.0 and digital twin there is a significant benefit and achievement in the field of preventive as well as corrective healthcare and treatment. Although this technology is at its early stage of implementation, having its own limitations, it is still expected that the whole world is going to adopt it in the coming future to fulfill the growing needs for better and smart health care and treatment. So, it is better to be a part of this journey in the early stage to cope with the whole world by fulfilling the growing demand of people in the field of healthcare and the medical industry. The future scope of the study would be to implement the digital twin technology in a particular organ of the human body like the heart or kidney and conduct the simulation and modeling with different conditions for decision making.

References

- Tao F, Zhang M, Nee AY. Digital twin driven smart manufacturing. 2019.

- Glaessgen E, Stargel D. The digital twin paradigm for future NASA and US Air Force vehicles. In53rd AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference 20th AIAA/ASME/AHS adaptive structures conference 14th AIAA 2012.

- Tao F, Zhang H, Liu A, et al. Digital twin in industry: State-of-the-art. IEEE Trans Industr Inform. 2018;15(4):2405-15.

- Cimino C, Ferretti G, Leva A. Harmonising and integrating the Digital Twins multiverse: A paradigm and a toolset proposal. Comput Ind. 2021;132:103501.

- Qi Q, Tao F. Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. IEEE Access. 2018;6:3585-93.

- Burgun A. Basis and perspectives of artificial intelligence in radiation therapy. Cancer Radiother. 2019;23(8):913-6.

- Lee J, Bagheri B, Kao HA. A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manuf Lett. 2015;3:18-23..

- Lasi H, Fettke P, Kemper HG, et al. Industry 4.0. Bus Inform Syst Eng. 2014;6:239-42.

- Wang S, Wan J, Zhang D, et al. Towards smart factory for industry 4.0: a self-organized multi-agent system with big data based feedback and coordination. Comput Netw. 2016;101:158-68..

- Brown E. Who needs the Internet of Things? 2016.

- Brown E. 21 Open Source Projects for IoT. 2016.

- Internet of Things Global Standards Initiative. Internet of things global standards initiative. 2015.

- Hendricks D. The Trouble with the Internet of Things–London Datastore. 2015.

- Arvind A, Bourne D. Architecture for industry 4.0-based manufacturing systems. Degree of Master of Science in Robotics. School of Computer Science Carnegie Mellon University. 2016.

- Wenzel R, Van Quaquebeke N. The double-edged sword of big data in organizational and management research: A review of opportunities and risks. Organ Res Methods. 2018;21(3):548-91.

- Tonidandel S, King EB, Cortina JM. Big data methods: Leveraging modern data analytic techniques to build organizational science. Organ Res Methods. 2018;21(3):525-47.

- Kamel Boulos MN, Zhang P. Digital twins: from personalised medicine to precision public health. J Pers Med. 2021;11(8):745.

- Schroeder GN, Steinmetz C, Pereira CE, et al. Digital twin data modeling with automationml and a communication methodology for data exchange. IFAC-PapersOnLine. 2016;49(30):12-7.

- Zhang P, Tao YZ, Zhang Z. Survey of several key technologies for 5G. Journal on Communications. 2016;37(7):15-29.

- Yao B, Zhou Z, Wang L, et al. A function block based cyber-physical production system for physical human–robot interaction. Journal of manufacturing systems. 2018;48:12-23.

- Tao F, Cheng J, Qi Q, et al. Digital twin-driven product design, manufacturing and service with big data. The International Journal of Advanced Manufacturing Technology. 2018;94:3563-76.

- Mandolla C, Petruzzelli AM, Percoco G, et al. Building a digital twin for additive manufacturing through the exploitation of blockchain: A case analysis of the aircraft industry. Computers in industry. 2019;109:134-52.

- Price L. The digital health hype cycle 2019. Healthcare. Digital. 2020.

- FDA U. Paving the way for personalized medicine. FDA's Role in a new Era of Medical Product Development. US Department of Health and Human Services. 2013:1-61.

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref

Indexed at, Google Scholar, Cross Ref